Reactive flame retardant as well as preparation method and application thereof

A reactive flame retardant and solvent technology, used in the field of flame retardants, can solve problems such as fire hazards, and achieve the effects of convenient post-processing, mild conditions and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

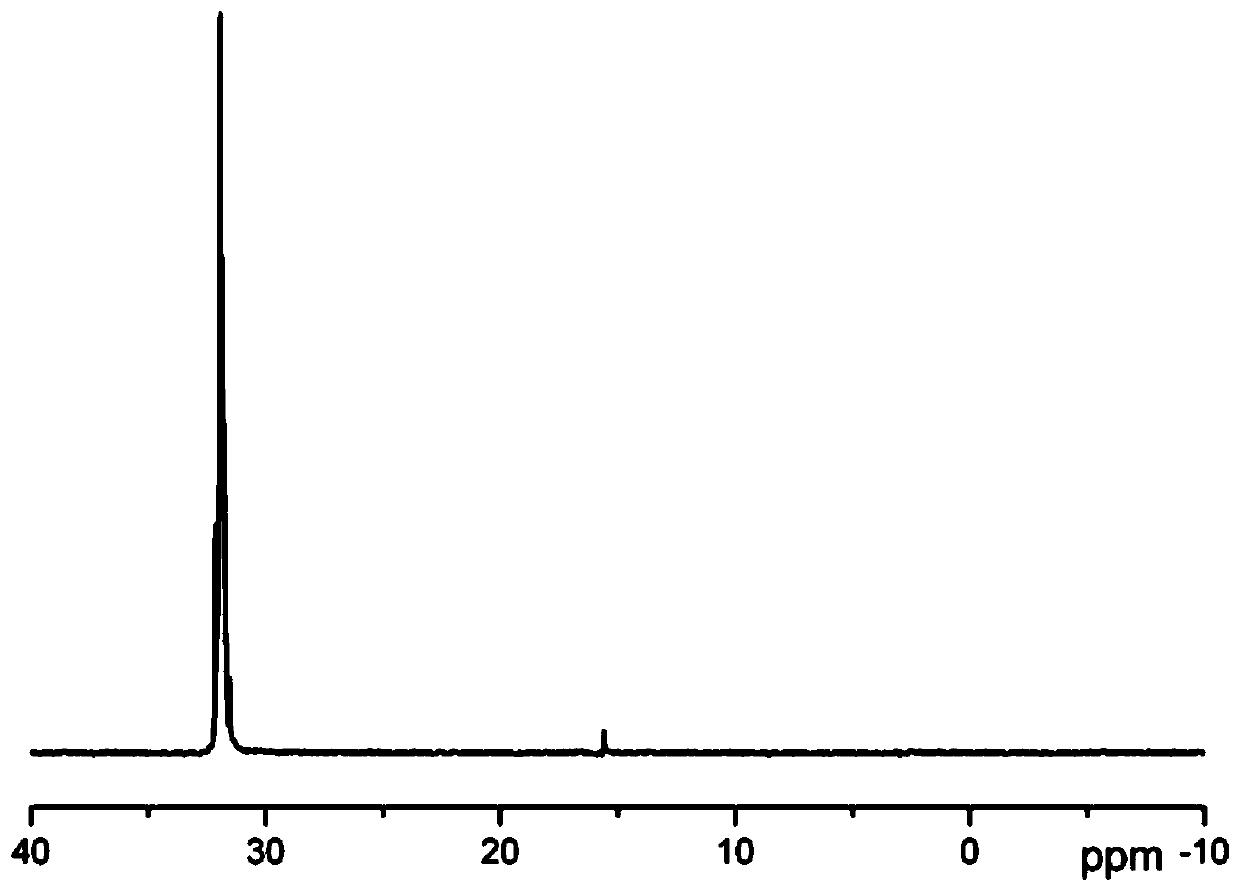

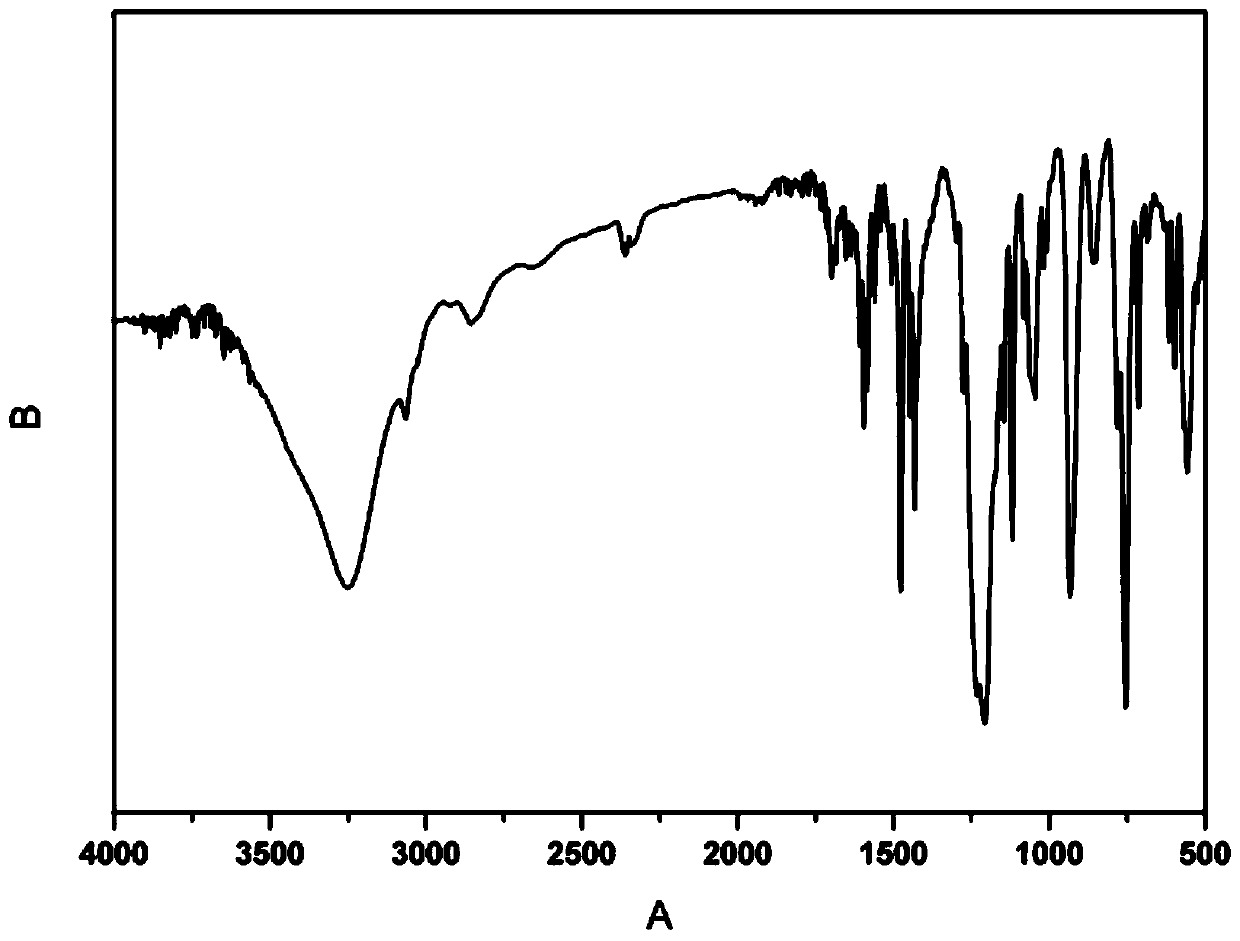

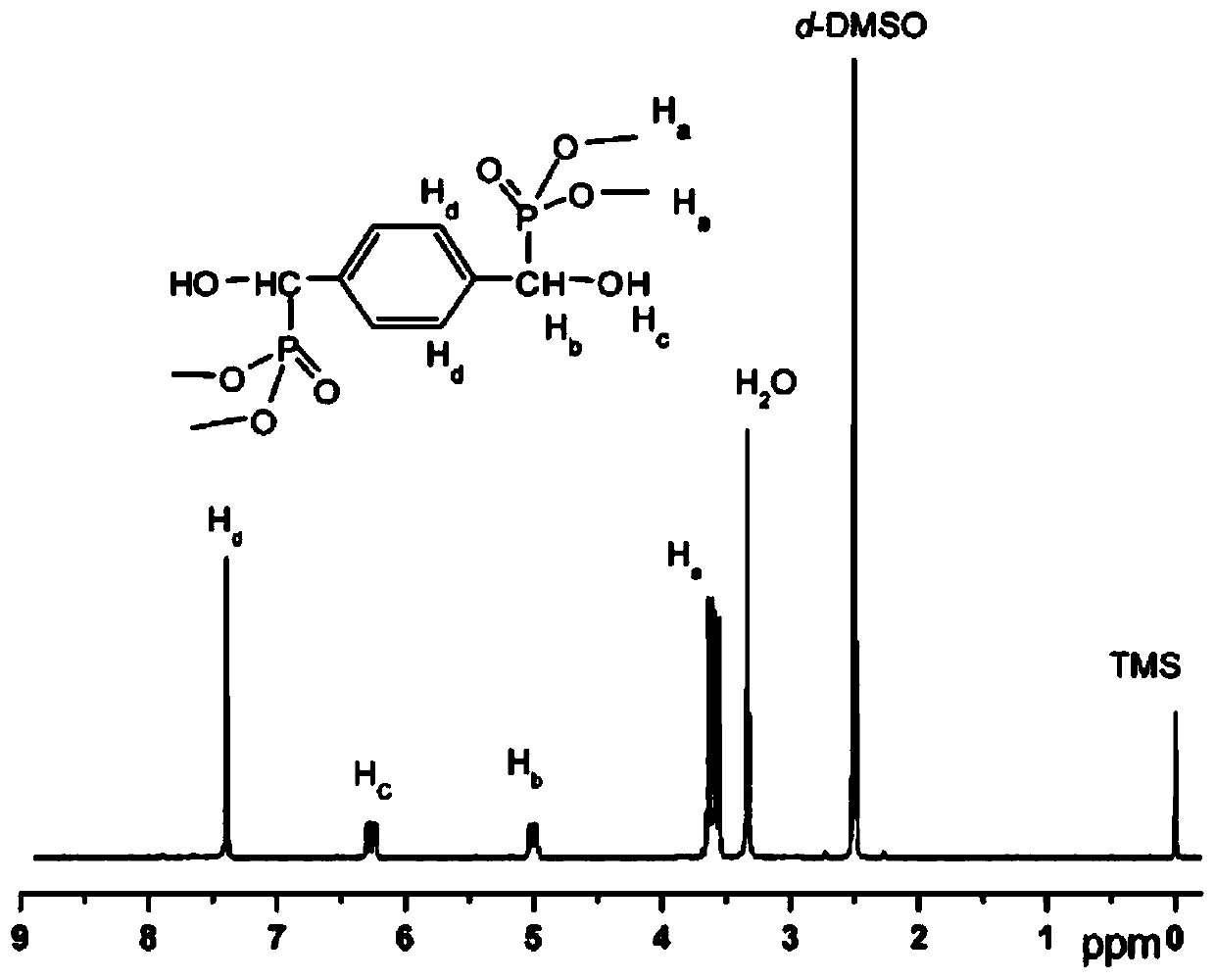

[0048] Add 25mL of tetrahydrofuran as a solvent to a 100mL three-neck flask equipped with a reflux condenser, a thermometer, and a stirring rod, and then add 3mL of xylene, heat to 80°C and stir evenly, then add 16.4g of TDCA (0.1mol), 37.2g of DMMP (0.3mol), in N 2 The reaction was maintained at 80°C for 5h under the atmosphere. After the reaction, the mixture was filtered, washed and dried to obtain the flame retardant as a white solid with a yield of 91%. The nuclear magnetic phosphorus spectrum of the obtained product is as follows figure 1 As shown, the infrared spectrum is shown in figure 2 As shown, the H NMR spectrum is shown as image 3 shown. Observation of the above drawings can prove that the target product has the structure shown in the above formula (I).

