Method for producing fuel ethanol and elaeagnus angustifolia polysaccharide by using elaeagnus angustifolia fruits as raw materials

A technology of fuel ethanol and sand date, applied in the direction of microorganism-based methods, biofuels, biochemical equipment and methods, etc., can solve the problem of single product, achieve the effect of saving energy consumption, saving steam consumption, and broadening the use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

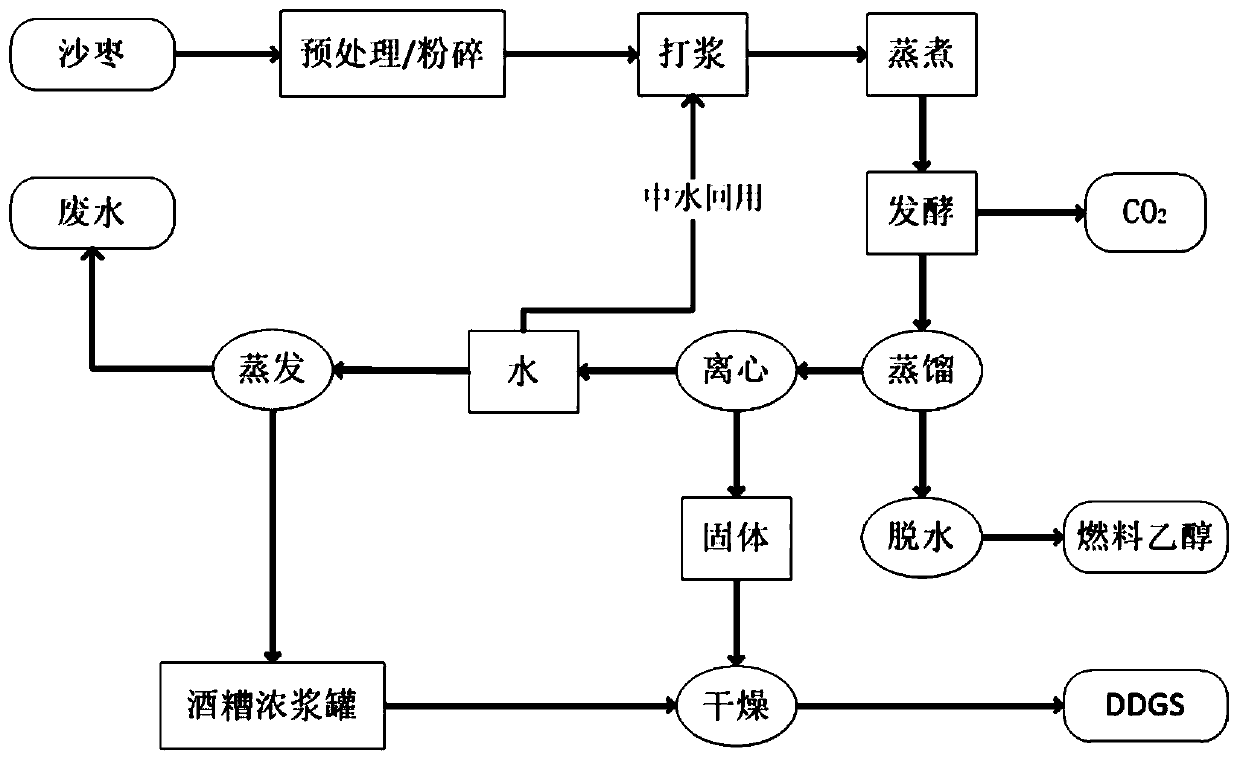

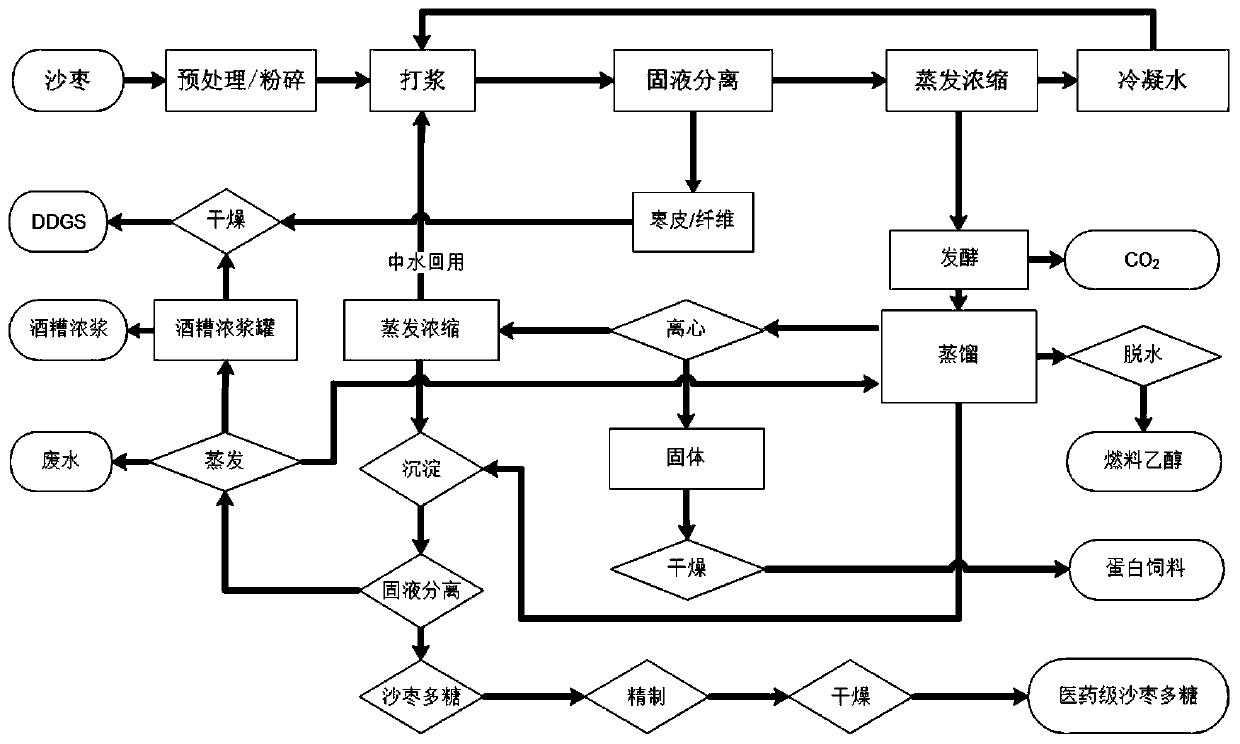

[0052] see figure 2 , embodiment 1 is that the technology of producing fuel ethanol Elaeagnus erae polysaccharides as raw material is as follows:

[0053] Add 30kg of the date powder from which impurities and fruit stones have been removed, and add process water with a pH of 3.5 to 5.0 to make a slurry to obtain date pulp.

[0054] The jujube pulp is separated from the solid and liquid, and the clear mash is sent directly to the fermentation tank; after the separation, the solid is composted or dried to produce feed;

[0055] The clear mash directly enters the fermentation tank, inserts yeast, adds antibacterial agent, and stirs and ferments at 30-34°C for 36-40 hours; in the tank, it is fermented by yeast to generate alcohol, and sterile air is introduced during the fermentation process to keep the yeast Vitality, when the concentration of residual sugar in the mash is lower than 0.5%, the fermentation is terminated to obtain fermented mature mash;

[0056] The mature mash...

