Environment-friendly tert-carbonic acid organic silicone-acrylic modified copolymer emulsion for ceramic tile back adhesive

A technology of copolymerized emulsion and tertiary carbonic acid, applied in the directions of ester copolymer adhesives, adhesives, adhesive types, etc. problem, to achieve the effect of not easy to empty drum, convenient construction, good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

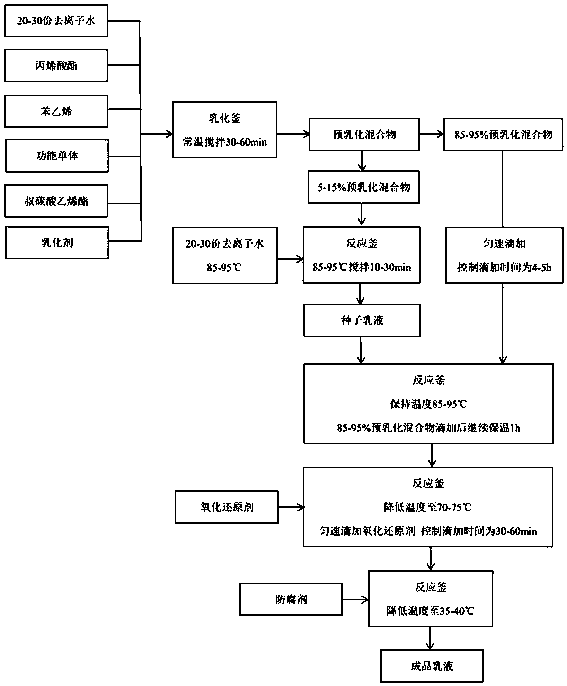

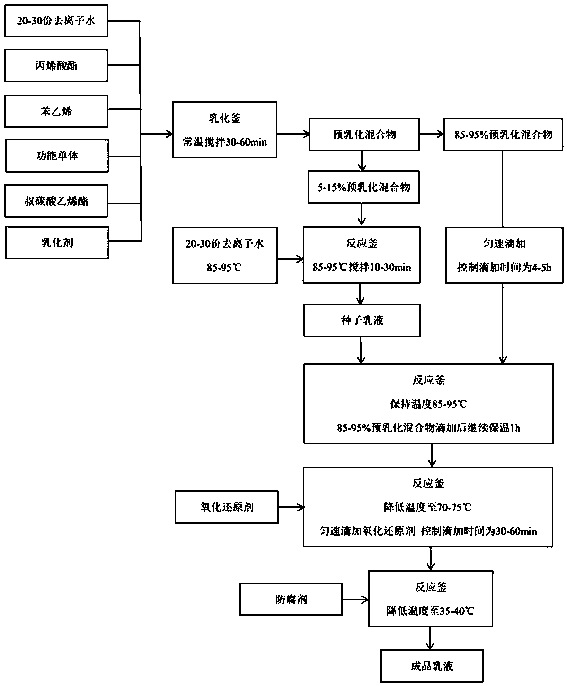

Method used

Image

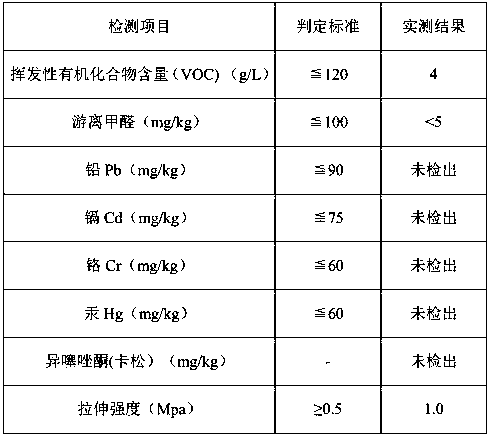

Examples

Embodiment 1

[0022] An environmentally friendly tertiary carbonic acid organosilicon acrylic modified copolymer emulsion for tile back glue, made of the following raw materials in parts by weight: 12 parts of styrene, 21 parts of acrylate, 12 parts of vinyl tertiary carbonate, and 2 parts of functional monomers , 3 parts of emulsifier, 0.2 part of water-based initiator, 0.3 part of redox agent, 0.1 part of preservative, 50 parts of deionized water;

[0023] Wherein, the functional monomer is methacryloxypropyltrimethoxysilane;

[0024] Described emulsifying agent is the mixture of 1.5 parts of dodecylsulfonic acid sodium salt and 1.5 parts of fatty alcohol polyoxyethylene ether;

[0025] The aqueous initiator is ammonium persulfate, potassium persulfate, sodium persulfate or a mixture of two or more in any proportion;

[0026] The redox agent is tert-butyl hydroperoxide, sodium bisulfite, sodium pyrosulfite or a mixture of two or more in any proportion;

[0027] The preservative is 2-bro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com