A kind of preparation method of sodium n-methyl taurate

A technology of sodium methyl taurate and sodium isethionate is applied in the field of preparation of sodium N-methyl taurine, can solve problems such as harsh process conditions, and achieves that the post-processing process is simple and easy to recycle and reuse. , the effect of low temperature and pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The source of the reagent raw material used in the preparation example of the present invention, embodiment and comparative example is as follows:

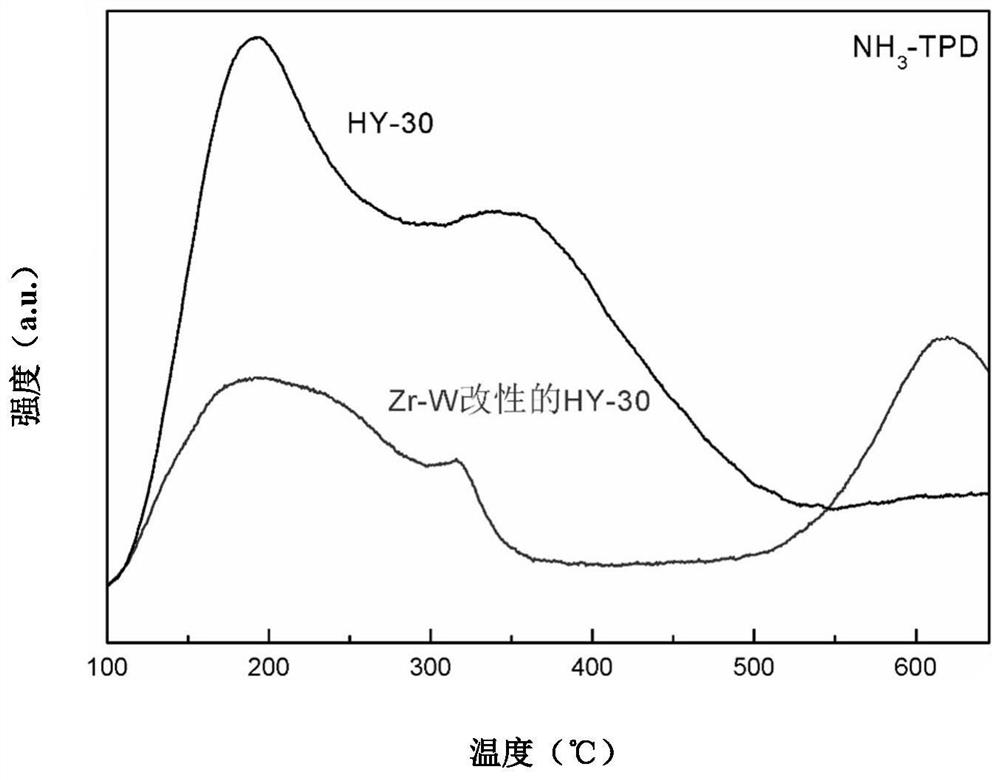

[0034] ZrO(NO 3 ) 2 , (NH 4 ) 2 WO 4 , Anhydrous methylamine was purchased from Shanghai Aladdin Biochemical Technology Co., Ltd.; molecular sieve catalyst HY-30 was purchased from Nankai Catalyst Factory; sodium isethionate was purchased from Sigma-Aldrich; methylamine was purchased from Kedi Chemical Technology Co., Ltd.; Ionic liquids were purchased from Lanzhou Institute of Chemical Physics; aqueous nitric acid solution (30wt%) was purchased from Sinopharm Reagent Co., Ltd.

[0035] Other reagent raw materials are commercially available unless otherwise specified.

[0036] Sodium isethionate and sodium N-methyltaurate were analyzed by derivatization method using liquid chromatography equipped with UV detector. The liquid chromatography is Agilent's 1200 series, equipped with a C18 liquid chromatography column, the...

