Porous Nb-Ta-Ti-Si biomedical material and preparation method thereof

A technology of nb-ta-ti-si and biomedical materials, applied in the field of porous Nb-Ta-Ti-Si biomedical materials and its preparation, can solve the problems of elastic modulus stress shielding of dense metal materials, and achieve mechanical properties Proximity, promotion of bridging and occlusal, excellent biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

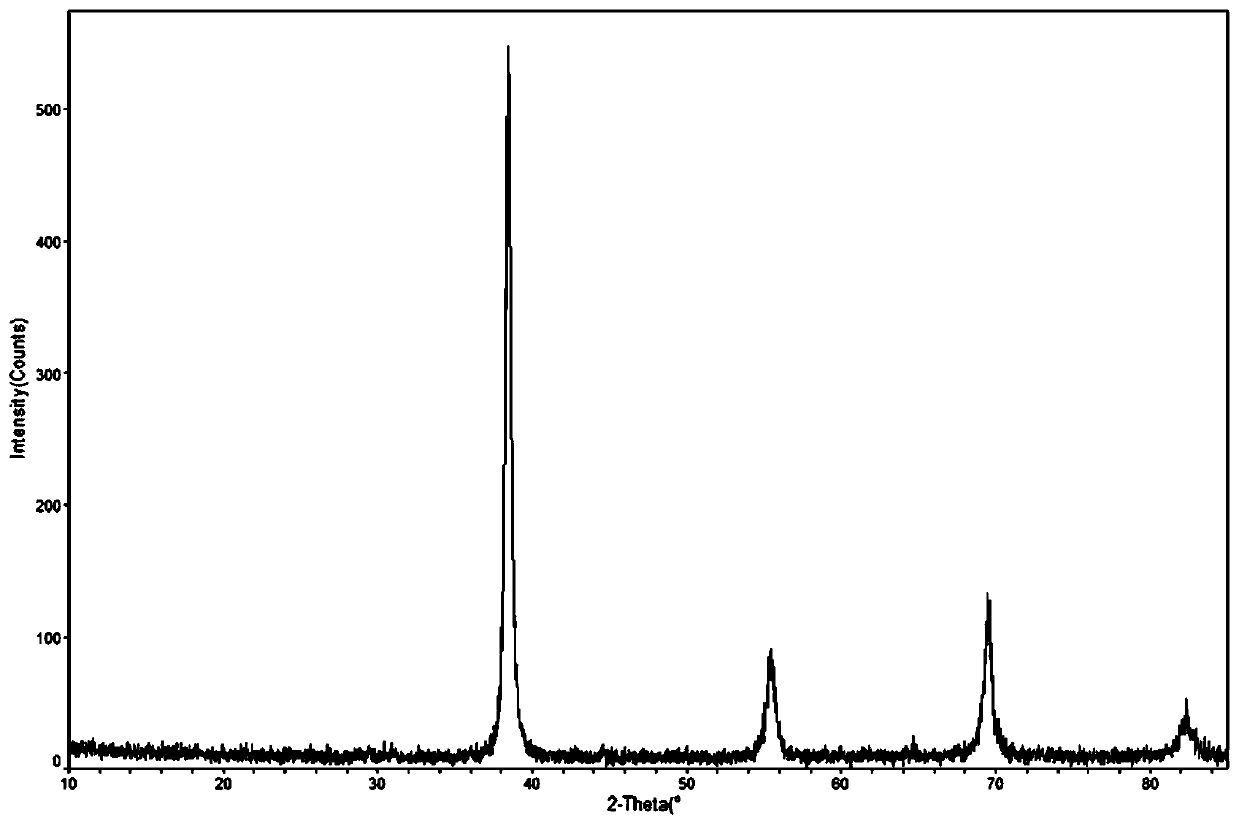

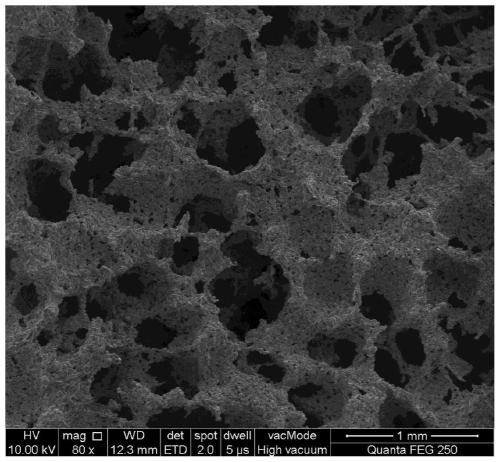

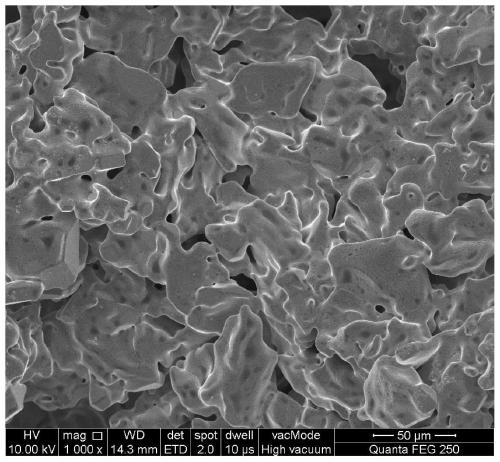

[0033] 1. Raw material formula: raw material components and mass percentages are: high-purity Ta powder 10% (purity 99.8%), Ti powder 20% (purity 99.6%), Si powder 0.1% (purity 99.6%), and the balance is Nb powder (purity 99.6%).

[0034] 2. Material preparation: Carry out high-energy ball milling, the ball-to-material ratio is 1:4, the ball milling speed is 400r. / h, and the ball milling time is 4h. During the ball milling process, anhydrous ethanol is added as the ball milling medium, and the ball mill tank is filled with argon to prevent powder oxidation. After ball milling, the powder was dried in a vacuum oven at 37° C. for 1 h to obtain a composite powder. The composite powder and the methyl cellulose aqueous solution with a mass fraction of 2% are infiltrated by ultrasonic vibration according to the mass ratio of 1:6. . The green body was vacuum dried at 37°C for 30 minutes to remove surface moisture, and then cold isostatic pressing was performed under a pressure of 2...

Embodiment 2

[0037] 1. Raw material formula: raw material components and atomic percentages are: high-purity Ta powder 10% (purity 99.8%), Ti powder 20% (purity 99.6%), Si powder 0.3% (purity 99.6%), and the balance is Nb powder (purity 99.6%).

