Landfill leachate treatment method

A technology for landfill leachate and a treatment method, applied in the field of landfill leachate treatment, can solve the problems of shortening the service life of the membrane, high effluent COD, poor ability to adapt to changes in water quality, etc. biochemical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

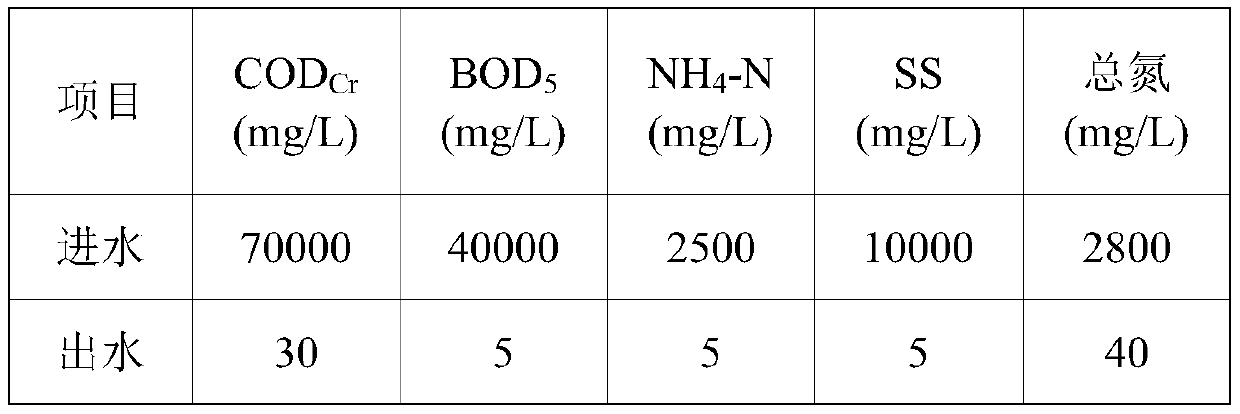

Embodiment 1

[0038] A leachate treatment method, comprising the steps of:

[0039] S1. Primary sedimentation: Garbage leachate enters the primary sedimentation tank to remove large suspended particles;

[0040] S2. Oxidation and precipitation: the supernatant flowing out of the primary sedimentation tank enters the first oxidation tank, and hydrogen peroxide and ferrous sulfate with a molar ratio of 1:1 are added to the first oxidation tank, and the ferrous sulfate in the first oxidation tank is controlled. The concentration of iron salt is 150mg / L, the reaction time is 1h, and the pH value is adjusted to 3 during the process, and the hydroxyl radicals generated by the reaction of hydrogen peroxide and ferrous sulfate oxidize and decompose organic matter;

[0041] Then enter the first settling tank, add lye to the first settling tank, adjust the pH value of the leachate in the first settling tank to be 10, and aerate for 1 hour, so that the iron ion in the leachate of the first settling ta...

