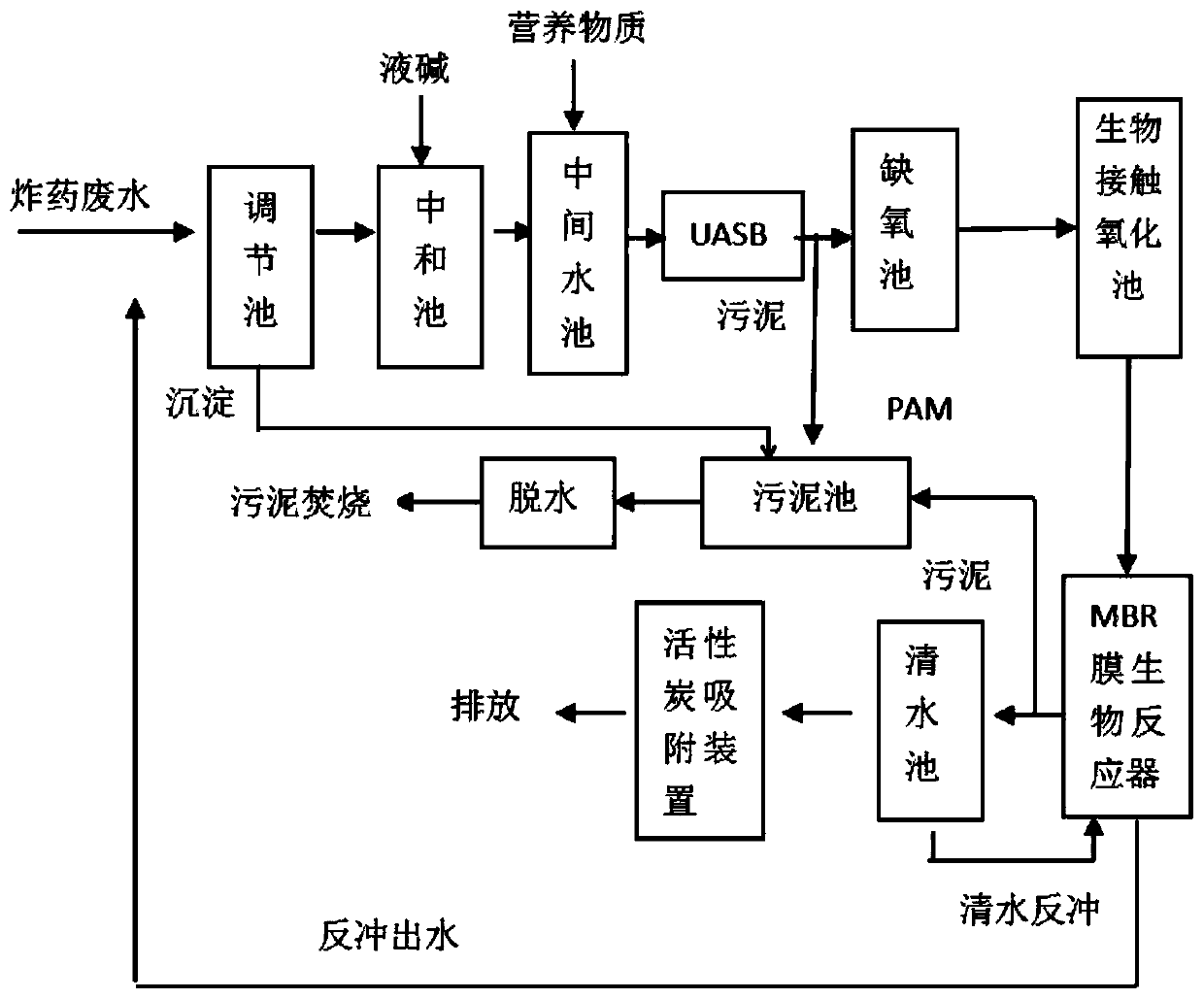

Treatment method of nitro-nitrate-based explosive wastewater

A treatment method and technology for explosive wastewater, applied in water/sewage treatment, biological water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problem of high treatment costs, effluent indicators that cannot meet national discharge requirements, and high labor intensity And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

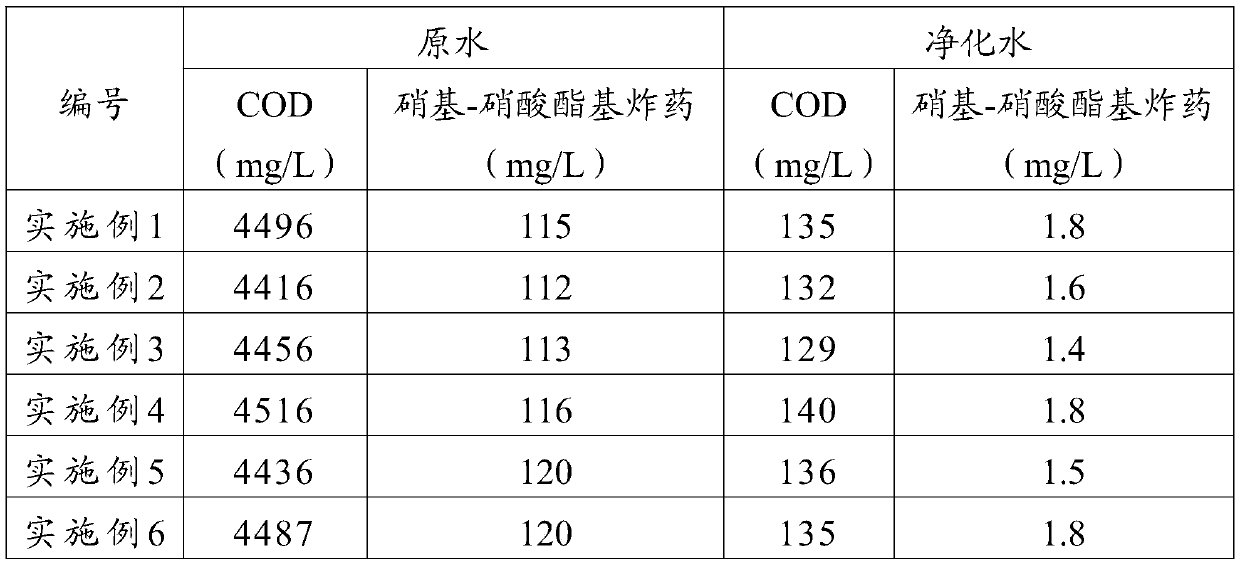

Embodiment 1~6

[0049] Put the nitro-nitrate-based explosive waste water (the water quality is as in the "raw water" column in Table 1) into the regulating tank for homogeneous and uniform quantity, and the homogeneous and uniform quantity of effluent water quality is: COD: 4000 ~ 5000mg / L , pH value: 1-3; then adjust the pH value of the homogeneous and even amount of effluent in the neutralization tank to 4-5; the effluent of the neutralization tank is mixed with nutrients in the intermediate tank to obtain wastewater to be biochemically treated; the nutrient The substance is glucose, and the carbon-nitrogen ratio of the wastewater to be biochemically treated is 14:1;

[0050] Pass the wastewater to be biochemically treated into an upflow anaerobic sludge bed reactor for anaerobic treatment, wherein the sludge content in the upflow anaerobic sludge bed reactor is maintained at 40-60g / L, and the temperature The temperature is 22°C, and the residence time in the upflow anaerobic sludge bed rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com