Preparation method of carbon-based supercapacitor electrode material with high electrochemical performance

A technology for supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of resource waste, environmental pollution, and low added value, and achieve the effect of simple method and increased specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Take 5g of methylene blue and 2gKOH in a mortar and mix evenly, then put it into a corundum crucible, and immediately put it into a tube furnace, blow in nitrogen, set the heating rate to 5°C / min, raise the temperature to 800°C, and hold for 90min , 5°C / min cooling rate. After the sample is naturally cooled to room temperature, use deionized water to rinse and filter the sample repeatedly until it is neutral, then put the sample in an oven and dry it at 80°C for 10 hours, and finally collect the sample and name it A-MBCP ; According to the same conditions, methylene blue was directly carbonized, and the sample without KOH activation treatment was named MBCP. Methylene blue in industrial wastewater is discharged into nature without treatment, which will cause serious environmental problems. Therefore, it can be fabricated into a high-performance supercapacitor, which can convert wastes that pollute the environment into energy storage materials.

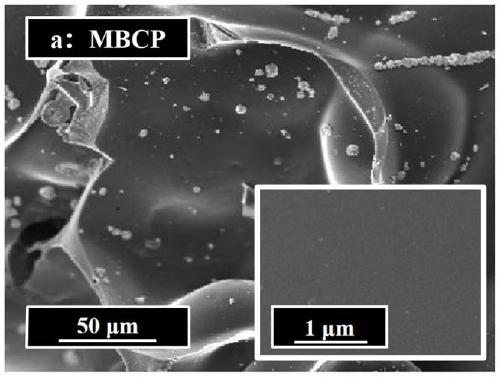

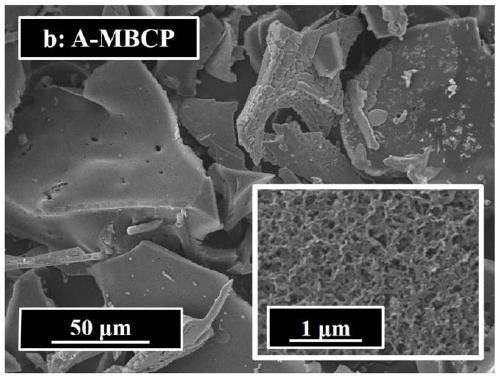

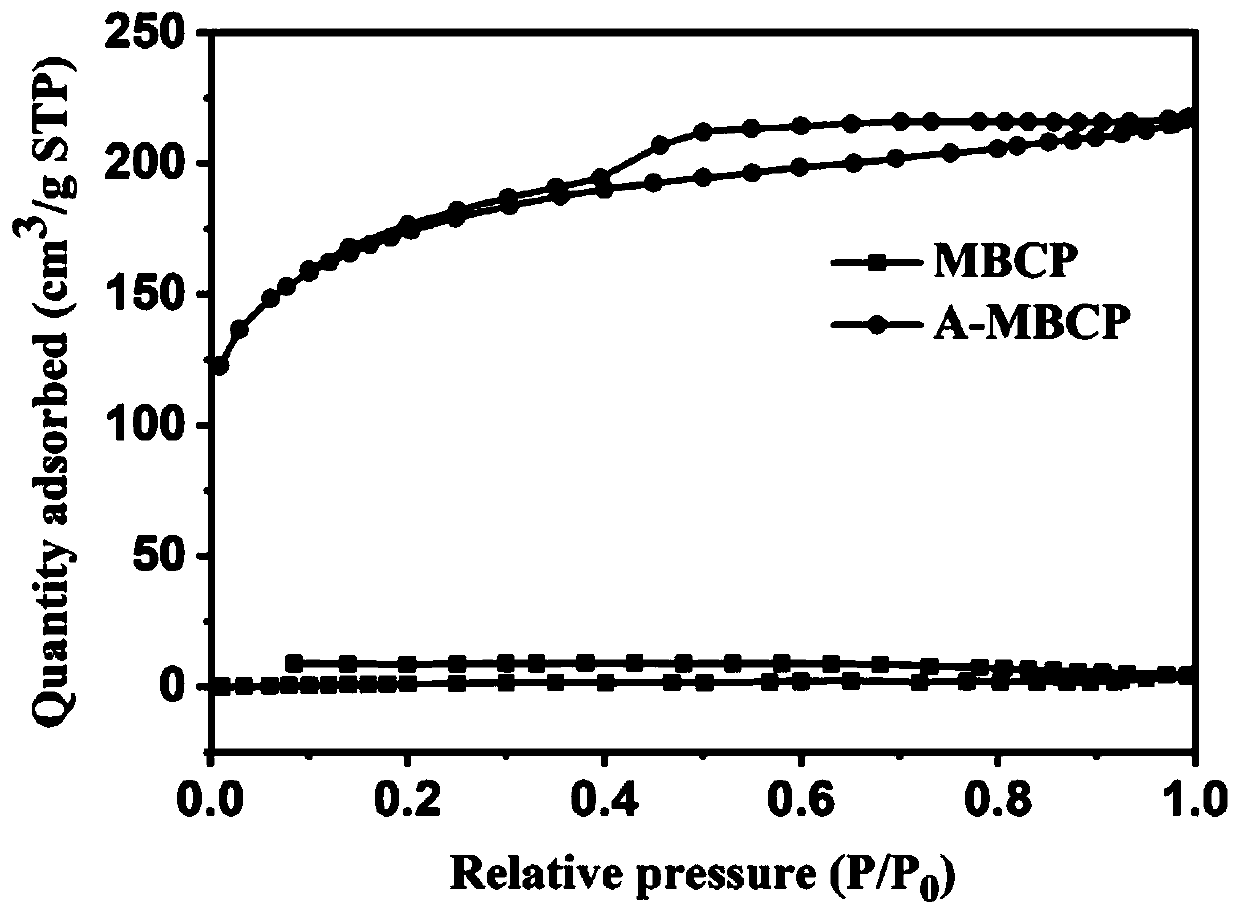

[0034] The electron mi...

Embodiment 2

[0038] Take 6g of methylene blue and 3g of KOH and mix evenly in a mortar, then put it into a corundum crucible, and put it into a tube furnace immediately. Nitrogen was introduced, and the heating rate was set to 3°C / min, the temperature was raised to 1000°C, the temperature was kept