Preparation method of as-cast mixed matrix QT600-10 ductile iron

A ductile iron and matrix technology, which is applied in the field of high-performance metal materials, can solve the problems of long melt processing process, cumbersome operation, and inability to stably achieve as-cast elongation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

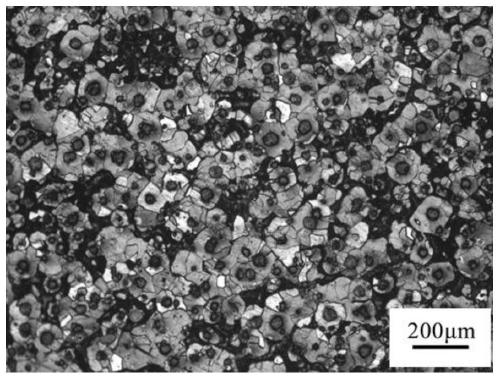

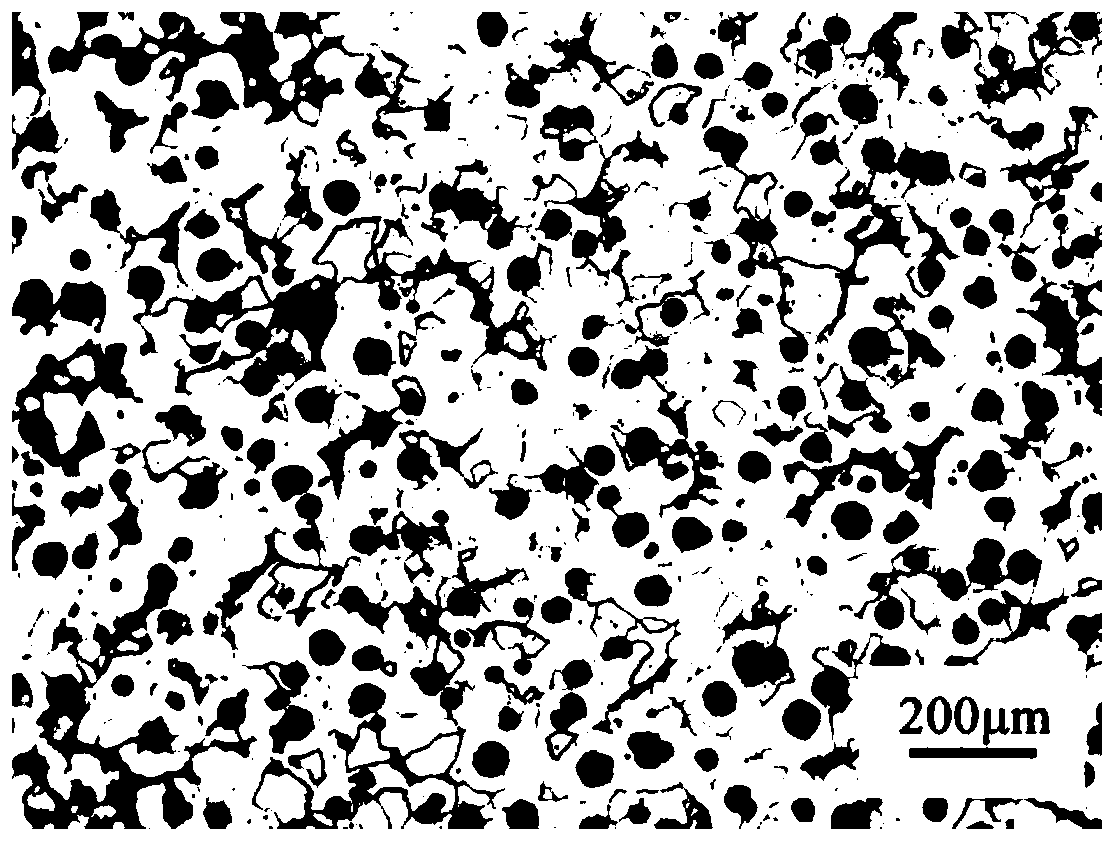

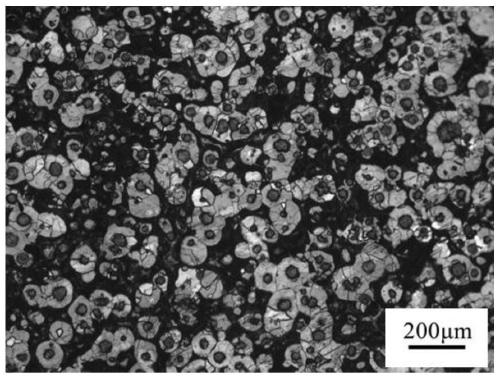

Image

Examples

Embodiment

[0031] The invention provides a method for preparing cast mixed matrix QT600-10 nodular cast iron, comprising the following steps:

[0032] S1. The input mass percentages of raw materials are as follows: pig iron: 40-60%, scrap steel: 25-40%, recycle material: 10-20%, electrolytic copper plate: 0.1-0.3%. Specifically, the pig iron used is high-purity pig iron, including the following components by mass percentage: C>4%, Si<0.5%, Mn<0.05%, P<0.02%, S<0.02%, Ti<0.02%, and the scrap steel used is Scrap steel with low manganese content includes the following components by mass percentage: C<0.04%, Si<0.007%, Mn<0.2%, P<0.008%, S<0.006%, Ti<0.001%. Both pig iron and steel scrap need to be shot blasted to treat surface rust and other impurities before use.

[0033] S2. Melting of molten iron: first add scrap steel, pig iron and recycled materials, and then add electrolytic copper plates after the scrap steel, pig iron and recycled materials are completely melted.

[0034]S3. Melt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Performance | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com