Doped phosphorus-sulfur iodide solid electrolyte and preparation method and application thereof

A solid-state electrolyte and doping technology, which is applied in the manufacture of electrolyte batteries, phosphorus-sulfur/selenium/tellurium phosphorus compounds, electrolytes, etc., can solve problems such as the inability to meet lithium ion transmission, achieve improved ion conductivity, and easy access to raw materials , The effect of simple raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

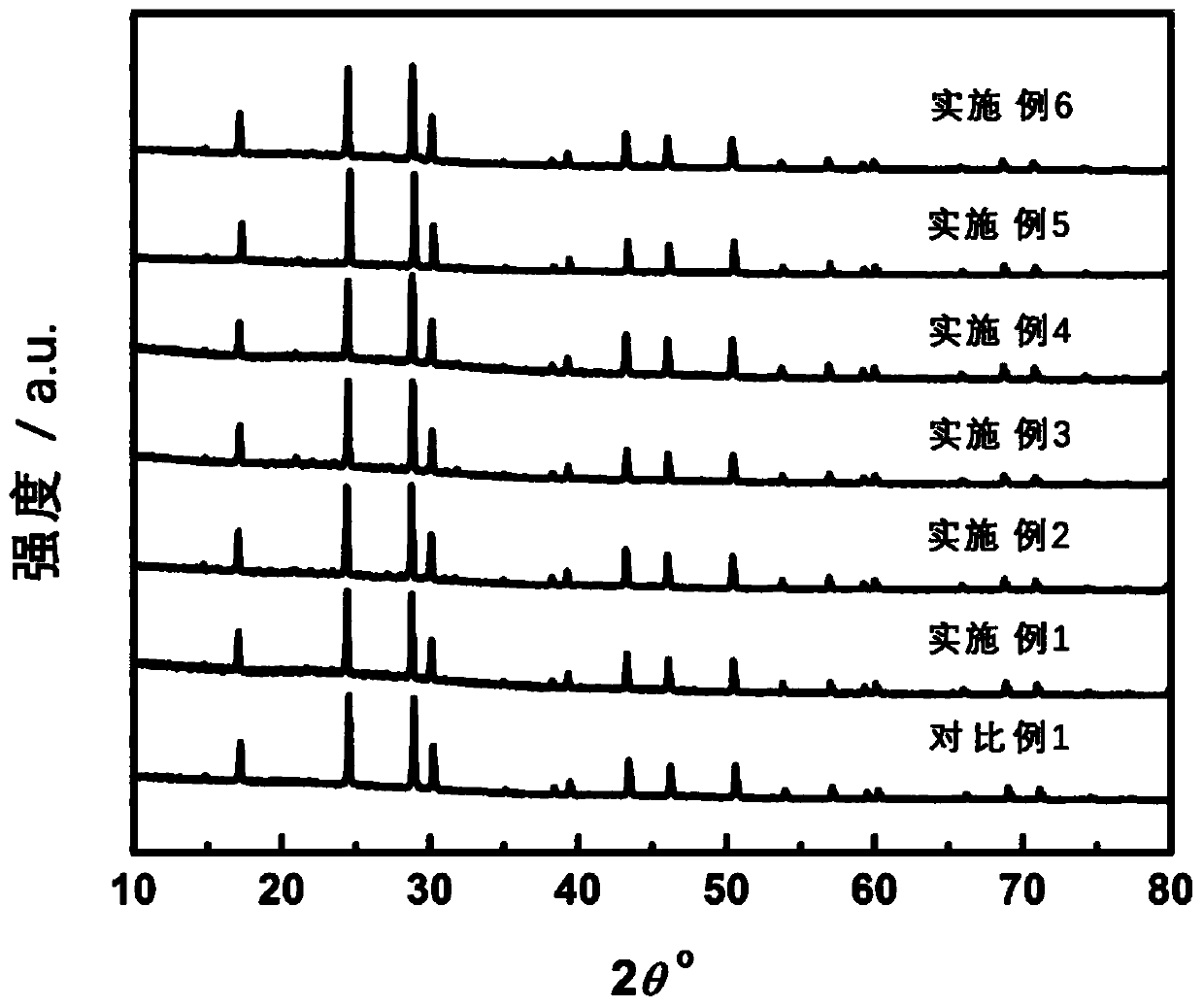

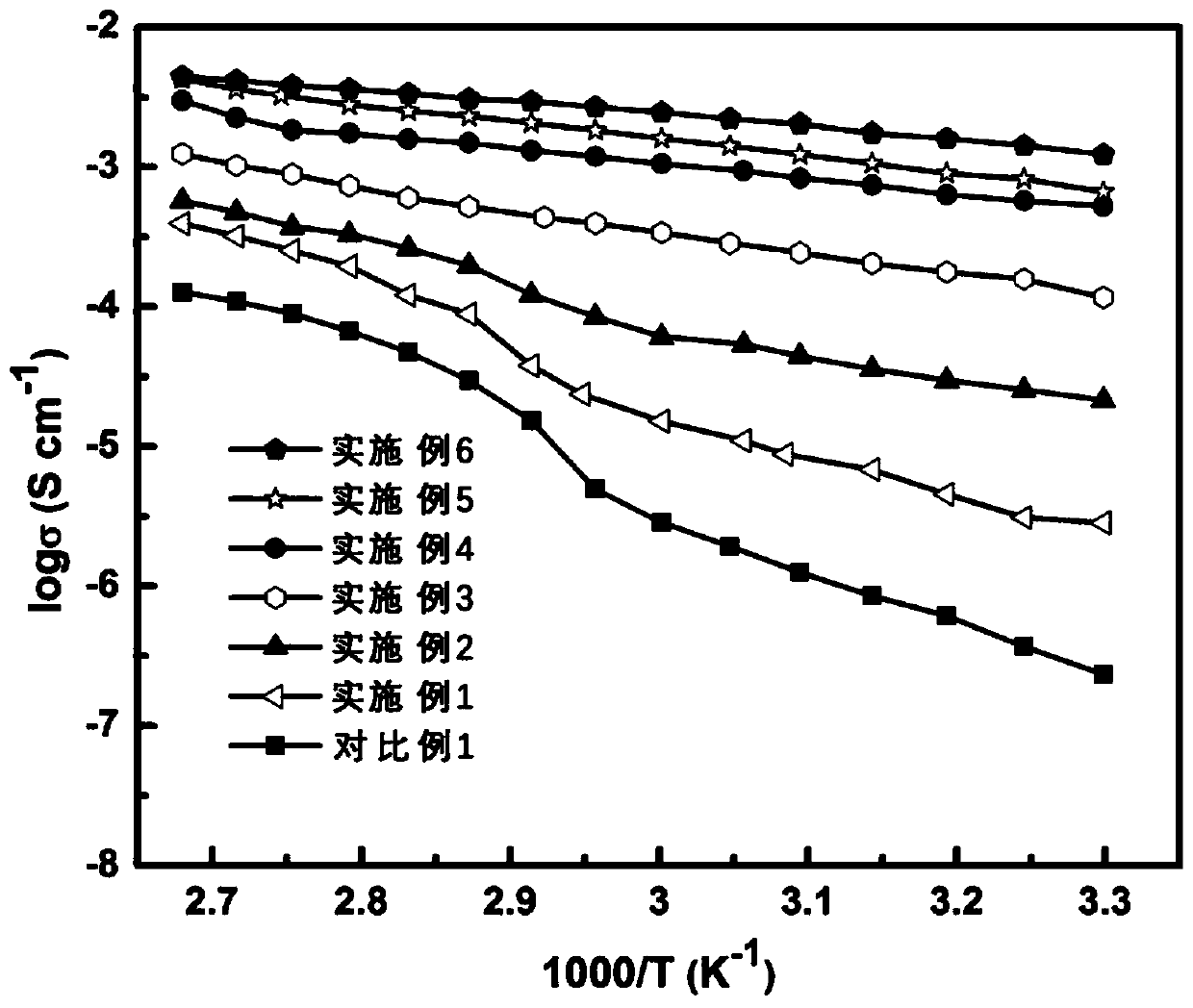

Embodiment 1

[0064] This embodiment provides a method for preparing a doped phosphorus-sulfur-iodide solid-state electrolyte, comprising the following steps:

[0065] (1) Weigh 0.478g, 0.500g, 0.670g, 0.092g and 0.048g of lithium sulfide, phosphorus pentasulfide, lithium iodide, tungsten powder and sulfur powder according to the molar ratio of 2.45:0.45:1:0.1:0.3 respectively, Ball milling in a ball mill tank protected by an air atmosphere, using 20 zirconia ball milling beads with a diameter of 12 mm, the ball milling speed is 350 rpm, the ball milling time is 18 hours, and the ball mill is cooled for 10 minutes every 30 minutes to obtain a solid electrolyte precursor;

[0066](2) Under an argon atmosphere, transfer the solid electrolyte precursor from the ball mill tank to a quartz tube, and then put it into a tube furnace for sintering. The heating rate is 2°C / min, and the sintering temperature is 550°C. After holding for 5 hours After natural cooling, it is ground into powder to obtain...

Embodiment 2

[0069] This embodiment provides a method for preparing a doped phosphorus-sulfur-iodide solid-state electrolyte, comprising the following steps:

