Novel method for comprehensively recovering cobalt, nickel, manganese and lithium elements from ternary battery waste

A ternary battery, cobalt-nickel-manganese technology, applied in the field of battery waste recycling, can solve the problem of high recycling costs, achieve the effects of reducing production costs, simple process, and reducing material consumption and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

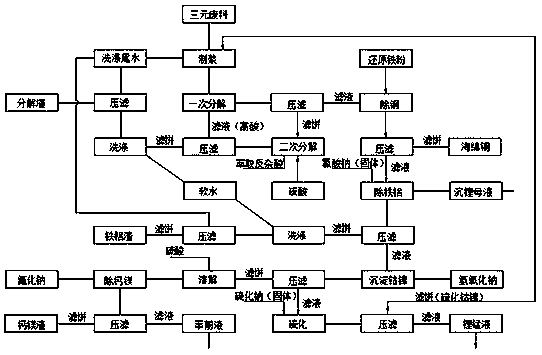

[0023] Implementation method: A new method for comprehensively recovering cobalt, nickel, manganese, and lithium elements from ternary battery waste is carried out as follows:

[0024] a. The waste ternary battery material powder obtained by dismantling the waste ternary battery is subjected to acid leaching to remove copper, iron and aluminum to obtain an impurity removal solution.

[0025] b. Adjust the pH value of the impurity removal solution to 5.5-6.5 with sodium hydroxide, precipitate a mixture of cobalt hydroxide and nickel hydroxide, filter, wash, and process the filter cake and filtrate separately.

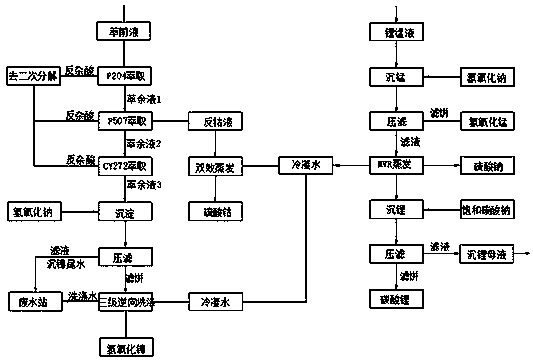

[0026] c. The filter cake is a mixture of cobalt hydroxide and nickel hydroxide. After being dissolved in sulfuric acid, adjust the pH to about 5.0-6.0, add fluoride to the solution to remove calcium and magnesium ions, filter and wash, and the filtrate enters the P204 extraction process. Deeply remove impurities, and the extraction residue enters the P507 extraction pro...

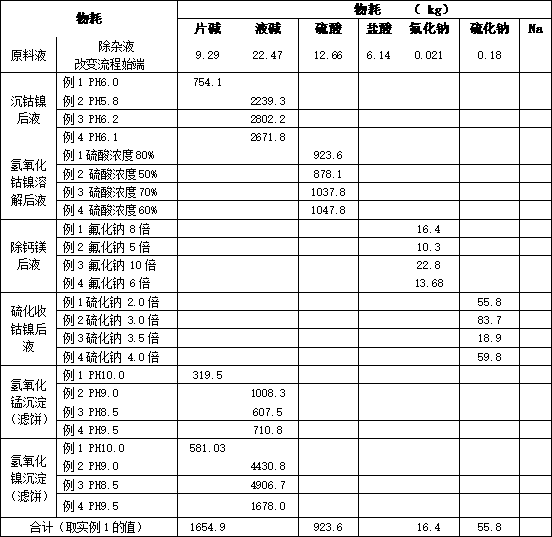

Embodiment 1

[0038] Embodiment 1: the new method of comprehensive recovery cobalt nickel manganese lithium element from ternary battery waste material, take the following steps:

[0039] a. Waste ternary battery material powder obtained by dismantling waste ternary batteries, after acid leaching, copper removal, iron and aluminum removal, etc., to obtain impurity removal liquid.

[0040] b. Adjust the pH value of the impurity removal solution to 6.0 with 98% solid sodium hydroxide to precipitate a mixture of cobalt hydroxide and nickel hydroxide, filter, wash, and process the filter cake and filtrate separately.

[0041] C. Slowly add the cobalt hydroxide and nickel hydroxide mixture into 80% sulfuric acid solution, and adjust the pH to 5.5 with the cobalt hydroxide and nickel hydroxide mixture; add physical fluorine according to 8 times the total amount of calcium and magnesium ions in the solution ammonium chloride, react for 60 minutes, filter and wash; the filter cake is calcium and ma...

Embodiment 2

[0046] Embodiment 2: the new method of cobalt-nickel-manganese-lithium comprehensive recovery from ternary battery waste material, take the following steps:

[0047] a. Waste ternary battery material powder obtained by dismantling waste ternary batteries, after acid leaching, copper removal, iron and aluminum removal, etc., to obtain impurity removal liquid.

[0048] b. Adjust the pH value of the impurity removal solution to 5.8 with 32% sodium hydroxide solution to precipitate a mixture of cobalt hydroxide and nickel hydroxide, filter, wash, and process the filter cake and filtrate separately.

[0049] C. Slowly add the mixture of cobalt hydroxide and nickel hydroxide to 50% sulfuric acid solution, and adjust the pH to 6.0 with the mixture of cobalt hydroxide and nickel hydroxide; add fluorine in kind according to 5 times the total amount of calcium and magnesium ions in the solution Potassium, react for 50 minutes, filter and wash; the filter cake is calcium magnesium slag, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com