A kind of preparation method of titanium dioxide photocatalytic coating and coating thereof

A technology of titanium dioxide and nano-titanium dioxide, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, coatings, etc., can solve the problems of poor bonding force on the surface of the substrate and affect the catalytic activity of titanium dioxide, so as to improve the bonding force and provide light Effects of catalytic activity and high binding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

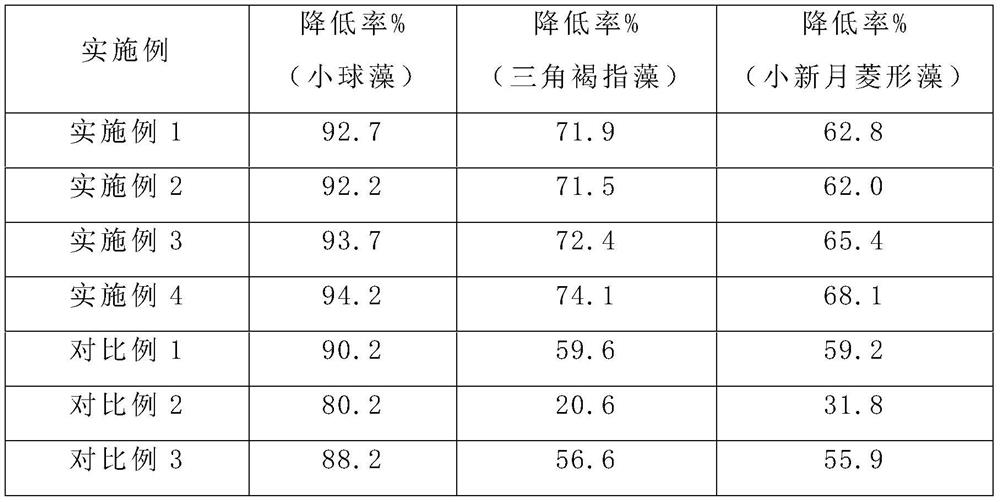

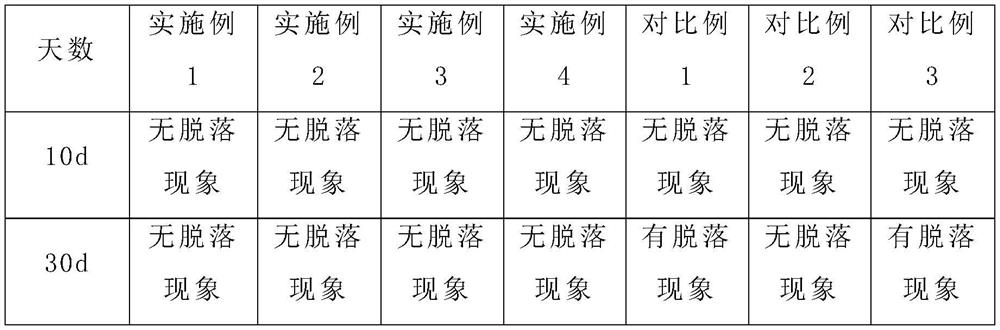

Examples

Embodiment 1

[0040] This embodiment relates to a titanium dioxide coating on the inner wall of a titanium tube. The preparation method includes the following steps:

[0041] (1). The surface treatment of the substrate includes sandblasting, washing with water, and drying in sequence;

[0042] (2). Configure the spraying slurry A: dissolve the zinc-silicon acrylate copolymer in methanol, the mass ratio of the zinc-silicon acrylate copolymer to methanol is 1:10, and prepare the spraying slurry A;

[0043] (3). Configure spraying slurry B: prepare a mixed solvent of methanol and deionized water, add titanium tetrachloride, stir evenly, and form a homogeneous TiO 2 Sol, the mol ratio of described methanol and titanium tetrachloride, deionized water is 1:3:5; The homogeneous TiO that will obtain 2 The sol was diluted to 1.5 times with deionized water to make a dispersion liquid; the aminopropyltriethoxysilane modified nano-titanium dioxide powder with a mass proportion of 0.5% was added to the d...

Embodiment 2

[0051] This embodiment relates to a titanium dioxide coating on the surface of a stainless steel pipe, the preparation method comprising the following steps:

[0052] (1). The surface treatment of the substrate includes sandblasting, washing with water, and drying in sequence;

[0053] (2). Configure the spraying slurry A: dissolve the zinc-silicon acrylate copolymer in ethanol, the mass ratio of the zinc-silicon acrylate copolymer to methanol is 1:12, and prepare the spraying slurry A;

[0054] (3). Configure spraying slurry B: prepare a mixed solvent of methanol and deionized water, add titanium sulfate, stir evenly, and form a homogeneous TiO 2 Sol, the mol ratio of described methanol and titanium sulfate, deionized water is 1:3:5; The homogeneous TiO that will obtain 2 The sol was diluted to 2 times with deionized water to make a dispersion liquid, and the aminopropyltriethoxysilane modified nano-titanium dioxide powder with a mass ratio of 0.5% was added to the dispersio...

Embodiment 3

[0062] This embodiment relates to a titanium dioxide coating on the inner wall of a titanium tube. The preparation method includes the following steps:

[0063] (1). The surface treatment of the substrate includes sandblasting, washing with water, and drying in sequence;

[0064] (2). Configure the spraying slurry A: dissolve the zinc-silicon acrylate copolymer in methanol, the mass ratio of the zinc-silicon acrylate copolymer to methanol is 1:12, and prepare the spraying slurry A;

[0065] (3). Configure spraying slurry B: prepare a mixed solvent of isopropanol and deionized water, add n-butyl titanate, stir evenly, and form a homogeneous TiO 2 Sol; The molar ratio of described Virahol and n-butyl titanate, deionized water is 1:4:6; The homogeneous TiO that will obtain 2 The sol was diluted to 2 times with deionized water to make a dispersion liquid, and the aminopropyltriethoxysilane modified nano-titanium dioxide powder with a mass ratio of 0.5% was added to the dispersion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com