Modification method of phase change energy storage material

A phase-change energy storage material and phase-change material technology, applied in the field of modification of phase-change energy storage materials, can solve problems such as small equivalent thermal conductivity, settlement, wear and blockage of heat exchange equipment, and improve energy storage efficiency , the effect of low system density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

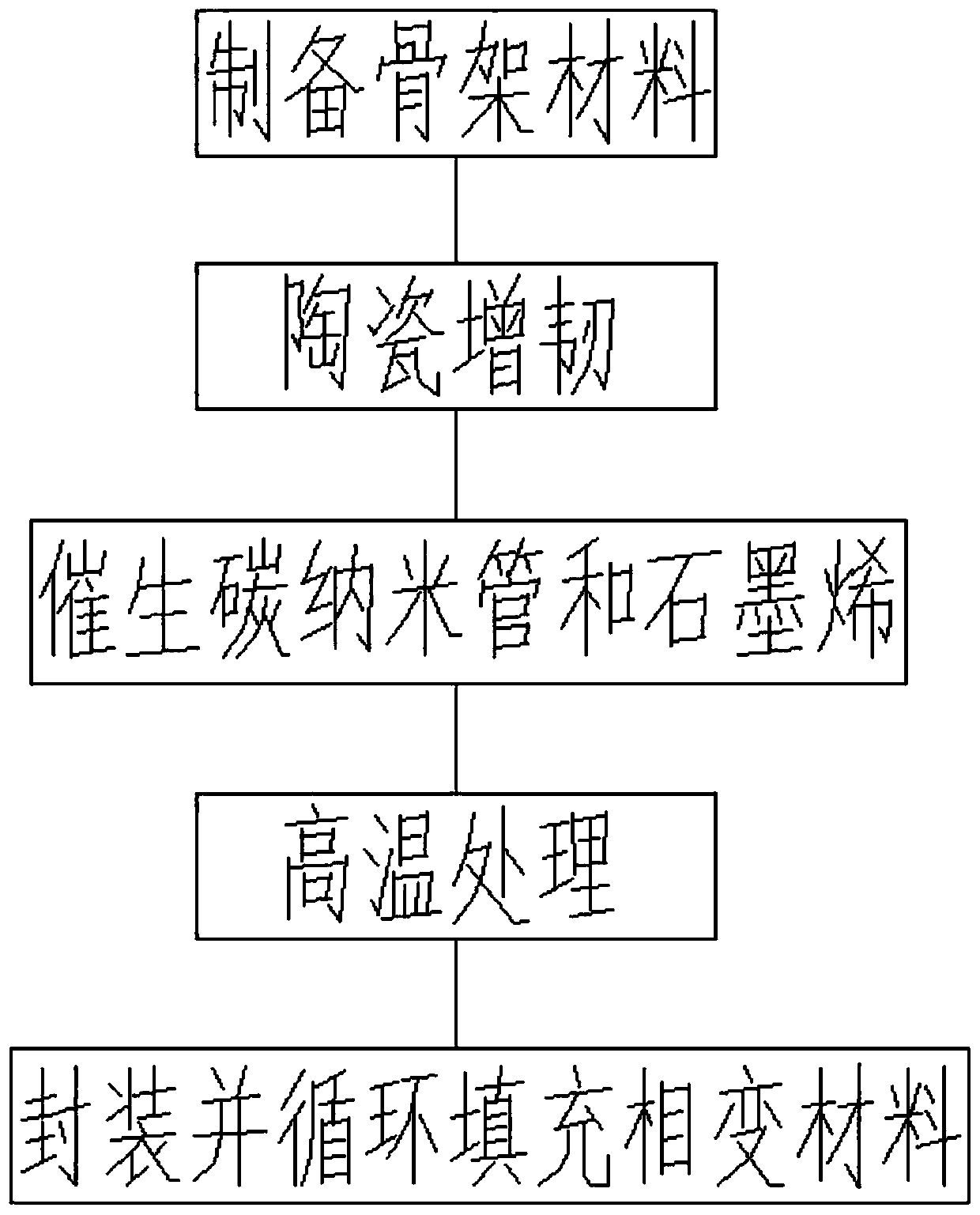

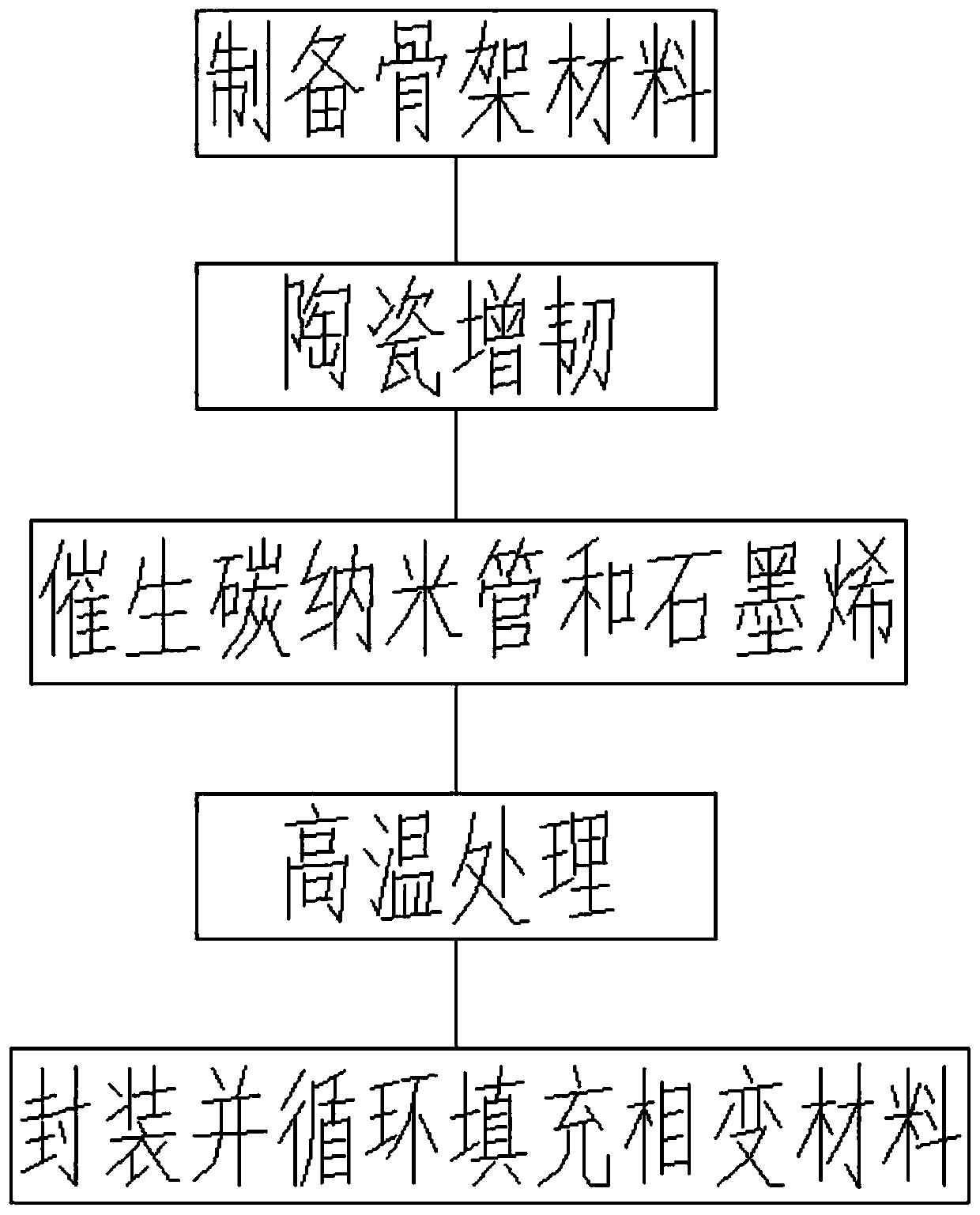

[0022] Such as figure 1 as shown, figure 1 It is a flowchart of the modification method of the phase change energy storage material; the modification method of the phase change energy storage material in the present invention includes the following steps;

[0023] S1, preparation of framework material:

[0024] The micron-scale high thermal conductivity carbon fiber is uniformly dispersed in the mesophase pitch and then foamed and carbonized to form the skeleton material. The mass fraction of the micron-scale high thermal conductivity carbon fiber in the skeleton material is about 3% to 6%, and the pressure in the foaming process is 4MPa-8MPa;

[0025] S2, performing ceramic toughening on the framework material:

[0026] Deposit SiC (silicon carbide) ceramic material in CVD (Chemical Vapor Deposition) equipment for the framework material, and perform ceramic toughening on the framework material;

[0027] S3, catalyzing the growth of CNTs (carbon nanotubes) and graphene on ...

Embodiment 2

[0036] The internal cavity of the metal box of the phase change system is 80mm long, 60mm wide, and 20mm thick. In the process of modifying the paraffin phase change material, the density of the paraffin phase change material used is about 0.9g / cm 3 .