[0038] 2. Material preparation: Carry out high-energy ball milling, the ball-to-material ratio is 1:4, the ball milling speed is 400r. / h, and the ball milling time is 4h. During the ball milling process, anhydrous ethanol is added as the ball milling medium, and the ball mill tank is filled with argon to prevent powder oxidation. After ball milling, the powder was dried in a vacuum oven at 37° C. for 1 h to obtain a composite powder. The composite powder and the methyl cellulose aqueous solution with a mass fraction of 2% are infiltrated by ultrasonic vibration according to the mass ratio of 1:6. . The green body was vacuum dried at 37°C for 30 minutes to remove surface moisture, and then cold isostatic pressing was performed under a pressure of...

Embodiment 3

[0041] 1. Raw material formula: raw material components and mass percentages are: high-purity Ta powder 10% (purity 99.8%), Ti powder 20% (purity 99.6%), Si powder 0.5% (purity 99.6%), and the balance is Nb powder (purity 99.6%).

[0042] 2. Material preparation: Carry out high-energy ball milling, the ball-to-material ratio is 1:4, the ball milling speed is 400r. / h, and the ball milling time is 4h. During the ball milling process, anhydrous ethanol is added as the ball milling medium, and the ball mill tank is filled with argon to prevent powder oxidation. After ball milling, the powder was dried in a vacuum oven at 37° C. for 1 h to obtain a composite powder. The composite powder and the methyl cellulose aqueous solution with a mass fraction of 2% are infiltrated by ultrasonic vibration according to the mass ratio of 1:6. . The green body was vacuum dried at 37°C for 30 minutes to remove surface moisture, and then cold isostatic pressing was performed under a pressure of 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com