Carbon fiber composite material containing single-layer MXene nanosheet as well as preparation and application thereof

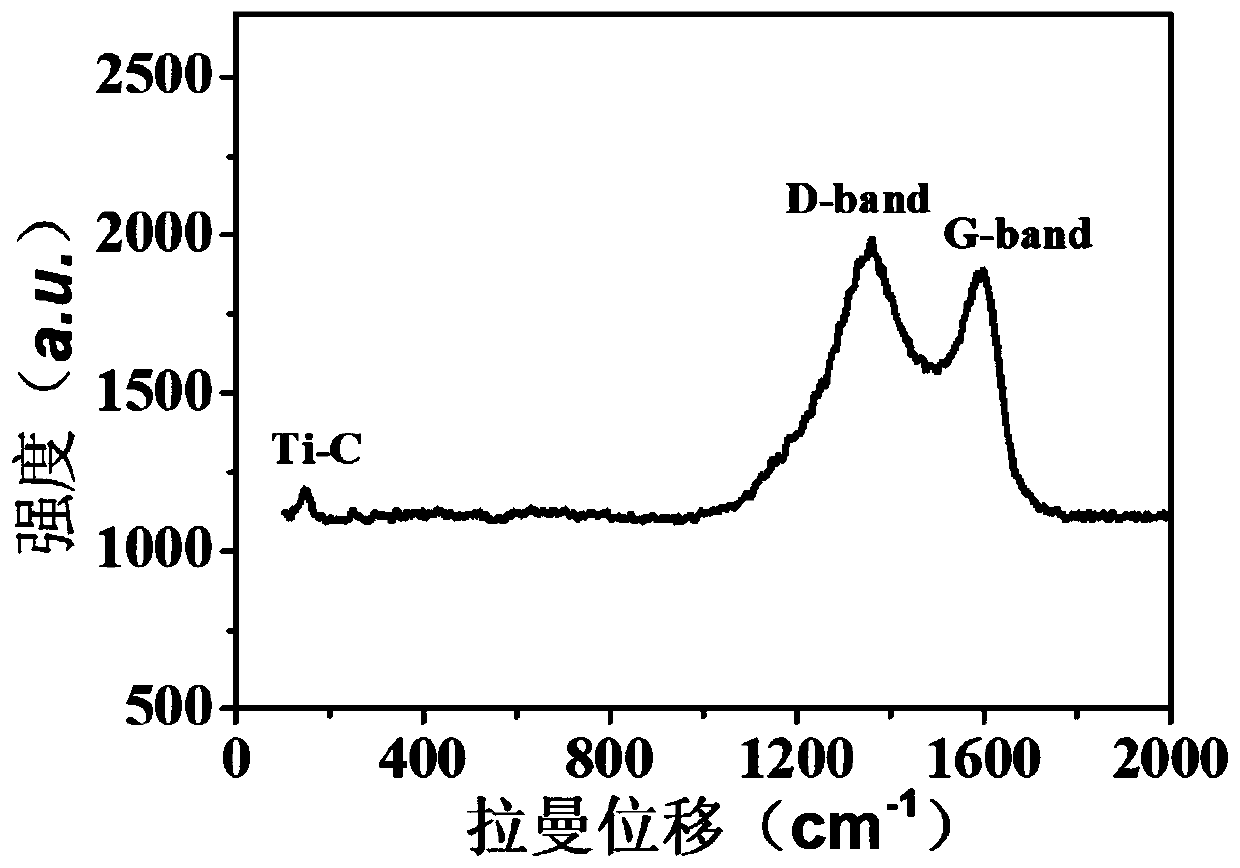

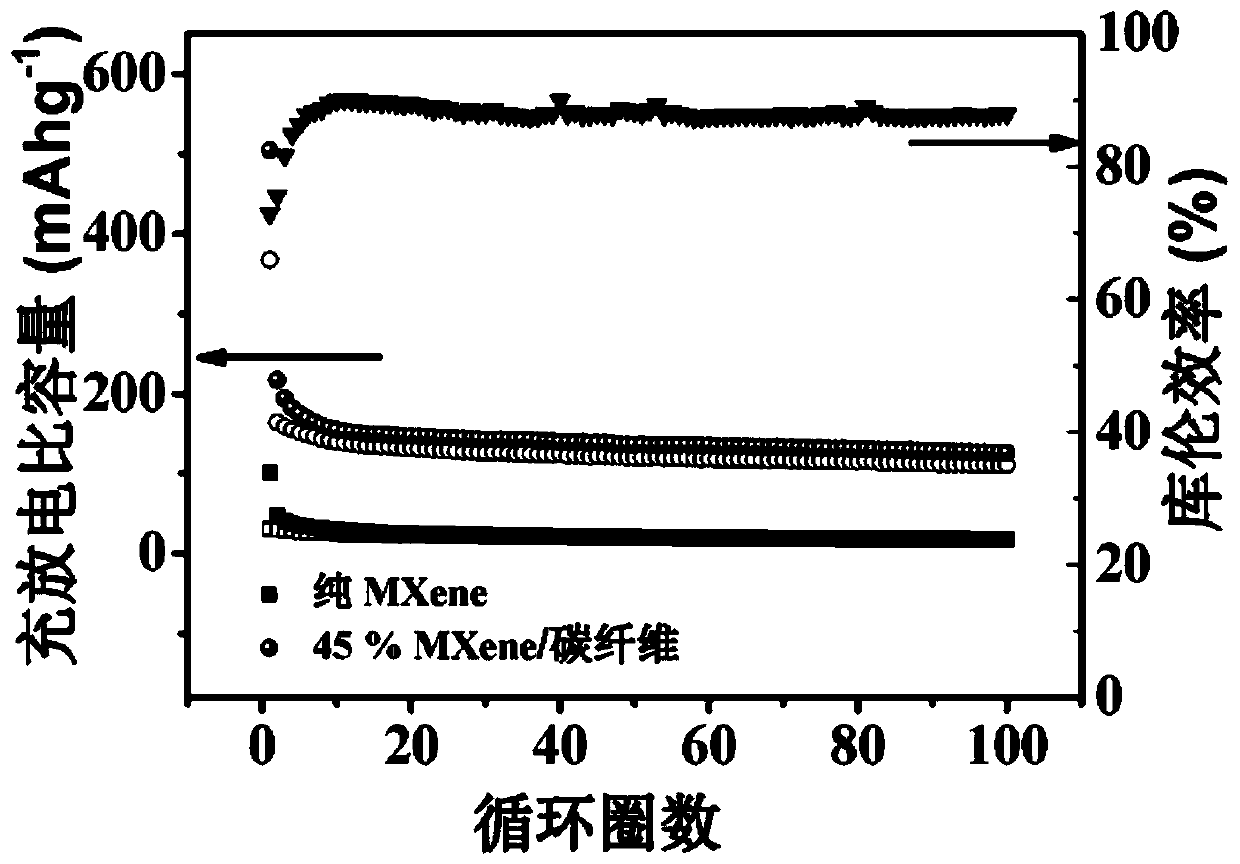

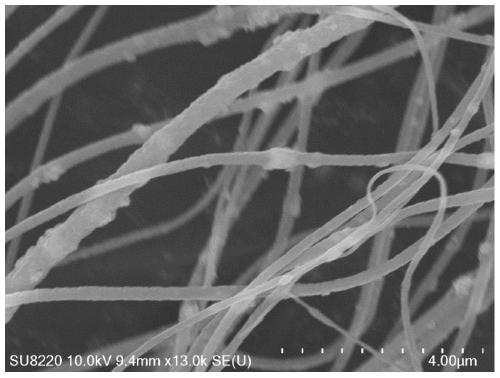

A technology of composite materials and nanosheets, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc. It can solve the problem of large sheet size, inability to inhibit the agglomeration of MXene sheets, and difficulty in embedding carbon fibers, etc. problems, to achieve the effects of inhibiting agglomeration, excellent long-term cycling, excellent rate performance and long-term cycling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Take Ti 3 SiC 2 Ti 3 SiC 2 ; Take 2g of the smaller size MAX phase obtained above and add to 20mL 9mol L -1 Hydrochloric acid and 2g LiF solution, the reaction mixture was stirred at room temperature for 36h, filtered and washed, and dried at room temperature to obtain multilayer Ti 3 C 2 T x MXene.

[0037] (2) Take 1g of the multilayer Ti obtained above 3 C 2 T x Monolayer MXene nanosheets can be obtained by ultrasonicating MXene at a power of 600 W for 2 h in an inert atmosphere.

[0038] (3) Take 0.2g of single-layer MXene nanosheets obtained in step (2), 0.84g of polyacrylonitrile, and 8.4mL of N,N-dimethylformamide in a sealed container, and after 4 hours of stirring and 4 hours of ultrasound, the composition Highly dispersed and stable electrospinning precursor solution.

[0039] (4) The prepared electrospinning precursor solution is loaded into the syringe, and the high-voltage electrospinning machine is operated at 18Kv, and the blunt needle p...

Embodiment 2

[0042] (1) Take Ta 3 AlC 2 Ta 3 AlC 2 ; Take 2g of the smaller size MAX phase obtained above and add to 15mL6mol L -1 Hydrochloric acid and 3g LiF solution, the reaction mixture was stirred at room temperature for 24h, filtered and washed, and dried at room temperature to obtain multilayer Ta 3 C 2 T x MXene.

