Photovoltaic cable and preparation method thereof

A photovoltaic cable and compound rubber technology, which is applied to rubber insulators, organic insulators, etc., can solve the problems of affecting the service life of the product, weakening the effect of the outer layer, and increasing the difficulty of the process, so as to improve the mechanical strength, improve the uniformity of the product, and improve the process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

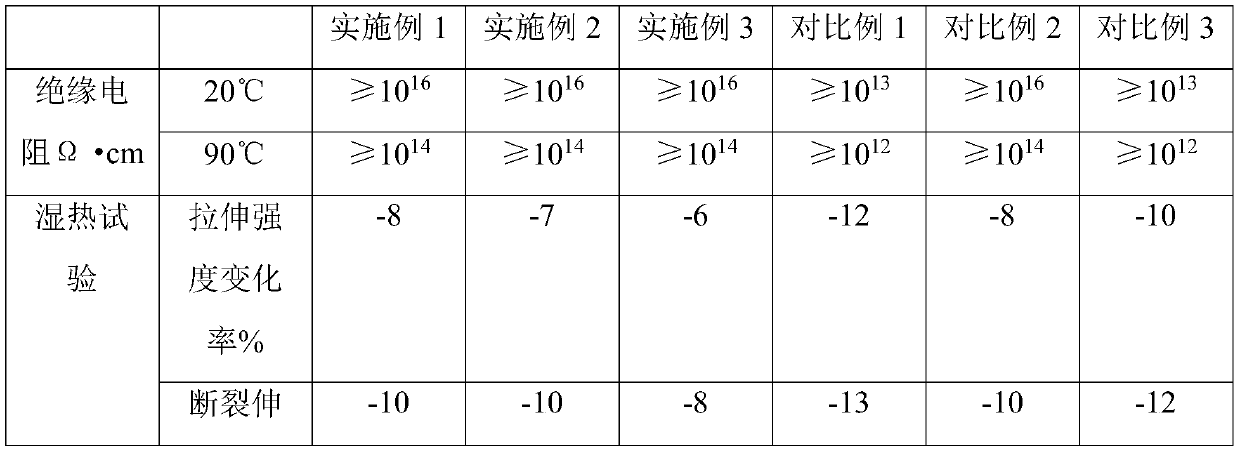

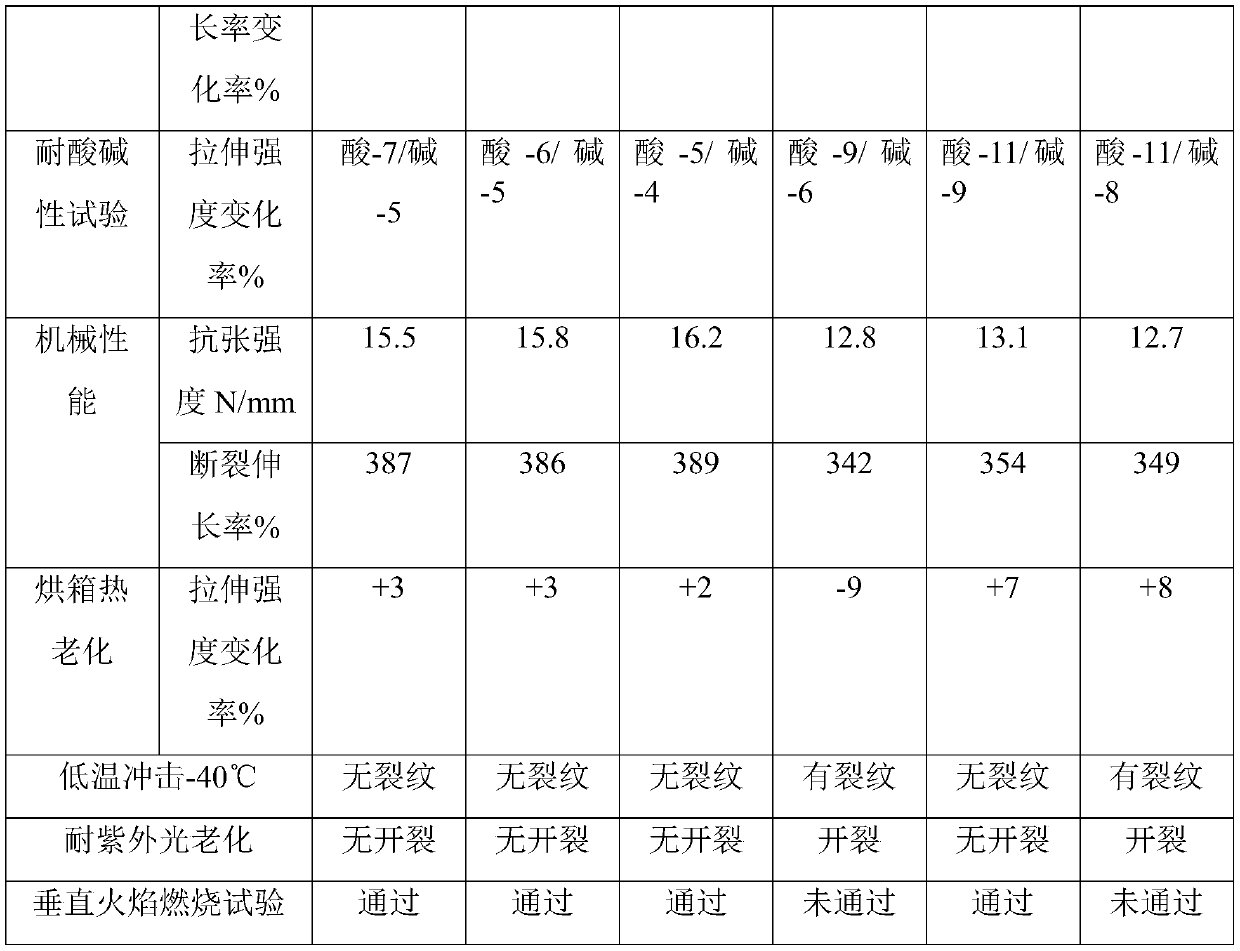

Embodiment 1

[0034] A method for preparing a photovoltaic cable, which comprises extruding compound rubber on the outer surface of a conductor core to form a protective layer, wherein the preparation method of the compound rubber is as follows:

[0035] (1) First mix 1kg of Hetian jade powder, 2kg of hexacyclic stone powder, 3kg of boron nitride powder, 3kg of nano-zinc acrylate, and 8kg of sepiolite powder to obtain a mixed powder, and organically modify it to obtain an organically modified mixed powder;

[0036] (2) Then mix the organic modified mixed powder with 15kg ethylene-vinyl acetate copolymer, 25kg acrylonitrile-butadiene-styrene copolymer, 38kg nitrile silicone rubber, 60kg chlorosulfonated polyethylene rubber, 1kg crosslinking agent , 2kg of ammonium polyphosphate-perlite powder coated with magnesium hydroxide on the surface, 2kg of anti-aging agent, 3kg of compatibilizer were transferred to the internal mixer and mixed for 10 minutes, then added 2kg of vulcanizing agent and 0.2...