[0049]Mix 22 parts of the flame retardant prepared in this example with 78 parts of EP (product model 4926), and make a composite material by twin-screw extruder at 190°C.

[0050] Referring to the Ameri...

Embodiment 2

[0060] Add 62.5mL of acetonitrile as a solvent to a 250mL three-necked flask equipped with a reflux condenser, a thermometer and a stirring rod, then add 7.5mL of xylene, heat to 80°C and stir evenly, then add 41g of TDCA (0.25mol), 93g of DMMP (0.75mol), in N 2 The reaction was maintained at 80°C for 5h under the atmosphere. After the reaction, the mixture was filtered, washed and dried to obtain the flame retardant as a white solid with a yield of 79%.

[0061] Mix 22 parts of the flame retardant obtained in this example with 78 parts of EP (product model 4926), and make a composite material by twin-screw extruder at 190°C.

[0062] The above composite material is made into UL94 1.6mm standard sample in an injection molding machine, and the standard test is carried out on a horizontal and vertical combustion instrument and an oxygen index tester. After testing, the flame retardant grade of the sample is: UL94 1.6mm V-0 grade, oxygen index 30.

[0063] The above-mentioned ...

Embodiment 3

[0066] Add 250ml tetrahydrofuran as a solvent to a 1000mL three-necked flask equipped with a reflux condenser, a thermometer, and a stirring rod, then add 30mL of trimethylbenzene, heat to 80°C and stir evenly, then add 164g (1mol) of TDCA and 372gDMMP (3mol), in N 2 The reaction was maintained at 80°C for 5h under the atmosphere. After the reaction, the mixture was filtered, washed and dried to obtain a white solid with a yield of 84%.

[0067] Mix 22 parts of the flame retardant obtained in this example with 78 parts of EP (product model 4926), and make a composite material by twin-screw extruder at 190°C.

[0068] The above composite material is made into UL94 1.6mm standard sample in an injection molding machine, and the standard test is carried out on a horizontal and vertical combustion instrument and an oxygen index tester. After testing, the flame retardant grade of the sample is: UL94 1.6mm V-0 grade, oxygen index 30.

[0069] The above-mentioned composite material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com