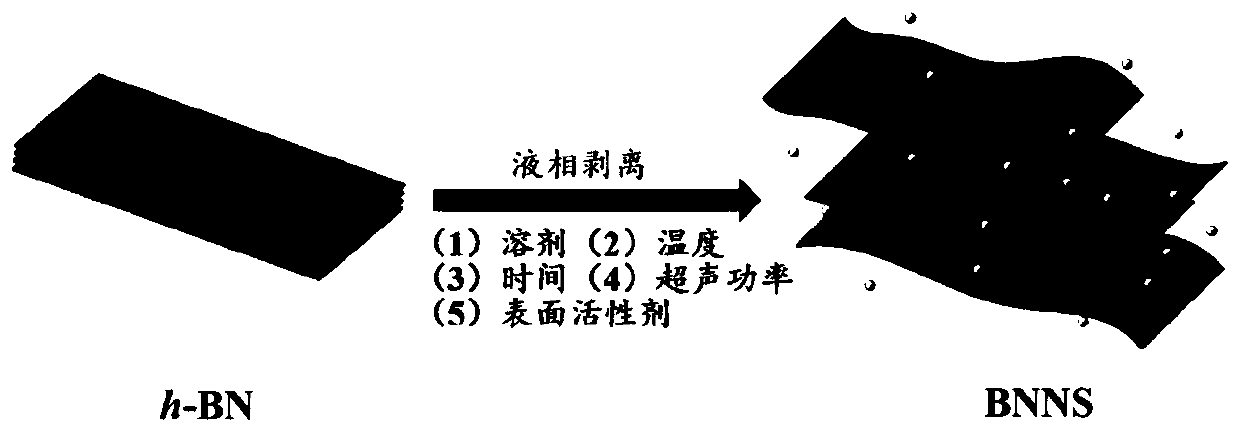

Method for preparing boron nitride nanosheet (BNNS) by efficiently stripping hexagonal boron nitride (h-BN)

A high-efficiency, h-bn technology, applied in the field of materials, can solve the problems of inability to obtain lamellar BNNS, BNNS structural damage, and low BNNS yield, and achieve the effects of less defects, low cost, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The present invention is a method for efficiently stripping h-BN to prepare boron nitride nanosheets, the specific steps are as follows:

[0045] (1) Weigh 150 mg of sodium citrate dihydrate crystals and place them in a beaker, pour 15 ml of deionized water into it and stir to dissolve, then add 25 ml of isopropanol.

[0046](2) Weigh 150 mg of h-BN, add it to the beaker in step (1), stir and disperse it, put it into an ultrasonic cleaner for 2 hours, and set the power to 200W.

[0047] (3) Add the solution obtained by ultrasonication in step (2) into a hydrothermal reaction kettle (volume 100ml), react for 24 hours, and set the temperature at 180°C.

[0048] (4) After stirring the solution obtained from the reaction in step (3) evenly, put it into an ultrasonic cleaner for 3 minutes and set the power to 100W.

[0049] (5) The solution obtained in step (4) is subjected to low-speed centrifugation, the centrifuge speed is 1000rpm, and the time is 5min. After centrifugat...

Embodiment 2

[0054] The present invention is a method for efficiently stripping h-BN to prepare boron nitride nanosheets, the specific steps are as follows:

[0055] (1) Weigh 150 mg of sodium citrate and place it in a beaker, pour 10 ml of deionized water into it and stir to dissolve, then add 25 ml of DMF.

[0056] (2) Weigh 150 mg of h-BN, add it into the beaker of step (1), stir and disperse it, put it into an ultrasonic cleaner for 2 hours, and set the power to 200W.

[0057] (3) Add the solution obtained by ultrasonication in step (2) into a hydrothermal reaction kettle (volume 100ml), react for 24 hours, and set the temperature at 180°C.

[0058] (4) After stirring the solution obtained from the reaction in step (3) evenly, put it into an ultrasonic cleaner for 3 minutes and set the power to 100W.

[0059] (5) The solution obtained in step (4) is subjected to low-speed centrifugation, the centrifuge speed is 1000rpm, and the time is 5min. After centrifugation, the supernatant is ta...

Embodiment 3

[0064] The difference between this embodiment and embodiment 1 is only: do not add sodium citrate.

[0065] The TEM picture of the BNNS that the present embodiment makes is as Figure 10 As shown, the SEM picture is as Figure 11 shown. It can be seen that compared with Examples 1 and 2, the stripping effect of h-BN becomes worse, and the yield of BNNS obtained by centrifugation in this example is 20.8%, indicating that sodium citrate has a significant effect on the stripping effect of h-BN.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com