Gel electrolyte film for secondary battery as well as preparation and application of gel electrolyte film

A gel electrolyte and secondary battery technology, applied in secondary batteries, electrolyte immobilization/gelation, circuits, etc., can solve the problems of reducing chain segment mobility, mechanical strength, poor structural stability and thermal stability, and reducing condensation Gel electrolyte ionic conductivity and other issues, to achieve the effect of weakening the induction, easy to promote, good cycle stability and rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Dissolve 2g PVDF-HFP in 21g acetone, heat to 60℃ and stir for 1h, fully dissolve, and obtain PVDF-HFP solution;

[0042] (2) Add 1g of PEG-4000 to the PVDF-HFP solution prepared in step (1), and stir at 60°C for 1 hour to obtain a PHP solution;

[0043] (3) Add 0.2g Ti 3 C 2 Type MXene powder was dissolved in 2 mL of absolute ethanol, stirred for 12 hours, and ultrasonically dispersed for 2 hours to obtain MXene ethanol solution; add 0.8 mL of MXene ethanol solution to the PHP solution in step (2), and stir at 60°C for 1 hour to obtain PHPM Solution

[0044] (4) Using solution casting technology, take 10mL of PHPM solution and 10mL of PVDF-HPF solution prepared in step (1) and cast them in a polytetrafluoroethylene mold. After standing in the air for 30 minutes, the film is formed, and then transferred to a vacuum oven After drying at 60°C for 12 hours, the gel electrolyte film and PVDF-HFP film were obtained accordingly.

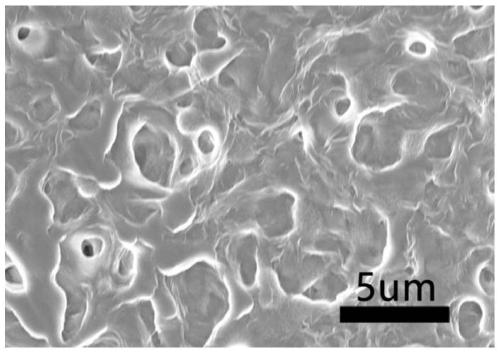

[0045] From figure 1 It can be seen that the PVDF...

Embodiment 2

[0052] (1) Dissolve 2g PVDF-HFP in 21g acetone, heat to 60℃ and stir for 1h, fully dissolve, and obtain PVDF-HFP solution;

[0053] (2) Add 1g of PEG-4000 to the PVDF-HFP solution prepared in step (1), and stir at 60°C for 1 hour to obtain a PHP solution;

[0054] (3) Add 0.2g Ti 3 C 2 Type MXene powder was dissolved in 2 mL of absolute ethanol, stirred for 12 hours, and ultrasonically dispersed for 2 hours to obtain MXene ethanol solution; add 0.4 mL of MXene ethanol solution to the PHP solution in step (2) and stir at 60°C for 1 hour to obtain PHPM Solution

[0055] (4) Using solution casting technology, take 10 mL of PHPM solution and cast it in a polytetrafluoroethylene mold. After standing in the air for 30 minutes to form a film, it is transferred to a vacuum oven and dried at 60°C for 12 hours to obtain a gel electrolyte film. .

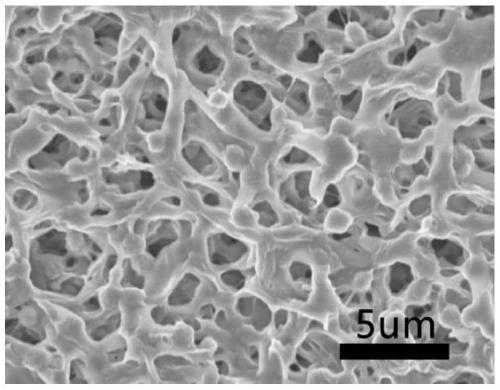

[0056] The SEM characterization shows that the prepared gel electrolyte film has obvious pore structure, and the thickness of the gel electrolyte fi...

Embodiment 3

[0063] On the basis of Example 2, the volume of the MXene ethanol solution in step (3) was modified from 0.4 mL to 0.6 mL, and the other steps and conditions were unchanged to obtain a gel electrolyte membrane.

