Preparation method of 3-acetamido-N,N-diacetoxyethylaniline

A technology of diacetoxyethylaniline and acetamido, which is applied in the field of organic chemical intermediate product preparation, can solve the problems of long operation time, high energy consumption, and strong smell of acetic acid, and achieve low waste water production, low energy consumption and material consumption, The effect of simple operation control and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

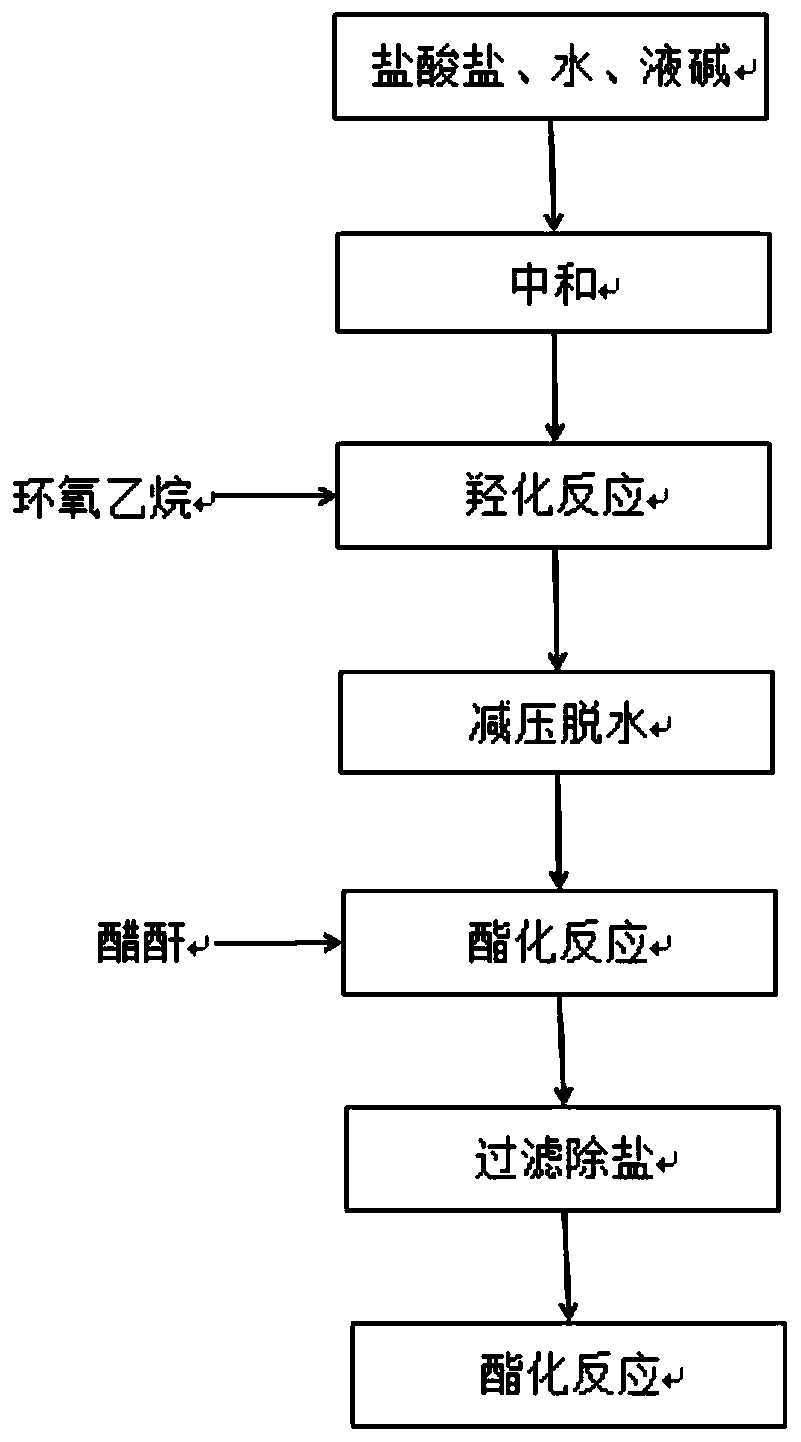

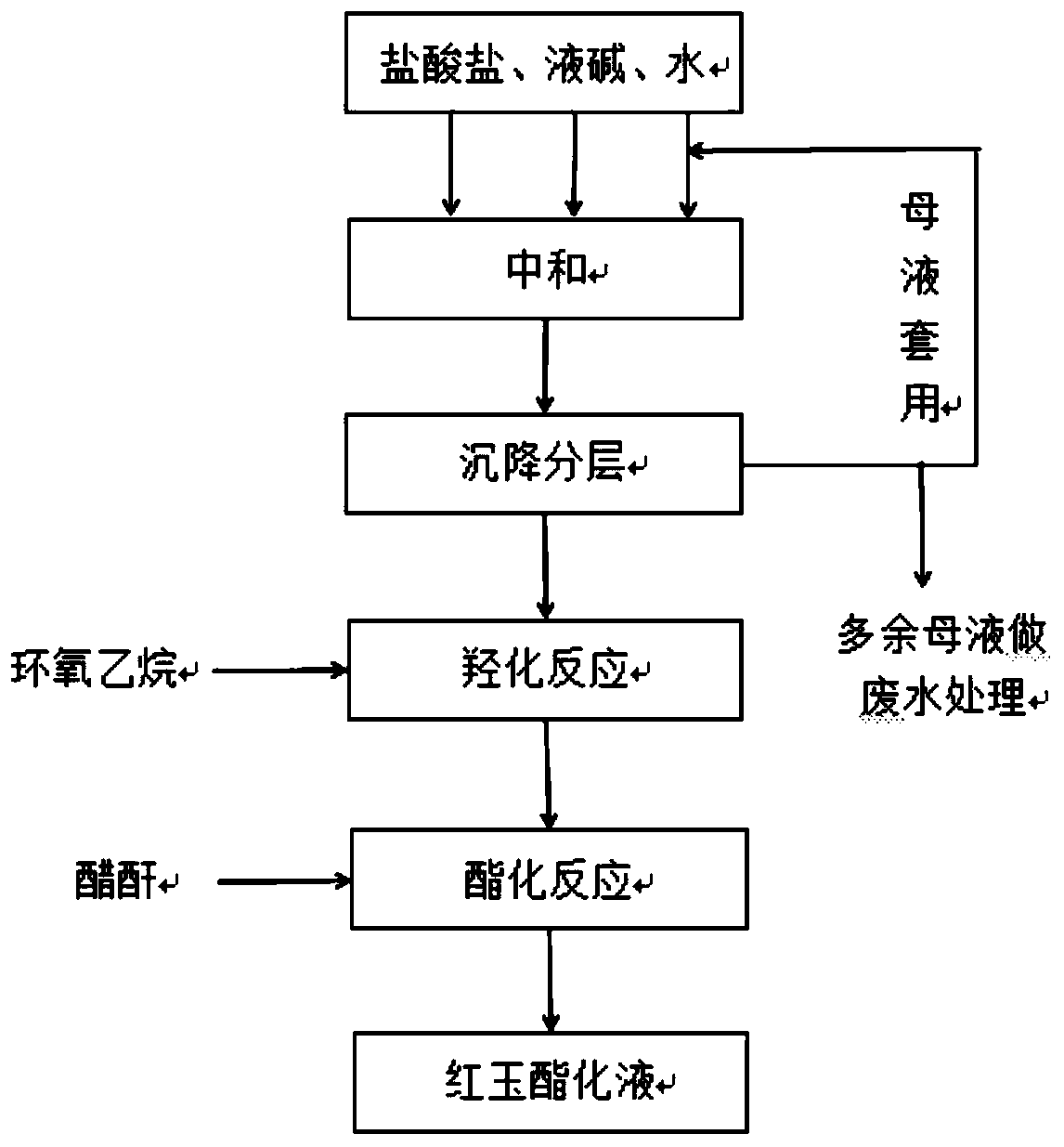

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 is the comparison of the technical solution of the present invention and the technical solution of the prior art during the workbench.

[0037] Add 110g of water into a 500ml four-necked bottle, add 150g of hydrochloride under stirring, heat up to 50°C, evenly add 32% liquid caustic soda dropwise until the end point pH=8-9, continue stirring at 60-65°C for 10min, Retest and adjust pH=8-9 with liquid caustic soda. Transfer the material to a separatory funnel, settle for 10-15min, separate out 180ml of mother liquor, transfer the oil phase into an autoclave, replace the gas in the autoclave with nitrogen three times, raise the temperature to 50°C, and feed ethylene oxide evenly for 7-8h Alkane 77.5g, after the addition, react at 50-55°C for 3.5h. Sampling and analysis showed that the middle class was 1.25%, and the main class was 97.27%. Transfer the material to a 500ml four-necked bottle, raise the temperature to 80°C, add 180g of acetic anhydride slowly o...

Embodiment 2

[0039] Embodiment 2 is mainly aimed at the comparison of ethylene oxide consumption.