[0043] (2) Take 1g of the multilayer Ta obtained above 3 C 2 T x MXene monolayer MXene nanosheets can be obtained by ultrasonication at 600W power for 1h in an inert atmosphere.

[0044] (3) Take 0.3g of single-layer MXene nanosheets obtained in step (2), 0.8g of polyterephthalic acid, and 10mL of N-methylpyrrolidone in a sealed container. After 6 hours of stirring and 6 hours of ultrasound, the composition is highly dispersed, Stable electrospinning precursor solution.

[0045] (4) The prepared electrospinning precursor solution is loaded into the syringe, and the high-voltage electrospinning machine is operated at 18Kv, and the blunt needle push speed is...

Embodiment 3

[0048] (1) Take Nb 4 AlC 3 20g, 200g of zirconium balls (grinding media), ball milled for 36h at a speed of 400rpm to obtain smaller Nb 4 AlC 3 ; Take 2g of the smaller size MAX phase obtained above and add to 20mL5mol L -1 Hydrochloric acid and 2.5g LiF solution, the reaction mixture was stirred at room temperature for 20h, filtered and washed, and dried at room temperature to obtain multilayer Nb 4 C 3 T x MXene.

[0049] (2) Take 1g of the multilayer Nb obtained above 4 C 3 T x Monolayer MXene nanosheets can be obtained by ultrasonicating MXene at a power of 600 W for 6 h in an inert atmosphere.

[0050] (3) Take 0.2 g of single-layer MXene nanosheets obtained in step (2), 0.15 g of polyvinyl butyral, and 10 mL of hexafluoroisopropanol in a sealed container, and after 8 hours of stirring and 8 hours of ultrasound, the composition is highly dispersed , Stable electrospinning precursor solution.

[0051] (4) The prepared electrospinning precursor solution is loa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com