Porous diaphragm, preparation method thereof and lithium ion battery

A technology of porous diaphragm and pore size, applied in the field of porous diaphragm and its preparation method and lithium ion battery, can solve the problems of electrospinning being susceptible to vibration and electric field interference, poor strength of spinning film, short circuit of battery, etc., and achieve high consistency , The effect of low battery internal resistance and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] A second aspect of the present invention provides a method for preparing a porous membrane, the method comprising:

[0048] (1) Organic solvent and crystalline polyimide are mixed, dissolved, and defoamed to obtain a casting solution;

[0049] (2) Using the casting solution to prepare a diaphragm to obtain a diaphragm;

[0050] (3) The separator is placed for 5-60 minutes under constant temperature and humidity conditions with a humidity of 30%-90%RH and a temperature of 10-70°C to obtain a porous separator.

[0051] In the above preparation method, the volatilization of the organic solvent will take away the heat, reducing the temperature of the organic solvent in the diaphragm, and the temperature difference between the ambient temperature and the temperature of the organic solvent will cause condensation of water droplets in the humidity environment, and the condensed water droplets will penetrate Through the organic solvent, the immiscibility between water and crys...

Embodiment 1

[0068] Prepare an N-methylpyrrolidone solution with a mass fraction of 25% ether anhydride polyimide. After stirring until completely dissolved, let it stand for a period of time, and wait for the casting solution to be completely degassed before use.

[0069] Apply the casting solution to the glass plate with a scraper to prepare the diaphragm, place the glass plate with the diaphragm in a constant temperature and humidity box, set the temperature at 50°C, the humidity at 60% RH, and the time for 30 minutes. Take it out when the volatilization is complete and form a film, and make a porous separator C1.

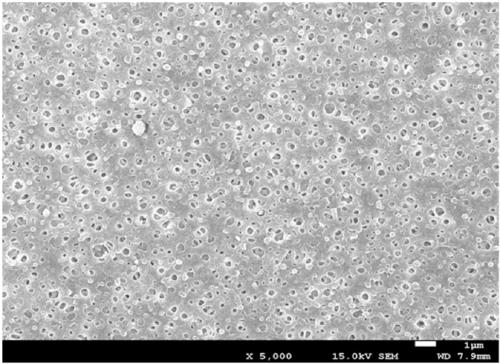

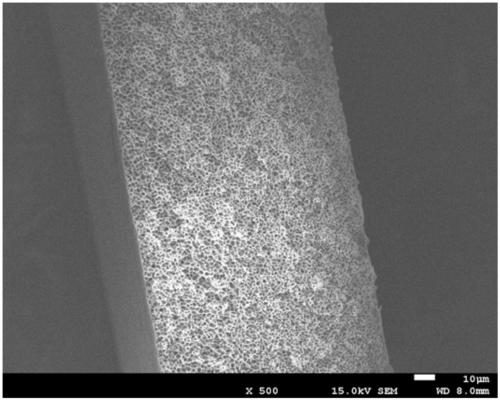

[0070] The morphology of porous separator C1 was measured by field emission scanning electron microscope JEOL-7600F as follows: figure 1 with figure 2 As shown, compared with the scale on the figure, it can be seen that the pore size is 100-500 nm and the thickness is 50 μm.

[0071] And further test the air permeability, tensile strength, heat shrinkage resistance, etc....

Embodiment 2

[0073] Prepare a chloroform solution with a mass fraction of 10% ketone anhydride polyimide. After stirring until completely dissolved, let it stand for a period of time, and wait for the casting solution to be completely degassed before use.

[0074] The casting liquid is poured into a specific mold by pouring method, and placed in a constant temperature and humidity box with a set temperature of 40°C, a humidity of 60% RH, and a time of 30 minutes. Take it out when the solvent is completely evaporated and the film is formed, and the porous diaphragm is made. C2.

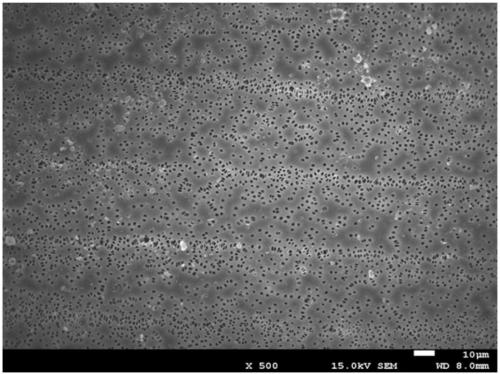

[0075] The morphology of porous separator C2 was measured by field emission scanning electron microscope JEOL-7600F as image 3 with Figure 4 As shown, compared with the scale on the figure, it can be seen that the pore size is 100-200 nm and the thickness is 20 μm.

[0076] And further test the air permeability, tensile strength, heat shrinkage resistance, etc. of the separator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com