Self-repairing polymer electrolyte based on dynamic chemical bonds and application thereof in secondary lithium battery

A technology of polymers and electrolytes, applied in non-aqueous electrolyte batteries, electrolyte battery manufacturing, secondary batteries, etc., can solve problems such as improvement, degradation of polymer electrolyte oxidation stability, and limitation of energy density of lithium batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

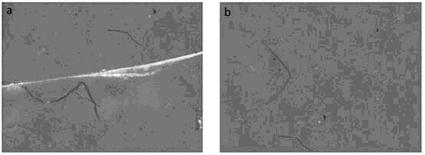

[0124] Under anhydrous and oxygen-free conditions, the Dissolve in N,N-dimethylacetamide and stir evenly, then add lithium difluorooxalate borate and dibutyltin dilaurate into the solution and stir until completely dissolved, in which polymer, lithium difluorooxalate borate and dilaurate The mass ratio of dibutyltin acid is 9:1:0.1. Then the solution was poured evenly on the tetrafluoro plate, and dried in a vacuum oven at 60° C. for 24 hours to obtain a PT-1 polymer solid electrolyte film. In order to observe the self-healing of the polymer electrolyte, the PT-1 film was first cut into two sections, and then placed under a microscope to observe the self-healing phenomenon of PT-1. It was found by optical microscope observation that the cuts in the PT-1 polymer electrolyte film disappeared within 1 min, showing excellent self-healing characteristics.

Embodiment 2

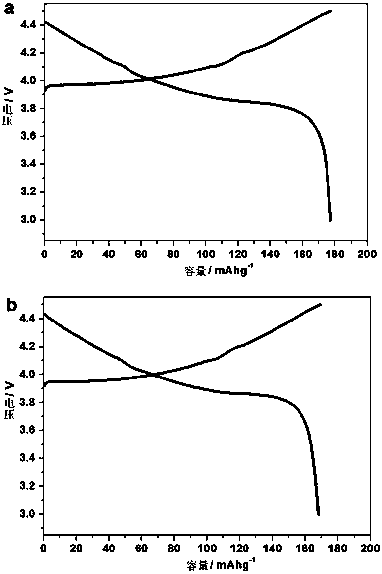

[0126] Under anhydrous and oxygen-free conditions, the Dissolve in N,N-dimethylacetamide and stir evenly, then add lithium bistrifluoromethylsulfonylimide and stannous octoate into the solution and stir until completely dissolved, in which the polymer, bistrifluoromethyl The mass ratio of lithium sulfonylimide to stannous octoate is 10:2:0.2. Then the solution was uniformly poured on the cellulose separator, and dried in a vacuum oven at 60° C. for 24 hours to obtain a PT-2 polymer solid electrolyte film. To evaluate the oxidation stability of the polymer electrolyte and its compatibility with high-voltage cathodes, PT-2 was assembled into LiCoO 2 / Li battery, then LiCoO 2 / Li battery is charged and discharged at a high voltage with a cut-off voltage of 4.4V, and the battery is subjected to a 180-degree bending test. The LiCoO 2 The discharge specific capacity of the / PT-2 / Li battery during the bending test is 140mAh / g, indicating that the battery can still maintain norma...

Embodiment 3

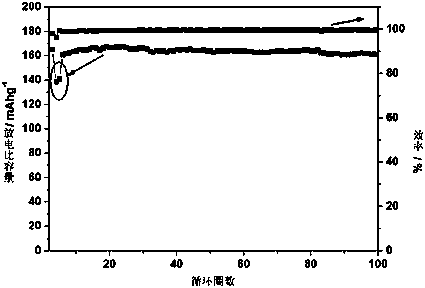

[0128] Under anhydrous and oxygen-free conditions, the Dissolve in N,N-dimethylacetamide and stir evenly, then add lithium bisfluorosulfonimide and dibutyltin dilaurate into the solution and stir until completely dissolved, in which polymer, bisfluorosulfonimide The mass ratio of lithium and dibutyltin dilaurate is 10:5:0.4. Then the solution was poured evenly on the tetrafluoro board, and dried in a vacuum oven at 60° C. for 24 hours to obtain a PT-3 polymer solid electrolyte film. To evaluate the oxidation stability of the polymer electrolyte and its compatibility with high-voltage cathodes, PT-3 was assembled into LiCoO 2 / Li battery, then LiCoO 2 The / Li battery is charged and discharged at a high voltage with a cut-off voltage of 4.5V. The LiCoO 2 The / PT-3 / Li battery can release a specific capacity of 180mAh / g at the 10th cycle, and can still release a specific capacity of 170mAh / g after 100 cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com