Process and equipment for purifying paraphthaloyl chloride

A technology for terephthaloyl chloride and crude terephthaloyl chloride, which is applied in chemical instruments and methods, preparation of organic compounds, carboxylate preparation, etc., can solve the problems of aggravated separation difficulty, high boiling point of products, and difficulty in off-line control and other problems, to achieve the effect of high system operation safety factor, mild process operation conditions, and reduced steam unit consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A process method for purifying terephthaloyl chloride specifically includes the following steps:

[0050] (1) Preparation of terephthaloyl chloride

[0051] Under the LED light source (the wavelength range of the LED light source is 380-480nm), p-xylene is injected with excess chlorine to react to obtain 1,4-bis(trichloromethyl)benzene solution, and then terephthalic acid is added. The reaction is carried out under the action of a solid catalyst until no hydrogen chloride gas is released to prepare crude terephthaloyl chloride.

[0052] Among them: the solid catalyst is anhydrous ZnCl 2 The amount of solid catalyst used is 0.1% of the mass of terephthalic acid; the mass ratio of 1,4-bis(trichloromethyl)benzene to terephthalic acid is 1:0.51.

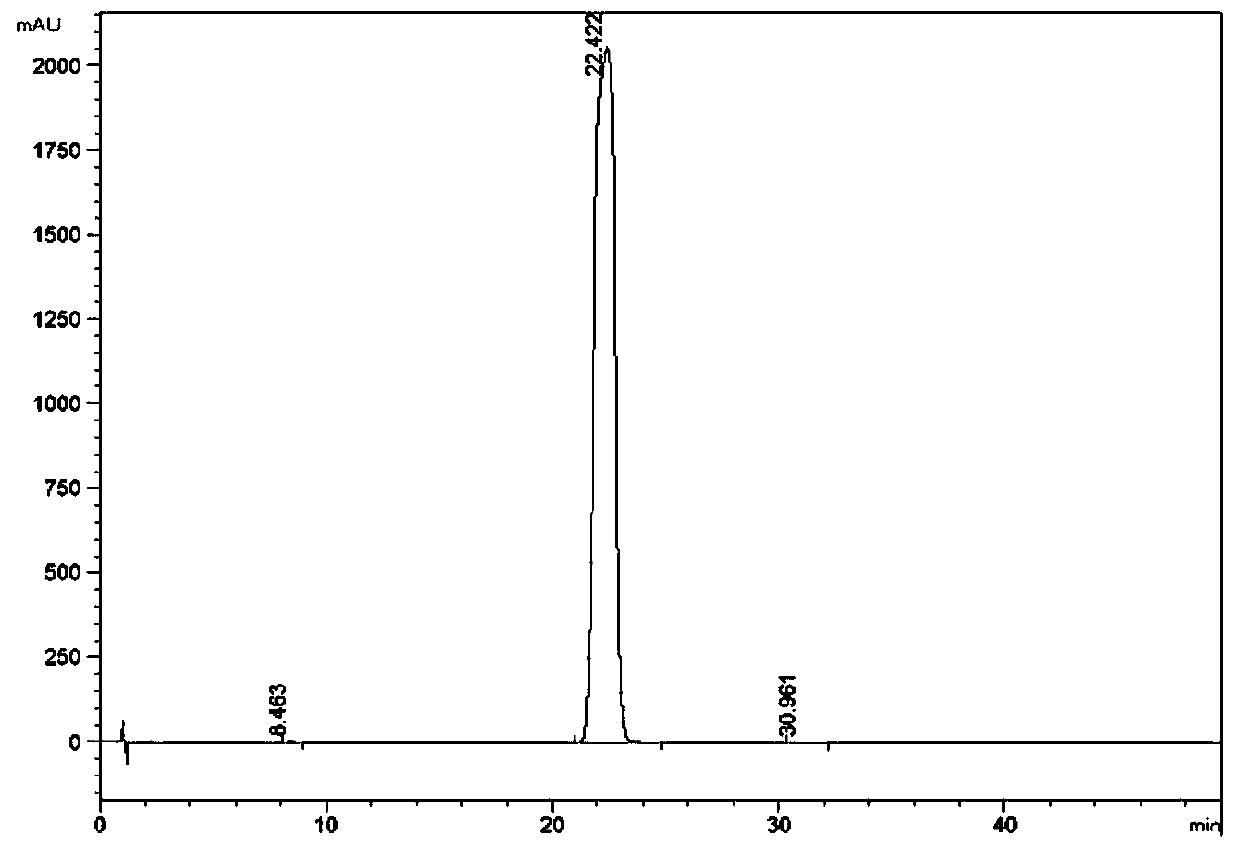

[0053] The composition of the prepared crude terephthaloyl chloride is as follows:

[0054] In terms of mass fraction, it consists of 96.5% terephthaloyl chloride, 0.5% terephthalic acid, 2.7% 1,4-bis(trichloromethyl)benzene and 0.3% solid...