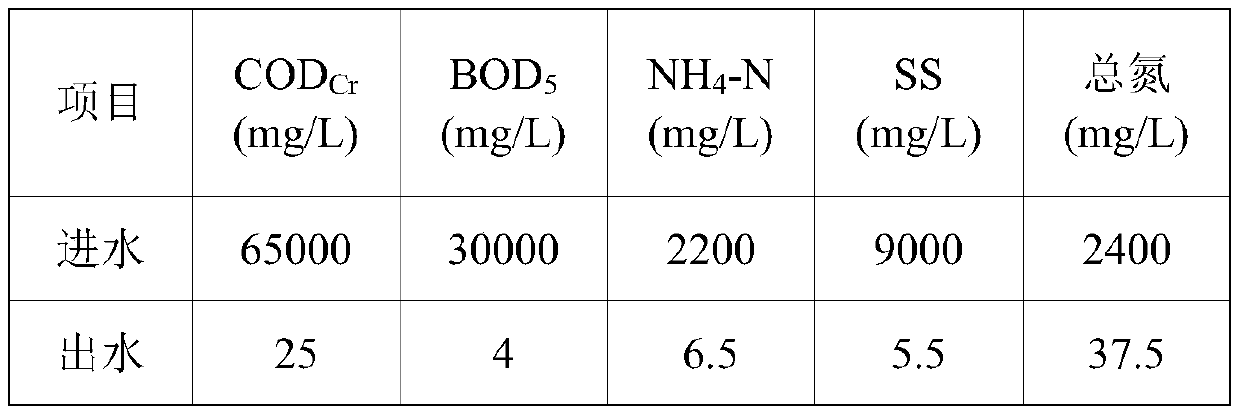

Embodiment 2

[0051] A leachate treatment method, carried out according to the method in Example 1, the difference is that S2, oxidation, precipitation: the supernatant that flows out in the primary sedimentation tank enters in the first oxidation tank, and the molar ratio of adding in the first oxidation tank is 1:1 hydrogen peroxide and ferrous chloride, and the concentration of ferrous salt in the first oxidation tank is controlled to 100mg / L, the reaction time is 1.5h, and the pH value is adjusted to 3 during the process, hydrogen peroxide and sulfurous acid The hydroxyl radicals generated by the iron reaction oxidize and decompose organic matter;

[0052] Then enter the first settling tank, add lye to the first settling tank, adjust the pH value of the leachate in the first settling tank to 9.5, and aerate for 1.5h, so that the iron ion in the leachate of the first settling tank is precipitated as hydroxide Iron, while removing residual hydrogen peroxide;

[0053] The supernatant of t...

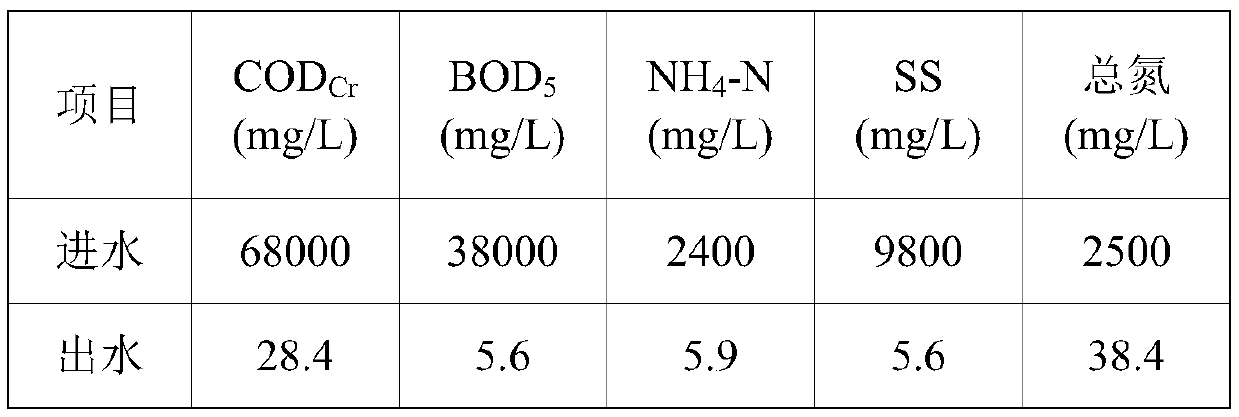

Embodiment 3

[0057] A leachate treatment method, carried out according to the method in Example 1, the difference is that S2, oxidation, precipitation: the supernatant that flows out in the primary sedimentation tank enters in the first oxidation tank, and the molar ratio of adding in the first oxidation tank is 1:1 hydrogen peroxide and ferrous chloride, and the concentration of ferrous salt in the first oxidation tank is controlled to 200mg / L, the reaction time is 1h, and the pH value is adjusted to 3 during the process, hydrogen peroxide and ferrous sulfate The hydroxyl radicals generated by the reaction oxidize and decompose organic matter;

[0058] Then enter the first settling tank, add lye to the first settling tank, adjust the pH value of the leachate in the first settling tank to 10.5, and aerate for 1 hour, so that the iron ion in the leachate of the first settling tank is precipitated as ferric hydroxide , while removing residual hydrogen peroxide;

[0059] The supernatant of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com