[0064] SEM characterization shows that the prepared gel electrolyte film has obvious pore structure, and the thickness of the gel electrolyte film is 98 μm.

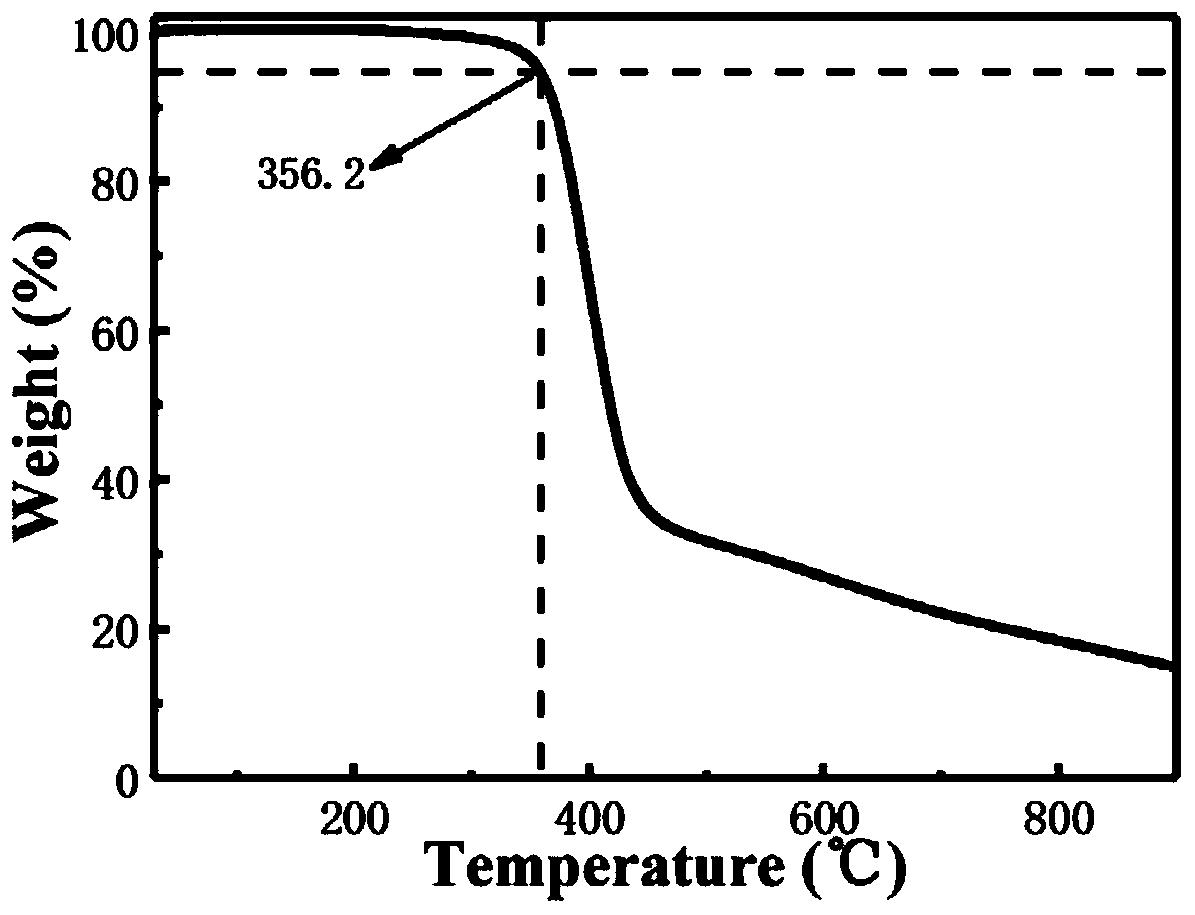

[0065] The thermal performance test of the prepared gel electrolyte film shows that its thermal decomposition temperature is above 350°C, and it has good thermal stability.

[0066] The gel electrolyte membrane prepared in this example was used to assemble a sodium-gel electrolyte-sodium symmetrical battery at 0.1mA / cm 2 The polarization test is carried out at a current density of 0.5%. The test results show that after 1200 hours of sodium deposition / stripping, the polarization voltage is below 75mV, indicating that the prepared gel electrolyte film can inhibit the growth of sodium metal dendrites.

[0067] The gel elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com