Additive suitable for oil pipe cleaning and descaling and preparation method of additive

A technology of additives and oil pipes, applied in the field of oil pipe cleaning and descaling additives and its preparation, can solve a large number of problems, equipment and personnel safety hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

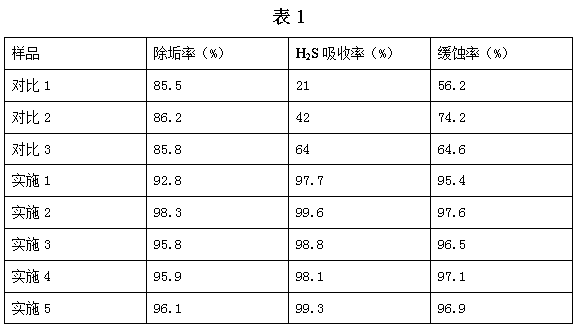

Examples

Embodiment 1

[0025] The components and mass percentage content of the additive are: fluorocarbon alkyl amide 10%, fluorocarbon imidazoline quaternary ammonium salt 3%, hydrocarbon imidazoline quaternary ammonium salt 5%, CH 2 CH 2 CONH 2 CH 2 CH 2 NHCH 2 CH 2 OH 5%, OP-10 1%, Pingpingjia 25 1%, Ethylene Glycol Methyl Ether 5%, Methanol 10%, Water 60% Mix and compound each component and stir evenly.

[0026] Add 10% by mass of the above compounded additives into the acid solution for oil pipe cleaning and descaling (10% by mass hydrochloric acid), and then use the acid solution to clean the oil pipe. Cleaning results: The inner surface of the oil pipe is cleaned, no residual oxides and scales, no secondary rust, no pitting, no obvious H 2 S smell, excellent cleaning effect.

Embodiment 2

[0028] The components and mass percentage content of the additive are: 12% of fluorocarbon alkylamide, 5% of fluorocarbon imidazoline quaternary ammonium salt, 5% of hydrocarbon imidazoline quaternary ammonium salt, CH 2 CH 2 CONH 2 CH 2 CH 2 NHCH 2 CH 2 OH 10% OP-10 2%, Pingpingjia 25 2%, Ethylene glycol methyl ether 5%, Ethylene glycol ether 5%, Ethanol 15%, Water 51% Mix and compound each component and stir evenly.

[0029] Add the above compounded additives at 15% by mass to the acid solution for oil pipe cleaning and descaling (hydrochloric acid with a mass percentage of 10%), and then use the acid solution to clean the oil pipe. Cleaning results: The inner surface of the oil pipe is cleaned, no residual oxides and scales, no secondary corrosion, no pitting corrosion, no obvious H 2 S smell, excellent cleaning effect.

Embodiment 3

[0031] The components and mass percentage of the additive are: 15% fluorocarbon alkyl amide, 5% fluorocarbon imidazoline quaternary ammonium salt, 10% hydrocarbon imidazoline quaternary ammonium salt, CH 2 CH 2 CNCH 2 CH 2 NHCH 2 CH 2 OH 5%, OP-10 3%, Pingpingjia 25 3%, Ethylene Glycol Propyl Ether 10%, Methanol 5%, Ethanol 5%, n-Butanol 5%, Water 34%. Stir well.

[0032] Add 10% by mass of the above compounded additives into the acid solution for oil pipe cleaning and descaling (15% by mass sulfamic acid), and then use the acid solution to clean the oil pipe. Cleaning results: The inner surface of the oil pipe is cleaned, no residual oxides and scales, no secondary rust, no pitting, no obvious H 2 S smell, excellent cleaning effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com