Method for preparing dielectric layer based on anisotropic wet etching, dielectric layer and flexible pressure sensor

A pressure sensor and wet etching technology, applied in the field of flexible sensors, can solve the problems of high manufacturing cost and single shape, and achieve the effects of low cost, strong flexibility and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

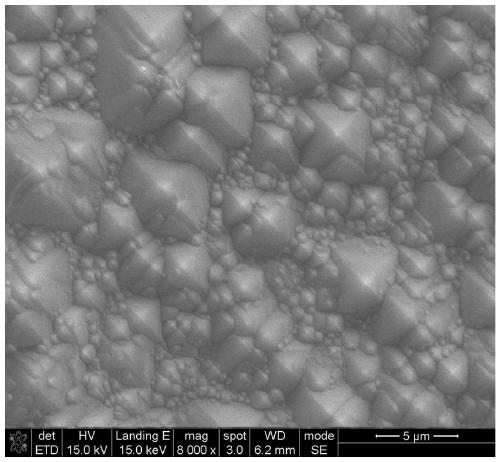

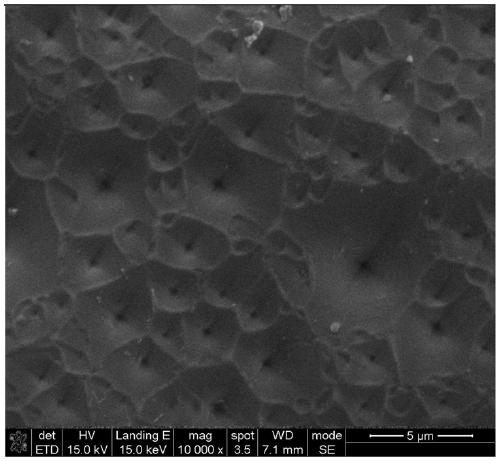

[0038] A method for preparing a dielectric layer based on anisotropic wet etching, comprising the following steps:

[0039] Step 1: Preparation of ion gel

[0040] According to the ratio of mass ratio of 1:7, polyvinylidene fluoride-hexafluoropropylene copolymer (P(VDF-HFP)) and acetone were added into the beaker, placed on a magnetic stirrer at room temperature, at a speed of 800r / min Stir for 1h. To prevent the volatilization of acetone, the beaker must be sealed with tin foil. After P(VDF-HFP) was completely dissolved in acetone, 1-ethyl-3-methylimidazolium bis(trifluoromethylsulfonyl)amide (abbreviated as [EMI][TFSA]) was added into the beaker as the ion Conductor, and continue to stir at room temperature at a speed of 800r / min for 1h, after the stirring is completed, the ion gel can be prepared.

[0041] Step 2: Make a template

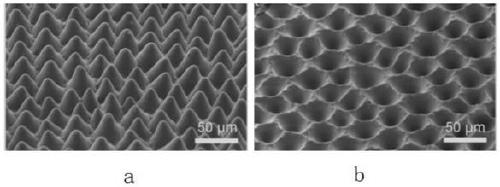

[0042] First, add deionized water and HF solution into the beaker at a ratio of 1:9 by volume, and then put a silicon wafer (N-type single t...

Embodiment 3

[0055] Apply the method for preparing the dielectric layer in Example 1, wherein the immersion etching time in the template preparation step is changed from 60 min to 75 min, and the obtained dielectric layer is packaged into a flexible pressure sensor with the same conductive electrodes.

[0056] Such as image 3 , Figure 4 As shown, the curve numbered 3 is the sensitivity curve of the flexible pressure sensor, and the sensitivity is 78.2kPa at a pressure of 44Pa -1 , which is lower than that of the sensor with an etching time of 60 minutes. And when the pressure is 30kPa, the sensitivity is still 29.7kPa -1 , which is lower than that of the sensor with an etching time of 60 minutes. The flexibility of the sensor means that when the sensor is bent by 180°, it still works normally.

[0057] By adjusting the process parameters according to the content of the present invention, the dielectric layer of the present invention can be prepared, and exhibit the performance basica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com