Embodiment 2

[0078] A process method for purifying terephthaloyl chloride specifically includes the following steps:

[0079] (1) Preparation of terephthaloyl chloride

[0080] Under the LED light source (the wavelength range of the LED light source is 380-480nm), p-xylene is injected with excess chlorine to react to obtain 1,4-bis(trichloromethyl)benzene solution, and then terephthalic acid is added. The reaction is carried out under the action of a solid catalyst until no hydrogen chloride gas is released to prepare crude terephthaloyl chloride.

[0081] Among them: the solid catalyst is anhydrous A1C1 3 The amount of solid catalyst used is 0.3% of the mass of terephthalic acid; the mass ratio of 1,4-bis(trichloromethyl)benzene to terephthalic acid is 1:0.57.

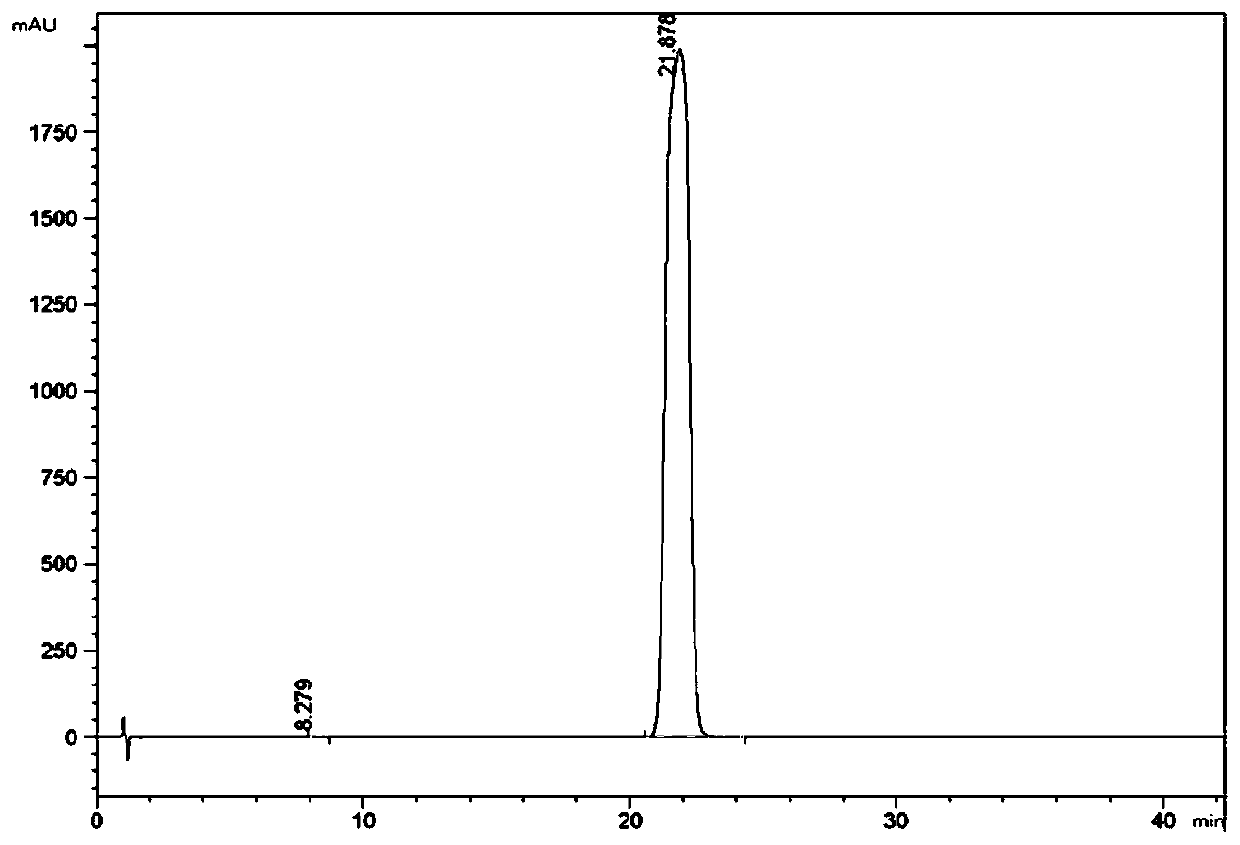

[0082] The composition of the prepared crude terephthaloyl chloride is as follows:

[0083] In terms of mass fraction, it consists of 94% terephthaloyl chloride, 2.5% terephthalic acid, 3.2% 1,4-bis(trichloromethyl)benzene and 0.3% solid c...