for 60 minutes, and the cooling rate was 10°C / min. After the tube furnace cooled down to room temperature, the samples were taken out. Rinse and filter the sample repeatedly with deionized water until it is neutral, then place the sample in an oven and dry it at 105°C for 8 hours, and finally collect the sample and name it A-MBCP. The sample that was directly carbonized with methylene blue and not activated by KOH was named MBCP. The resulting two active materials are used as electrode materials for supercapacitors. The active material: acetylene black: polytetrafluoroethylene suspension is made into an electrode at a ratio of 80:15:5, and the electrolyte is KOH solution. The electrode is subje...

Embodiment 3

[0040] Take 2g of methylene blue and 5g of KOH and mix them evenly in a mortar, then put them into a corundum crucible, and put them into a tube furnace immediately. Nitrogen was introduced, and the heating rate was set to 2°C / min, the temperature was raised to 700°C, kept for 2 hours, and the cooling rate was 10°C / min. After the tube furnace cooled down to room temperature, the samples were taken out. Rinse and filter the sample repeatedly with deionized water until it is neutral, then place the sample in an oven and dry it at 60°C for 24 hours, and finally collect the sample and name it A-MBCP. The resulting active materials are used as electrode materials for supercapacitors. The active material: acetylene black: polytetrafluoroethylene suspension at 80:15:5 is made into an electrode, and the electrolyte is Na 2 SO 4 Solution, conduct constant current charge and discharge GCD test on the electrode, calculate the energy density and power density, and compare with the valu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap