Preparation method for tissue engineering cartilage scaffold

A tissue engineering and cartilage technology, which is applied in the technical field of chemical cross-linking, can solve the problems of decreased mechanical strength, inability of dynamic mechanical culture of cells, and reduced mechanical retention of scaffolds, and achieves enhanced mechanical properties, controllable degradation rate, The effect of reducing the degradation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

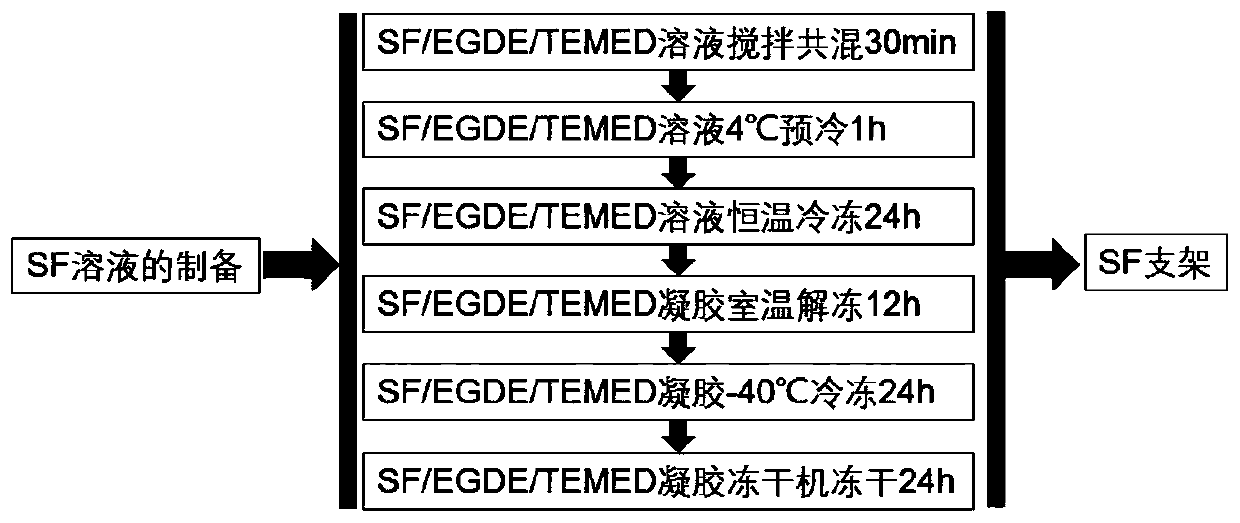

[0046] A kind of preparation method of tissue engineering cartilage scaffold of the present invention, see figure 1 As shown, its implementation steps are as follows:

[0047] Step (1): Preparation of silk protein solution

[0048] The "silk protein" is a natural fibrous protein derived from silkworm cocoons; the silk protein solution is prepared by the following method:

[0049] 1) 10g NaHCO 3 Dissolve in 2 liters (L) of ultrapure water to make 0.5% NaHCO 3 solution, heated to boiling;

[0050] 2) 10g shredded cocoons are put into NaHCO 3 In solution (boiling), cook for 1 hour (h);

[0051] 3) Take out the silk that has been boiled for 1 hour, and rinse it 5 times in ultrapure water;

[0052] 4) Take out the silk, unfold it on a clean tray, place it in an oven at 45°C, and dry it;

[0053] 5) Dissolve 8g of dried silkworm cocoons in 100ml of LiBr (9.3mol / L), cook in a water bath at 40°C (3h) until dissolved;

[0054] 6) Filter the dissolved silk protein solution into ...

Embodiment ( 1

[0066] Embodiment (one): the preparation of silk protein solution

[0067] The "silk protein" is a natural fibrous protein derived from silkworm cocoons; the silk protein solution is prepared by the following method:

[0068] 1) 10g NaHCO 3 Dissolve in 2L ultrapure water to make 0.5% NaHCO 3 solution, heated to boiling;

[0069] 2) 10g shredded cocoons are put into NaHCO 3 In the solution (boiling), cook for 1h;

[0070] 3) Take out the silk that has been boiled for 1 hour, and rinse it 5 times in ultrapure water;

[0071] 4) Take out the silk, unfold it on a clean tray, place it in an oven at 45°C, and dry it;

[0072] 5) Dissolve 8g of dried silkworm cocoons in 100ml of LiBr (9.3mol / L), cook in a water bath at 40°C (3h) until dissolved;

[0073] 6) Filter the dissolved silk protein solution into the Erlenmeyer flask with double-layer gauze;

[0074] 7) Put the filtered silk protein solution into a dialysis bag with a molecular weight cut-off of 8000-14000, and dialyze...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com