Embodiment 1

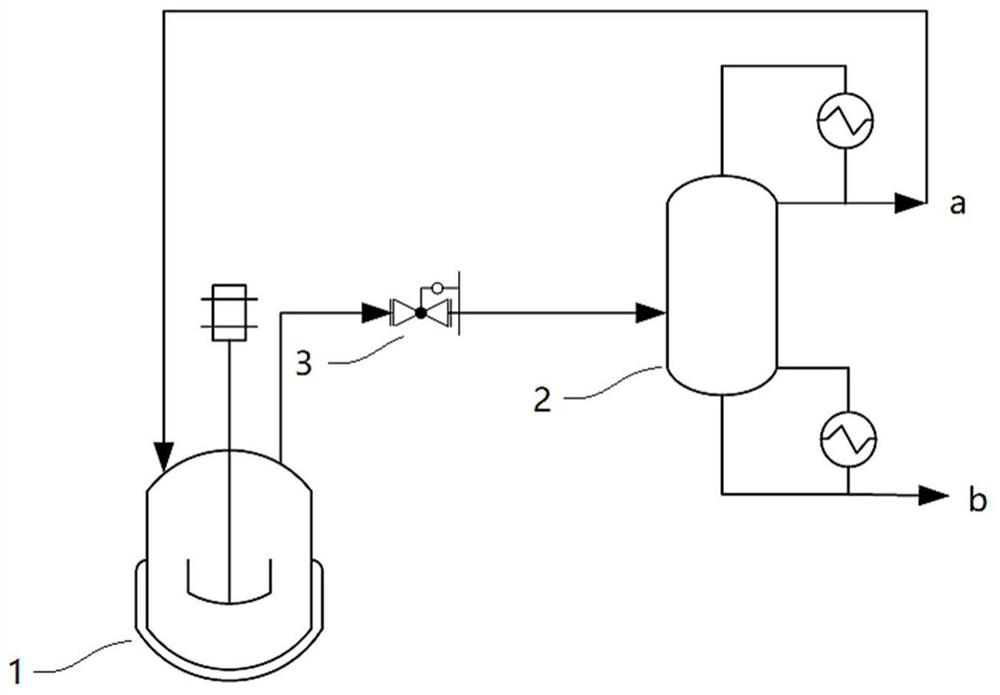

[0041] use as figure 2 The preparation system shown.

[0042] In the reactor, 200g sodium isethionate was dissolved in 1147g [C 6 min][NTf 2 ] in the ionic liquid, then in the reaction system, add the HY-30 catalyst of Zr and W modification of 2g (in terms of metal content, the Zr / W quality accounts for 0.5% of the total mass of the catalyst, and the mol ratio of Zr / W is 1 : 1.5), stir evenly, then add 653g methylamine to the reaction system, after the reactor is airtight, heat up to 200°C, the pressure of the reaction system is controlled at 6.1MPa, the reaction time is 1h, the gas evaporated in the reaction process is reduced The pressure valve decompresses to 5 bar and enters the rectification tower for rectification and separation. The water produced by the reaction is separated from the bottom of the tower, and methylamine is recovered from the top of the tower, which is then applied to the reactor again.

[0043] After the reaction, the temperature of the reaction li...

Embodiment 2

[0049] use as figure 2 The preparation system shown.

[0050] In the reactor, 330g sodium isethionate was dissolved in 1151g [C 6 min][NTf 2 ] in the ionic liquid, then add 16.5g of Zr and W modified HY-30 catalyst (in terms of metal content, the Zr / W quality accounts for 0.8% of the total catalyst mass, and the mol ratio of Zr / W is 1.2:1), stir evenly, then add 718g methylamine to the reaction system, after the reactor is sealed, heat up to 160°C, the pressure of the reaction system is controlled at 5MPa, the reaction time is 1.5h, the gas evaporated during the reaction passes through The pressure reducing valve reduces the pressure to 4 bar and enters the rectification tower for rectification and separation. The water produced by the reaction is separated from the bottom of the tower, and methylamine is recovered from the top of the tower, which is then applied to the reactor again.

[0051] After the reaction is finished, the temperature of the reaction liquid is lowere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com