[0070] (1) Weigh 0.468g, 50.444g, 0.670g, 0.184g and 0.096g of lithium sulfide, phosphorus pentasulfide, lithium iodide, tungsten powder and sulfur powder according to the molar ratio of 2.4:0.4:1:0.2:0.6 respectively, Ball milling in a ball mill tank protected by an air atmosphere, using 20 zirconia ball milling beads with a diameter of 12 mm, the ball milling speed is 400 rpm, the ball milling time is 15 hours, and the ball mill is cooled for 6 minutes every 35 minutes to obtain a solid electrolyte precursor;

[0071] (2) Under an argon atmosphere, transfer the solid electrolyte precursor from the ball mill tank to a quartz tube, and then put it into a tube furnace for sintering. The heating rate is 1°C / min, and the sintering temperature is 550°C. After holding for 5 hours After natural cooling, it is ground into powder to obtain ...

Embodiment 3

[0074] This embodiment provides a method for preparing a doped phosphorus-sulfur-iodide solid-state electrolyte, comprising the following steps:

[0075] (1) Lithium sulfide, phosphorus pentasulfide, lithium iodide, tungsten disulfide and sulfur powder are respectively weighed 0.458g, 50.3885g, 0.670g, 20.372g and 0.048g according to the molar ratio of 2.35:0.35:1:0.3:0.9, in Ball milling in a ball mill tank protected by an argon atmosphere, using 18 zirconia ball milling beads with a diameter of 12mm, the ball milling speed is 350rpm, the ball milling time is 18h, and the ball mill is cooled for 10 minutes every 30 minutes to obtain a solid electrolyte precursor;

[0076] (2) Under an argon atmosphere, transfer the solid electrolyte precursor from the ball mill tank to a quartz tube, and then put it into a tube furnace for sintering. The heating rate is 2°C / min, and the sintering temperature is 550°C. After holding for 2 hours After natural cooling, it is ground into powder t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com