Three-dimensional seawater evaporator and applications thereof

A seawater evaporation, three-dimensional technology, applied in the field of material technology and seawater desalination, can solve complex problems and achieve the effects of good weather resistance, high evaporation efficiency and high retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

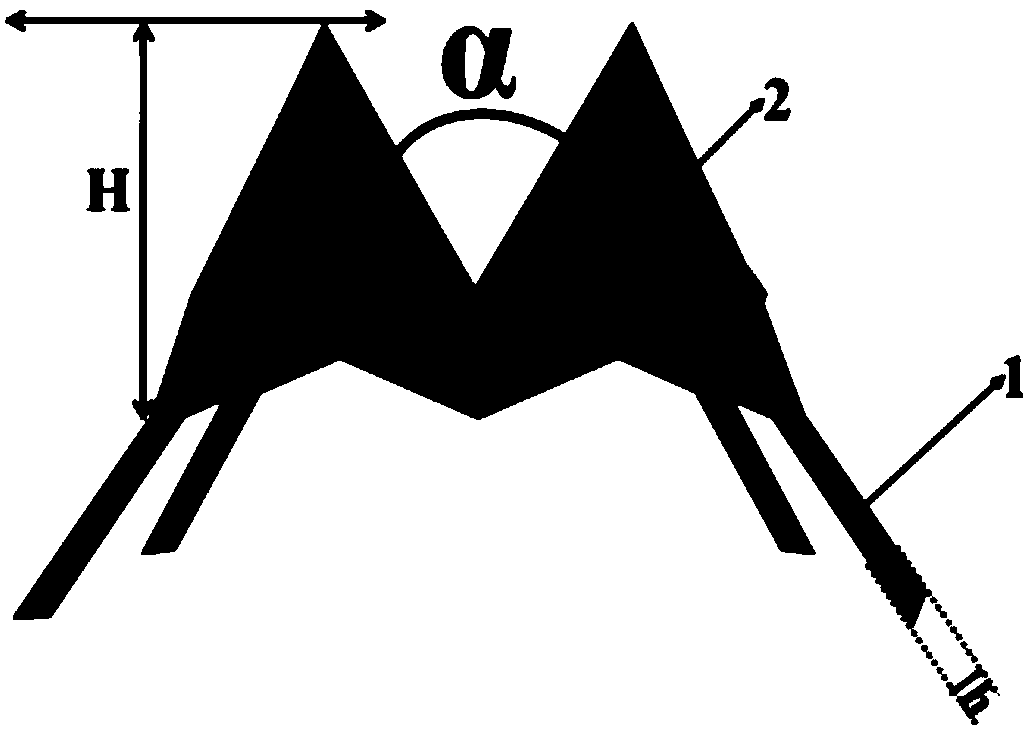

[0049] (1) The structure of the channel. Quadrilateral, the length is 0.05m, the width is 1cm, and the height of right triangle cutting is 0.01m;

[0050] (2) The composition of the channel. The texture is a plain cotton fabric.

[0051] (3) The structure of the reactor unit. Divided into four structural units, the length of each structural unit is 5cm, the height is 0.01m, and the angles α between the structural units are 30°, 50°, 70°, and 90° respectively.

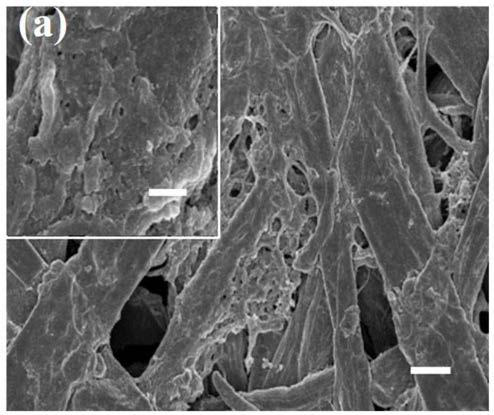

[0052] (4) Composition of the reactor unit. The smoothness is 5s, the moisture content is 2%, the microscopic appearance is zigzag, and the composite paper is modified by N-polypyrrole-polyacrylic acid copolymer with a number average molecular weight of 2000.