[0037] S1, first prepare the skeleton material, 3% mass content of high thermal conductivity carbon fiber and 97% mass content of mesophase pitch through 4MPa pressure, 450 ° C foaming process, 900 ° C carbonization process, prepared a density of 0.31 g / cm 3 of the skeleton material. The skeleton material is processed into a near-net size state of 85mmX65mmX25mm.

[0038] S2, deposit SiC material in special CVD (Chemical Vapor Deposition) equipment, perform ceramic toughening on the framework material, the process time is about 6 hours, and the density of the framework material is increased to 0.36g / cm 3 .

[0039] S3, adding a small amount of lanthanide rare earth particles to the framework material, and placing it in a CV...

Embodiment 3

[0043] The internal cavity of the metal box of the phase change system is 140mm long, 100mm wide, and 30mm thick. In the process of modifying the paraffin phase change material, the density of the paraffin phase change material used is about 0.9g / cm 3 .

[0044] S1, first prepare the skeleton material, 5% mass content of high thermal conductivity carbon fiber and 95% mass content of mesophase pitch through 6MPa pressure, 450 ° C foaming process, 900 ° C carbonization process, prepared a density of 0.46 g / cm 3 of the skeleton material. The framework material is processed to a near-net shape state.

[0045] S2, depositing SiC material in special CVD equipment, performing ceramic toughening on the framework material, the process time is about 6 hours, and the density of the framework material is increased to 0.53g / cm 3 .

[0046] S3, adding a small amount of copper metal particles to the framework material, and placing it in a CVD device to catalyze the deposition of CNTs, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com