Embodiment 2

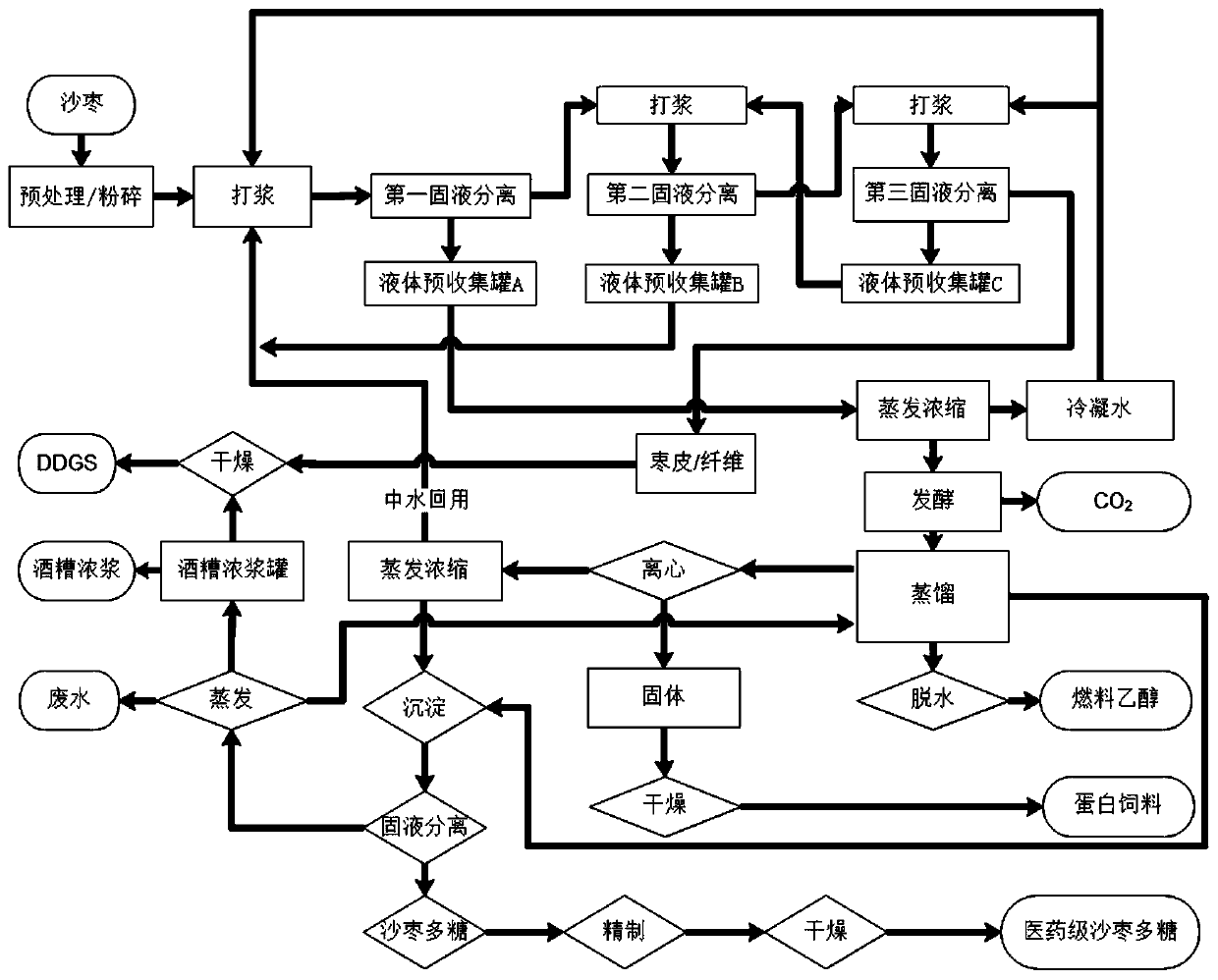

[0066] see image 3 , embodiment 2 is that the technology of producing fuel ethanol Elaeagnus erae polysaccharides as raw material is as follows:

[0067] Add 175kg of the date powder from which impurities and fruit stones have been removed, and add process water with a pH of 3.5 to 5.0 to make a pulp to obtain date pulp. The mass concentration of the date pulp is controlled to be 15 to 30%, and the sugar content is about 15%;

[0068] Jujube pulp has been subjected to three solid-liquid separation processes such as beating, washing, and separation (such as Figure 5 shown), the clear liquid after each separation is collected, the clear liquid of the second solid-liquid separation is used for beating of the first solid-liquid separation, and the clear liquid of the third solid-liquid separation is used for the beating of the second solid-liquid separation , the clear liquid collected by the first solid-liquid separation is subjected to multi-effect evaporation and concentrati...

Embodiment 3

[0079] see Figure 4 , Figure 5 , embodiment 3 is that the technology of producing fuel ethanol Elaeagnus erae polysaccharides as raw material is as follows:

[0080] Add 220kg of the date powder from which impurities and fruit stones have been removed, to process water with a pH of 3.5 to 5.0 containing nutrient salts, and beat to obtain jujube pulp. The mass concentration of the jujube pulp is controlled to be 20 to 35%;

[0081] The jujube pulp is preheated to 30-60°C by the heat exchanger through the steam waste heat from the distillation and dehydration section, and pectinase is added in a proportion of 0.05-0.1%, and kept for 1-2 hours, and then undergoes multiple grinding, washing, and separation. Collect the supernatant liquid, carry out multi-effect evaporation and concentration, and concentrate the supernatant to a sugar content of 16-24%; the concentrated mash is directly sent to the fermentation tank; the separated solids are composted or dried to produce feed; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com