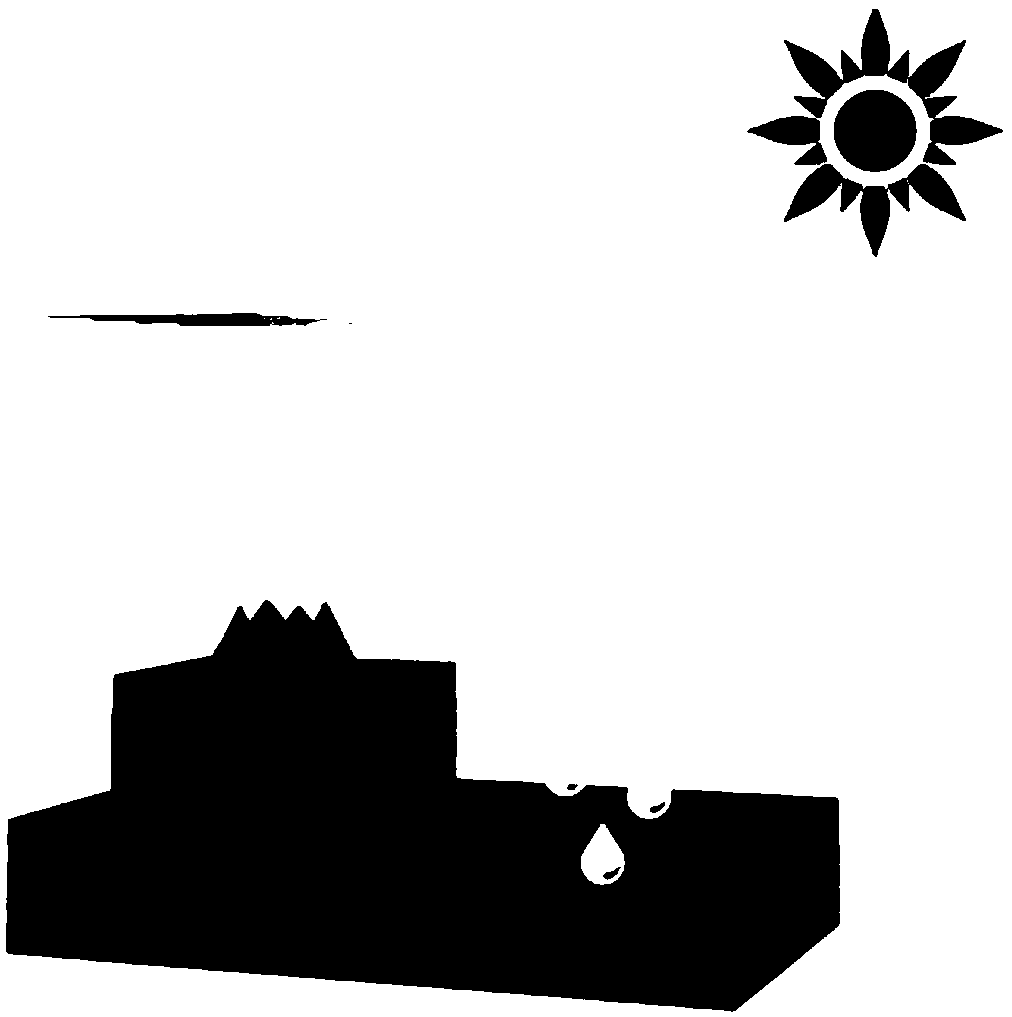

[0053] The three-dimensional seawater evaporator obtained in this example was subjected to morphology and wettability tests, and it was found that after modification, the hydrophilicity was enhanced, which was beneficial to the evaporation of water vapor (res...

Embodiment 2

[0055] (1) The structure of the channel. Quadrilateral, the length is 0.3m, the width is 5cm, and the height of right triangle cutting is 0.03m;

[0056] (2) The composition of the channel. The texture is a honeycomb cotton fabric.

[0057] (3) The structure of the reactor unit. It is divided into four structural units, the length of each structural unit is 10cm, the height is 0.5m, and the angles α between the structural units are 40°, 60°, and 80° respectively.

[0058] (4) Composition of the reactor unit. The smoothness is 8s, the water content is 4%, the microscopic appearance is thread-shaped, and the corrugated paper modified with S-polyaniline-polyvinyl alcohol with a number average molecular weight of 5000 is used.

[0059] The three-dimensional seawater evaporator obtained in this example was subjected to morphology and wettability tests, and it was found that after modification, the hydrophilicity was enhanced, which facilitated the evaporation of water vapor. F...

Embodiment 3

[0061] (1) The structure of the channel. Quadrilateral, the length is 0.3m, the width is 5cm, and the height of right triangle cutting is 0.03m;

[0062] (2) The composition of the channel. Cotton fabric with a twill texture.

[0063] (3) The structure of the reactor unit. It is divided into four structural units, the length of each structural unit is 30cm, the height is 1m, and the angles α between the structural units are 45°, 65°, and 85° respectively.

[0064] (4) Composition of the reactor unit. The smoothness is 15s, the moisture content is 6%, the microscopic appearance is ladder-shaped, and kraft paper modified with Si-polypyrrole-polyethylene glycol with a number average molecular weight of 20,000 is used.

[0065] The three-dimensional seawater evaporator obtained in this example was subjected to morphology and wettability tests, and it was found that after modification, the hydrophilicity was enhanced, which facilitated the evaporation of water vapor. Further, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Smoothness | aaaaa | aaaaa |

| Smoothness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com