Polymer modified asphalt waterproof coiled material with good aging resistance and preparation method thereof

A technology of modified asphalt and waterproof membrane, which is applied in chemical instruments and methods, building structures, building insulation materials, etc., and can solve the problems of asphalt's high temperature resistance, fluidity resistance, low temperature flexibility, and aging resistance. , achieve excellent waterproof and anti-corrosion performance, strong binding force, and achieve the effect of absorption and heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

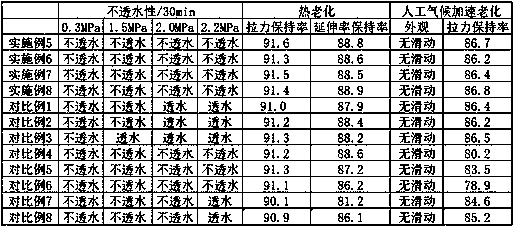

Examples

Embodiment 1

[0026] A polymer-modified asphalt waterproof membrane with good aging resistance, including a base layer, the upper and lower surfaces of the base base are provided with modified asphalt layers, the upper and lower modified asphalt layers are covered with isolation layers, and the base layer is polymer Ester tire, the isolation layer is PVC film.

[0027] The modified asphalt layer is made of the following raw materials in parts by weight: 85 parts of asphalt, 10 parts of styrene-butadiene rubber, 10 parts of SBS, 10 parts of polymethyl silicone resin, 5 parts of vermiculite powder, 2 parts of fatty alcohol polyoxyethylene ether, carboxylate 10 parts of wave resin, 5 parts of spodumene powder, 10 parts of cordierite powder, 2 parts of silicon carbide powder, 5 parts of alkyl polyglycosides, 2 parts of double decyl methyl hydroxyethyl ammonium chloride, 10 parts of rubber oil and o- 5 parts of dioctyl phthalate.

[0028] Among them, the particle size of the vermiculite powder ...

Embodiment 2

[0030] A polymer-modified asphalt waterproof membrane with good aging resistance, including a base layer, the upper and lower surfaces of the base base are provided with modified asphalt layers, the upper and lower modified asphalt layers are covered with isolation layers, and the base layer is polymer Vinyl, the isolation layer is PE film.

[0031] The modified asphalt layer is made of the following raw materials in parts by weight: 70 parts of asphalt, 10 parts of styrene-butadiene rubber, 5 parts of SBS, 15 parts of polymethyl silicone resin, 5 parts of vermiculite powder, 5 parts of fatty alcohol polyoxyethylene ether, carboxylate 5 parts of wave resin, 8 parts of spodumene powder, 5 parts of cordierite powder, 2 parts of silicon carbide powder, 3 parts of alkyl polyglycoside, 2 parts of double decyl methyl hydroxyethyl ammonium chloride, 5 parts of aromatic oil and ophthalmic oil 5 parts of dioctyl phthalate.

[0032] Among them, the particle size of the vermiculite powd...

Embodiment 3

[0034] A polymer-modified asphalt waterproof membrane with good aging resistance, including a base layer, the upper and lower surfaces of the base base are provided with modified asphalt layers, the upper and lower modified asphalt layers are covered with isolation layers, and the base layer is polymer Vinyl, the isolation layer is PET film.

[0035] The modified asphalt layer is made of the following raw materials in parts by weight: 90 parts of asphalt, 5 parts of styrene-butadiene rubber, 15 parts of SBS, 10 parts of polymethyl silicone resin, 10 parts of vermiculite powder, 2 parts of fatty alcohol polyoxyethylene ether, carboxylate 10 parts of wave resin, 5 parts of spodumene powder, 10 parts of cordierite powder, 1 part of silicon carbide powder, 5 parts of alkyl polyglycosides, 1 part of double decyl methyl hydroxyethyl ammonium chloride, 10 parts of rubber oil and o- Dioctyl phthalate 2 parts.

[0036] Among them, the particle size of the vermiculite powder is 600 mes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com