Embodiment 3

[0106] A process method for purifying terephthaloyl chloride specifically includes the following steps:

[0107] (1) Preparation of terephthaloyl chloride

[0108] Under the LED light source (the wavelength range of the LED light source is 380-480nm), p-xylene is injected with excess chlorine to react to obtain 1,4-bis(trichloromethyl)benzene solution, and then terephthalic acid is added. The reaction is carried out under the action of a solid catalyst until no hydrogen chloride gas is released to prepare crude terephthaloyl chloride.

[0109] Among them: the solid catalyst is anhydrous FeC13; the usage amount of the solid catalyst is 0.5% of the mass of terephthalic acid; the mass ratio of 1,4-bis(trichloromethyl)benzene to terephthalic acid is 1:0.54.

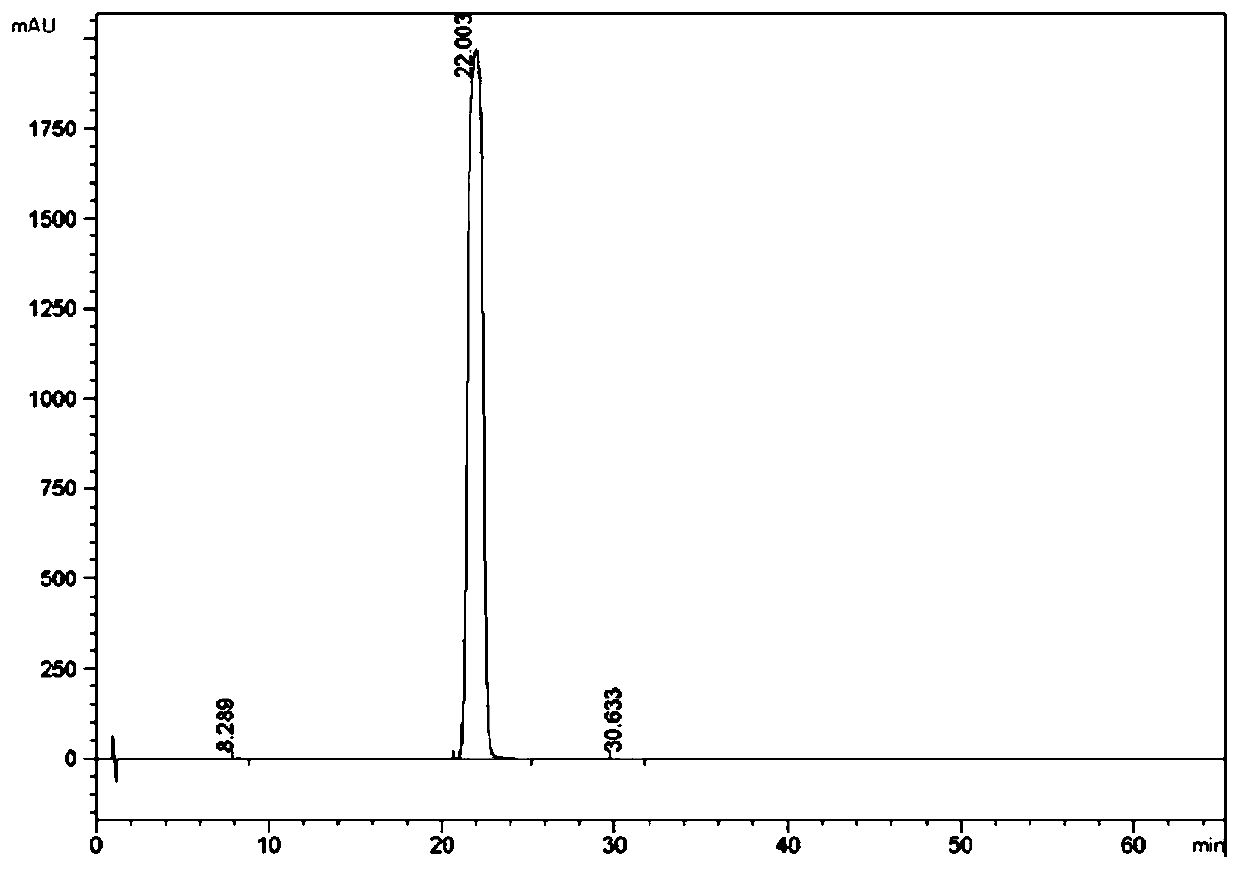

[0110] The composition of the prepared crude terephthaloyl chloride is as follows:

[0111] In terms of mass fraction, it consists of 95.5% terephthaloyl chloride, 1.5% terephthalic acid, 2.8% 1,4-bis(trichloromethyl)benzene and 0.2% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com