[0040] Add 200ml of the mother liquor that has been used continuously for 8 times in a 500ml four-necked bottle, add 150g of hydrochloride under stirring, raise the temperature to 50°C, and evenly add 32% liquid caustic soda until the end point pH=8-9, at 60-65°C Stirring was continued for 10 min, and the test was repeated and the pH was adjusted to 8-9 with liquid caustic soda. Transfer the material to a separatory funnel, settle for 10-15 minutes, separate the oil phase, and filter the mother liquor while it is hot to obtain 44.7g of salt, 256ml of the mother liquor, 200ml for the next batch of experiments, and 56ml of the mother liquor for wastewater treatment. The oil phase was transferred into an autoclave, and the gas in the autoclave was replaced with nitrogen three times, then the temperature was raised to 50°C, and 72g of ethylene oxide was evenly introduced in 7-8h, and reacted at ...

Embodiment 3

[0042] Embodiment 3 is mainly aimed at the comparison of the amount of waste water produced.

[0043] Add 200ml of the mother liquor that has been used continuously for 9 times in a 500ml four-necked bottle, add 150g of hydrochloride under stirring, raise the temperature to 50°C, and evenly add 32% liquid caustic soda until the end point pH=8-9, at 60-65°C Stirring was continued for 10 min, and the test was repeated and the pH was adjusted to 8-9 with liquid caustic soda. Transfer the material to a separatory funnel, settle for 10-15min, separate the oil phase, and filter the mother liquor while it is hot to obtain 43.9g of salt, 258ml of mother liquor, of which 200ml is used for the next batch of experiments, and the remaining 58ml of mother liquor is used for wastewater treatment. The oil phase was transferred into an autoclave, and the gas in the autoclave was replaced with nitrogen three times, then the temperature was raised to 50°C, and 77.5g of ethylene oxide was evenly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com