Plant formaldehyde-removing mud as well as preparation method and application thereof

A plant and aldehyde purification technology, applied in separation methods, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as unpleasant odor, inconvenient cleaning, tearing, etc., and achieve high formaldehyde removal efficiency, radiation prevention, and strong plasticity. and adhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

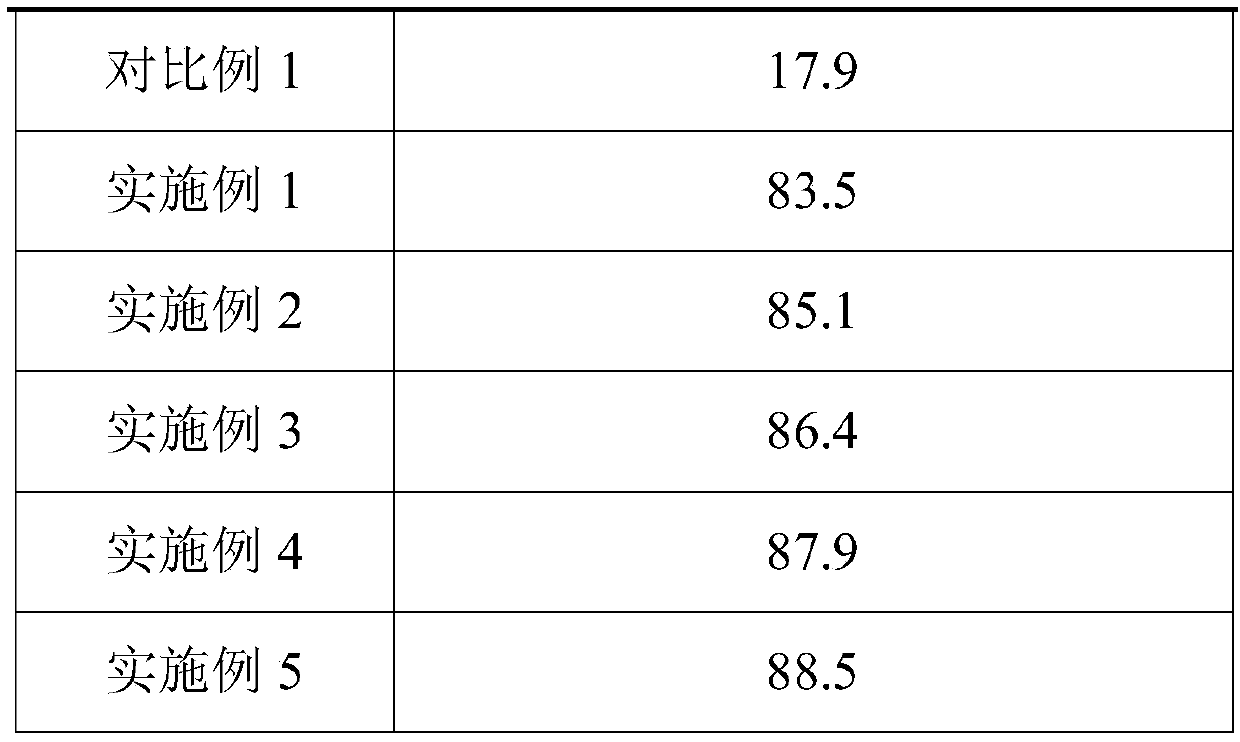

Embodiment 1

[0029] A preparation method of plant aldehyde net mud, comprising the following steps:

[0030] S1. Add 15kg of plant extracts to 70kg of ionized water and stir thoroughly for 30 minutes; the plant extracts include 7.5kg of tea extracts and 7.5kg of wormwood extracts; in practice, the plant extracts here are all dry powder shape;

[0031] S2. Provide 20kg of a mixed solution of titanium trichloride and titanium tetrachloride, then add 10kg of quartz sand, and react at a temperature of 120° C. for 3 hours to obtain a solid powder; wherein, titanium trichloride solution and titanium tetrachloride solution The concentration is 0.5mol / L, the mass ratio of titanium trichloride solution and titanium tetrachloride solution is 1:3; using the mixed solution of titanium trichloride and titanium tetrachloride as the precursor of titanium dioxide, it is prepared by reaction Titanium dioxide nanoparticles have an anatase phase structure and high crystallinity, uniform particle size distri...

Embodiment 2

[0037] A preparation method of plant aldehyde net mud, comprising the following steps:

[0038] S1. Add 20kg of plant extracts to 75kg of ionized water and stir thoroughly for 30 minutes; the plant extracts include 10kg of aloe extract and 10kg of pine needle extract;

[0039] S2. Provide 25kg of a mixed solution of titanium trichloride and titanium tetrachloride, then add 15kg of quartz sand, and react at a temperature of 140°C for 4h to obtain a solid powder; wherein, titanium trichloride solution and titanium tetrachloride solution The concentration is 0.5mol / L, the mass ratio of titanium trichloride solution and titanium tetrachloride solution is 1:3; using the mixed solution of titanium trichloride and titanium tetrachloride as the precursor of titanium dioxide, it is prepared by reaction Titanium dioxide nanoparticles have an anatase phase structure and high crystallinity, uniform particle size distribution of 3-20nm, easy to disperse, and have excellent photocatalytic a...

Embodiment 3

[0045] A preparation method of plant aldehyde net mud, comprising the following steps:

[0046] S1. Add 25kg of plant extracts to 75kg of ionized water and stir thoroughly for 30 minutes; plant extracts include 12.5kg of tea extracts and 12.5kg of aloe extracts;

[0047] S2. Provide 30 kg of a mixed solution of titanium trichloride and titanium tetrachloride, then add 15 kg of quartz sand, and react for 5 hours at a temperature of 160° C. to obtain a solid powder; wherein, titanium trichloride solution and titanium tetrachloride solution The concentration is 0.5mol / L, the mass ratio of titanium trichloride solution and titanium tetrachloride solution is 1:3; using the mixed solution of titanium trichloride and titanium tetrachloride as the precursor of titanium dioxide, it is prepared by reaction Titanium dioxide nanoparticles have an anatase phase structure and high crystallinity, uniform particle size distribution of 3-20nm, easy to disperse, and have excellent photocatalyti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com