Supported catalyst, and preparation method and application thereof

A technology of supported catalysts and combustion catalysts, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as environmental pollution, unfavorable industrialization, equipment corrosion, etc., achieve high activity and reduce consumption , good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0079] For the preparation method of cerium-zirconium composite oxide, refer to patent CN106268856A.

[0080] For the preparation method of titanium-manganese composite oxide, refer to the patent CN104226233B.

[0081] For the preparation method of cerium-zirconium-copper composite oxide, refer to patent CN105727965B.

[0082] Analytic method is as follows in the embodiment of the application:

[0083] On-line chromatographic analysis was performed using an Agilent 7890A gas chromatograph equipped with a FID detector.

[0084] The conversion rate of this application is calculated as follows:

[0085]

[0086] where CH 4in and CH 4out CH for inlet and outlet respectively 4 concentration.

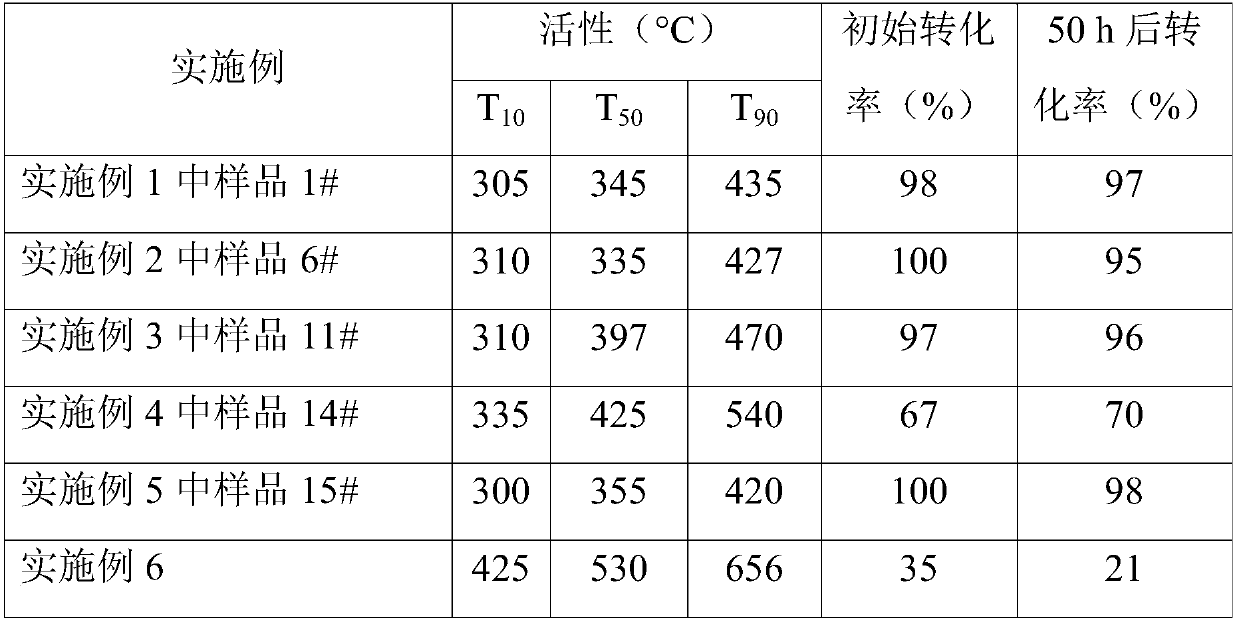

Embodiment 1

[0088] Accurately weigh 5.00 g of the cerium-titanium composite oxide carrier prepared by the homogeneous precipitation method, the cerium-titanium molar ratio is 1:1, the particle size is 40-60 mesh, and the solid particles are placed in the reaction tube with a hydrogen volume content of 10%. The hydrogen and nitrogen mixed gas is used for reduction, the reduction temperature is 400°C, and the reduction time is 2h. After cooling down to room temperature, inject 0.42mL of 13.0% Pd(NO 3 ) 2 Aqueous solution and 2mL deionized water, after standing for 6h, washed, filtered, and the obtained solid was placed in an oven at 120°C for 10h. The dried solid was calcined at 550 °C for 2 h under air atmosphere. A CeTi-Pd catalyst was obtained, marked as sample 1#. Wherein, the weight content of Pd in sample 1# is 1%.

[0089] Using the same preparation method as sample 1#, the difference is that the volume content of hydrogen in the mixed gas is 3%, the reduction temperature is 50...

Embodiment 2

[0095] Accurately weigh 5.00 g of the cerium-zirconium oxide carrier prepared by the co-precipitation method, the cerium-zirconium molar ratio is 1:1, the particle size is 40-60 mesh, put the solid particles in a beaker, and add 60 mL of hydrazine hydrate with a mass concentration of 10%. Solution, after stirring for 180min, suction filter, wash 5 times with deionized water, inject 0.25mL mass fraction in the beaker and be 13.0% Pd(NO 3 ) 2 Aqueous solution and 2mL deionized water, after standing for 6h, washed, filtered, and the obtained solid was placed in an oven at 120°C for 10h. The dried solid was calcined at 550 °C for 2 h under air atmosphere. A CeZr-Pd catalyst was obtained, designated as sample 6#. Wherein, the weight content of Pd in sample 6# is 0.6%.

[0096] Using the same preparation method as sample 6#, the difference is that the stirring time is 2h, to obtain a supported CeZr-Pd catalyst, labeled 7#. Using the same preparation method as sample 6#, the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com