Preparation method of integrally formed solid-state battery

A solid-state battery and electrode technology, applied in the manufacture of electrolyte batteries, battery electrodes, secondary batteries, etc., can solve the problems of poor interface compatibility, difficult to guarantee physical interface contact, and poor product consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

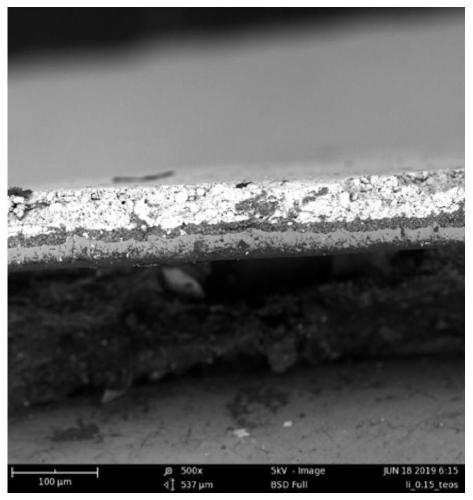

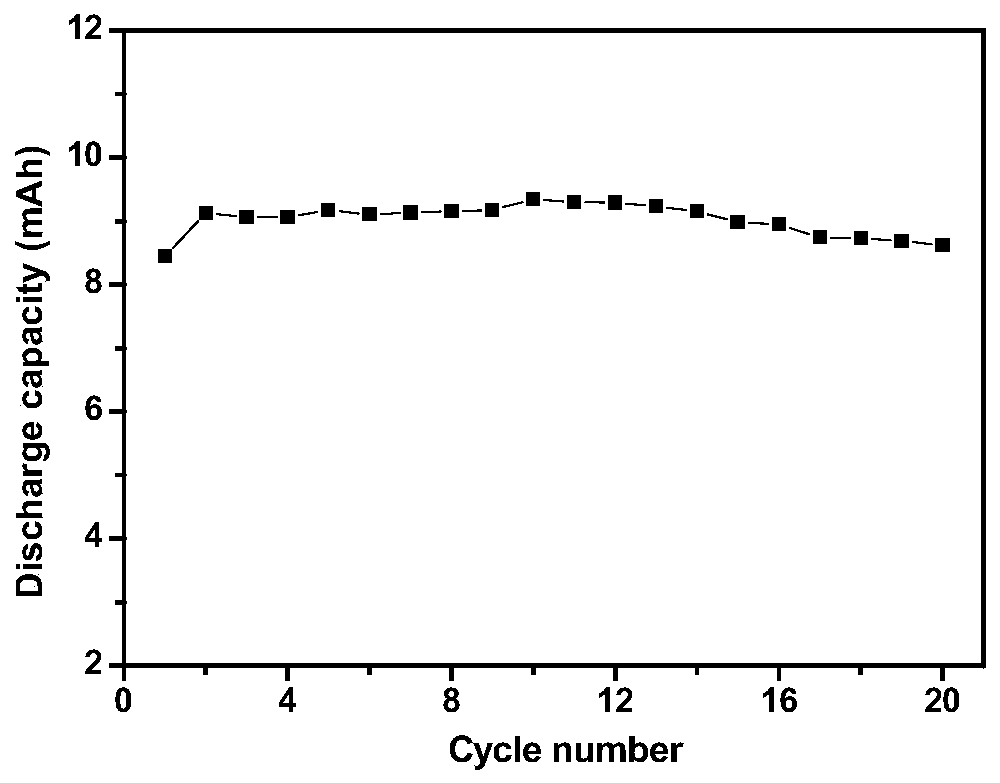

Image

Examples

preparation example Construction

[0040] The invention discloses a method for preparing an integrated solid-state battery. The method includes the following steps:

[0041] 1) Preparation of composite positive electrode layer: a mixture of 80-88 parts by mass of modified or unmodified positive electrode active material, 2-10 parts by mass of conductive agent, 2 parts by mass of binder, 6 parts by mass of polymer and lithium salt , 2 parts by mass of inorganic electrolyte, respectively dissolved in 400 parts by mass of organic solvent to obtain positive electrode slurry; apply positive electrode slurry on aluminum foil, dry at 70°C for 1 hour, and dry at 70°C for 24 hours in vacuum , the loading capacity of single-sided positive electrode is 15-16mg / cm 2 ;

[0042] Wherein, the mass ratio of the polymer to the lithium salt is preferably 1:10-4:1.

[0043] 2) Preparation of solid electrolyte slurry: Dissolve 1-2 parts by mass of lithium salt and 4-5 parts by mass of polymer in 50 parts by mass of organic solve...

Embodiment 1

[0062] A method for preparing an integrated solid-state battery, the specific preparation process comprising:

[0063] 1) Preparation of composite cathode layer

[0064] Mix 80g of positive electrode material NCA with 10g of conductive agent Super P, add a mixture of 8g of polypropylene carbonate (PPC) and lithium salt (LiTFSI), 2g of inorganic electrolyte LLZTO and 400ml of N-methyl-2-pyrrolidone, and stir for 3 hours to obtain a positive electrode Slurry: Coat the positive electrode slurry on aluminum foil, dry at 70°C for 1 hour, and dry at 70°C for 24 hours in vacuum, the positive electrode loading on one side is 15mg / cm 2 ; Wherein, polymer and lithium salt mass ratio are 1:10.

[0065] 2) Preparation of solid electrolyte slurry

[0066] Mix 4g of polypropylene carbonate PPC with 1g of lithium salt LiTFSI, add 50g of dimethylacetamide DMAc, stir at 70°C for 12 hours to make it evenly mixed, add 0.8g of inorganic electrolyte LLZTO, stir for 6 hours until uniformly disper...

Embodiment 2

[0075] The invention relates to a preparation method of an integrated solid-state battery, in which an integrated structure of an electrode and an electrolyte is sequentially stacked and assembled to form a solid-state battery. Specific preparation process:

[0076] 1) Preparation of composite cathode layer

[0077] 88g ternary cathode material LiNi 0.8 mn 0.1 co 0.1 o 2 Mix with 2g conductive agent acetylene black, add a mixture of 6g polymer cyano rubber and lithium salt LiFSI, 2g inorganic electrolyte Li1 +x al x Ge 2-x (PO 4 ) 3 , 2g binder PVDF and 400ml N-methyl-2-pyrrolidone, stir for 3 hours to obtain positive electrode slurry, apply positive electrode slurry on aluminum foil, dry at 70°C for 1 hour, and dry at 70°C for 24 hours in vacuum , the loading capacity of single-sided positive electrode is 16mg / cm 2 ;

[0078] 2) Preparation of solid electrolyte slurry

[0079] Mix 5g polymer cyano rubber with 2g lithium salt LiFSI, add 50g dimethylformamide, stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com