Wastewater treatment method for synchronously removing organic matters, sulfate radicals, heavy metals and total nitrogen

A technology for wastewater treatment and organic matter, applied in metallurgical wastewater treatment, textile industry wastewater treatment, biological water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

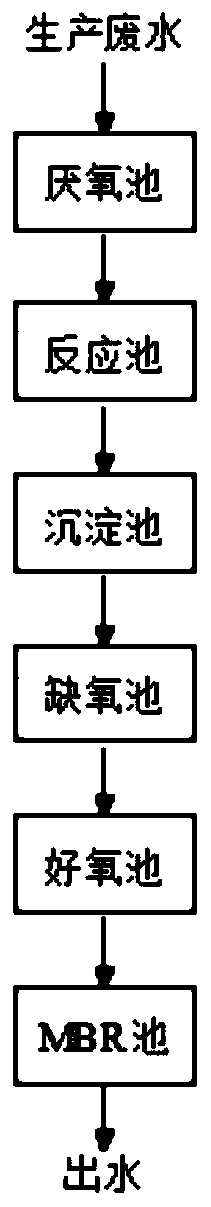

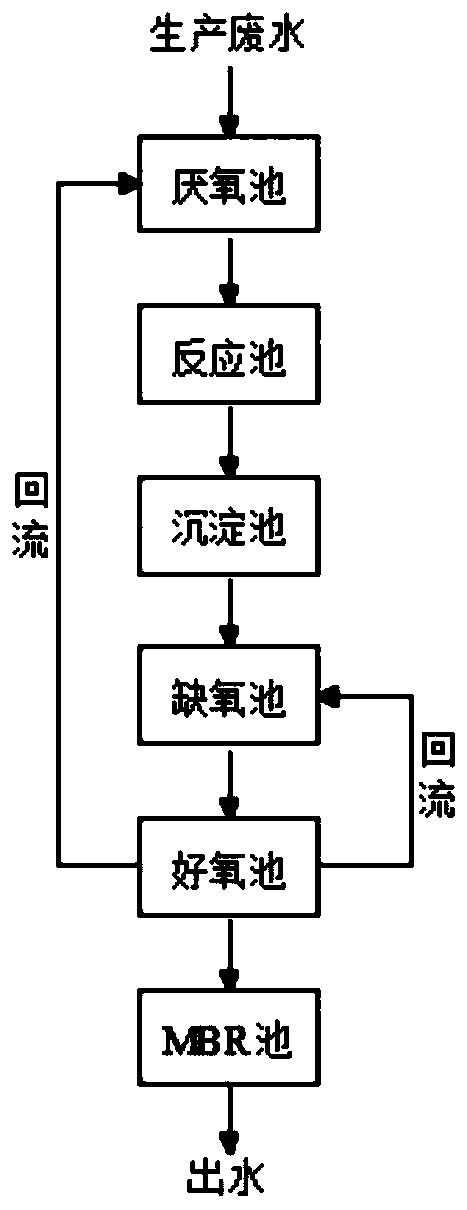

[0037] Such as figure 1 Shown, the present invention a kind of waste water treatment technology that synchronously removes organic matter, sulfate radical, heavy metal and total nitrogen, adopts waste water treatment device to be anaerobic pond, reaction pond, sedimentation pond, anoxic pond, aerobic pond and MBR pond, and Sequential connections via pipes;

[0038] (1) The waste water first enters the anaerobic tank, and the organic matter in the waste water is used as an electron donor in the anaerobic tank, and sulfate-reducing bacteria will produce SO in the waste water 4 2- Revert to S 2- , S and SO 3 2- ; The inoculum volume (L or m) of the sulfate-reducing bacteria 3 ) and the effective volume of the anaerobic pool (L or m 3 ) ratio is 1: 10, and the sulfate-reducing bacteria of described inoculation is the sulfate-reducing bacteria (OD600≈1.0) that is in logarithmic growth phase; Soft packing, combined packing or MBBR biological packing are installed in the descri...

Embodiment 11

[0061] a. Take the pretreated effluent of a certain printing and dyeing wastewater as raw water, and the quality of the raw water is COD=780mg / L, Cu 2+ =1.54mg / L, total nitrogen=145mg / L, SO 4 2- =1350mg / L;

[0062] b. The hydraulic retention time of the anaerobic tank is set to 12h;

[0063] c. In the reaction tank, add NaOH to adjust the pH to 7.5, then add PAC100mg / L and APAM0.5mg / L with a molecular weight of 9 million, and set the reaction time to 15min;

[0064] d. The sedimentation time of the sedimentation tank is set to 1.0h;

[0065] e. The hydraulic retention time of the anoxic pool and the aerobic pool are both set to 8h;

[0066] f.MBR membrane flux is 0.4m 3 / m 2 d;

[0067] g. The effluent quality after treatment is, COD=190mg / L, Cu 2+ =0.08mg / L, total nitrogen=92mg / L, SO 4 2- = 1050 mg / L.

Embodiment 12

[0069] a. Take a circuit board waste water as raw water, the raw water quality is COD=323mg / L, Cu 2+ =0.97mg / L, total nitrogen=62mg / L, SO 4 2- =2850mg / L;

[0070] b. The hydraulic retention time of the anaerobic tank is set to 12h;

[0071] c. In the reaction tank, add NaOH to adjust the pH to 7.2, then add PAC100mg / L and APAM0.5mg / L with a molecular weight of 9 million, and set the reaction time to 15min;

[0072] d. The sedimentation time of the sedimentation tank is set to 1.0h;

[0073] e. The hydraulic retention time of the anoxic pool and the aerobic pool are both set to 8h;

[0074] f.MBR membrane flux is 0.4m 3 / m 2 d;

[0075] g. The effluent quality after treatment is, COD=54mg / L, Cu 2+ = 0.05mg / L, total nitrogen = 12mg / L, SO 4 2- =1150mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| ionicity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com