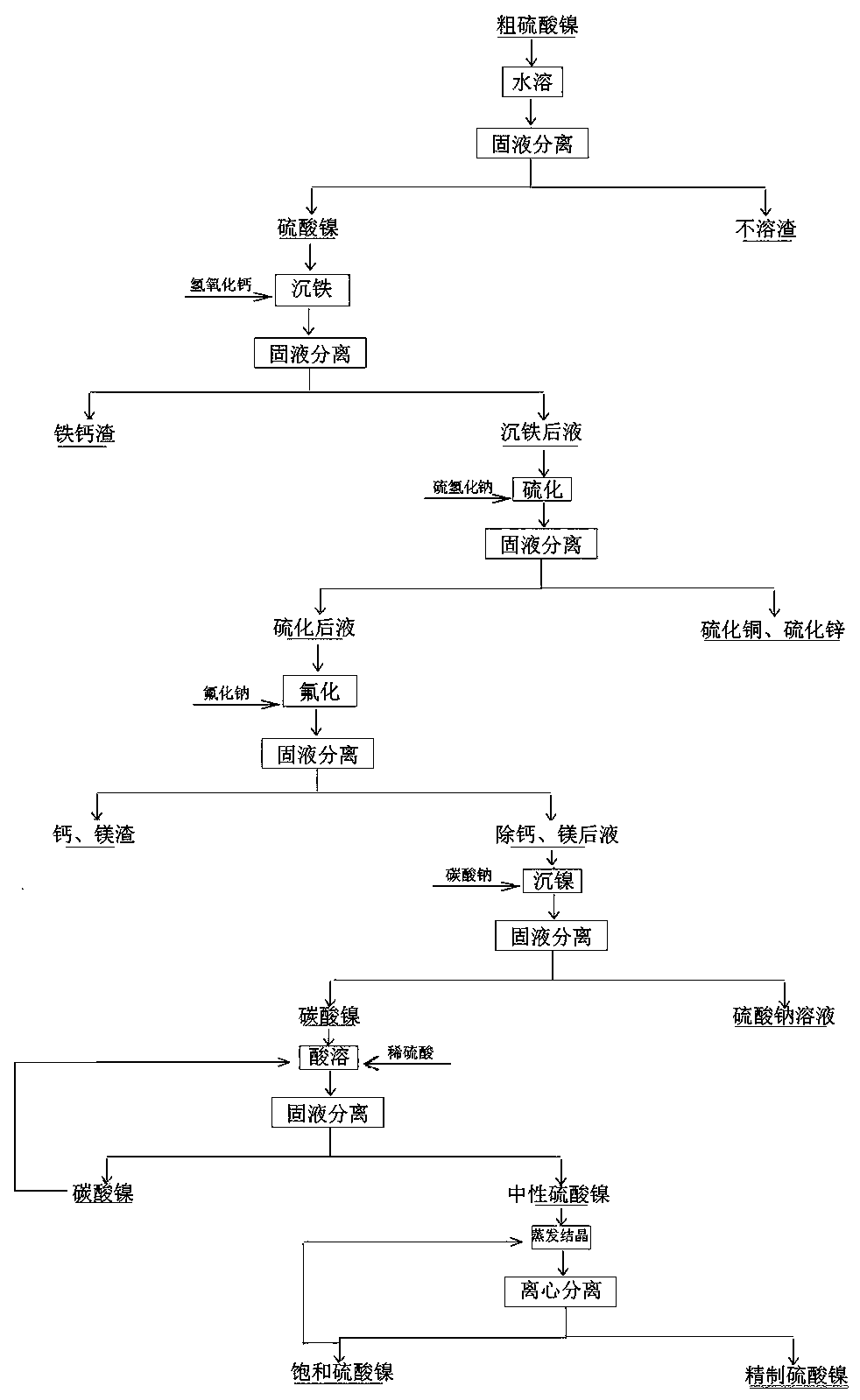

Process for refining battery-grade nickel sulfate from crude nickel sulfate

A process method, nickel sulfate technology, applied in the direction of nickel sulfate, etc., can solve the problems of increasing impurity elements in copper electrolyte, unfavorable copper electrolytic refining, etc., and achieve the effect of increasing filtration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] 1. 300KG crude nickel sulfate, using crude nickel sulfate purification process, to obtain refined nickel sulfate that meets the Class II standard of GB26524-2011, the direct recovery rate of nickel is 90-95%, attached table 1 and 2.

[0033] 2. 500KG crude nickel sulfate, using the crude nickel sulfate purification process, to obtain refined nickel sulfate that meets the II standard of GB / T 26524-2011, and the direct recovery rate of nickel is 90-95%, attached table 1 and 2.

[0034] 3. 1000KG crude nickel sulfate, using the crude nickel sulfate purification process, to obtain refined nickel sulfate that meets the II standard of GB / T 26524-2011, and the direct recovery rate of nickel is 90-95%, attached table 1 and 2.

[0035] Table 1 Composition of crude nickel sulfate

[0036] element Ni co Cu Fe Zn Ca Mg mn Pb Cd Content1 (wt%) 13.87 0.25 0.05 1.95 2.62 0.13 1.21 <0.01 <0.01 <0.01 Content 2 (wt%) 16.61 0.26 0.83 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com