Lithium sheet with double-phase surface protection layer, and production method and application thereof

A protective layer and lithium sheet technology, which is applied in the field of lithium sheets with a dual-phase surface protective layer, can solve the problems that hinder the commercialization of lithium-sulfur batteries with high energy density, increase the quality of anodes, and reduce the energy density of batteries. Growth of dendrites, effects of improving stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

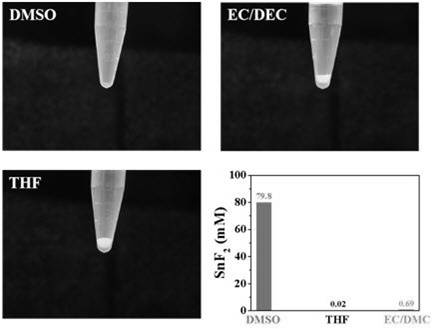

[0035] First, 31.3 mg SnF 2 Dissolve in 2 mL DMSO, THF or EC / DEC (volume ratio 1:1), detect SnF 2 Solubility in different solvents, such as figure 2 As shown, the highly polar DMSO solvent has an effect on SnF 2 There is better solubility, therefore, choose DMSO as SnF 2 The solvent in situ constructs a dual-phase surface protection layer on the surface of lithium metal.

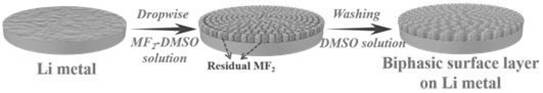

[0036] In situ construction of a dual-phase surface protection layer on the surface of lithium metal, the process is as follows:

[0037] (1) Construction of surface protection layer: according to SnF 2 Prepare dimethyl sulfoxide solutions at concentrations of 10 mM, 20 mM, and 50 mM in sequence, and add 100 μL of the solution to the surface of a lithium sheet covered with a glass fiber diaphragm (the diameter of both the lithium sheet and the glass fiber is 16 mm). Stand still for 30 minutes;

[0038] (2) Cleaning of the surface protective layer: wash the lithium sheet treated in step (1) with dimethyl...

Embodiment 2

[0044] The difference from Example 1 is that the positive electrode uses S-loaded carbon paper, and the preparation process of S-loaded carbon paper is as follows: S and KB carbon are weighed at a mass ratio of 7:3 and ground in a mortar for 0.5 h to 1 h , then add polyvinylidene fluoride, the mass ratio of the sum of S and KB to polyvinylidene fluoride is 9:1, then add N-methylpyrrolidone as a grinding aid, grind for two hours, and evenly apply it on 1.13 cm 2 On the surface of carbon paper (diameter 12mm), after vacuum drying at 80°C for 11 h, a lithium-sulfur battery cathode loaded with S was successfully obtained, and the S loading was about 2 mg.

[0045] In the composition, lithium metal anodes with and without a dual-phase surface protection layer were assembled with carbon paper loaded with S, and the electrolyte was 1 / 1 of 1 M LiTFSI 1,3-di Oxycyclopentane and diethylene glycol dimethyl ether solution, the volume is 60 μL.

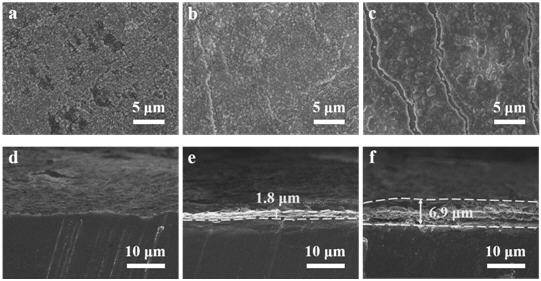

[0046] 1. The route of in-situ constructi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com