Embodiment 2

[0049] A method for preparing a photovoltaic cable, which comprises extruding compound rubber on the outer surface of a conductor core to form a protective layer, wherein the preparation method of the compound rubber is as follows:

[0050] (1) First mix 1kg of Hetian jade powder, 3kg of hexacyclic stone powder, 2kg of boron nitride powder, 4kg of nano-zinc acrylate, and 5kg of sepiolite powder to obtain a mixed powder, and organically modify it to obtain an organically modified mixed powder;

[0051] (2) Then mix the organic modified mixed powder with 20kg ethylene-vinyl acetate copolymer, 20kg acrylonitrile-butadiene-styrene copolymer, 45kg nitrile silicone rubber, 50kg chlorosulfonated polyethylene rubber, 2kg crosslinking agent , 1kg of ammonium polyphosphate-perlite powder coated with magnesium hydroxide, 3kg of anti-aging agent, and 2kg of compatibilizer were transferred to the internal mixer and mixed for 15 minutes, then added 1kg of vulcanizing agent and 0.3kg of vulca...

Embodiment 3

[0064] A method for preparing a photovoltaic cable, which comprises extruding compound rubber on the outer surface of a conductor core to form a protective layer, wherein the preparation method of the compound rubber is as follows:

[0065] (1) First mix 1kg of Hetian jade powder, 2.5kg of hexacyclic stone powder, 2.5kg of boron nitride powder, 3.5kg of nano-zinc acrylate, and 6kg of sepiolite powder to obtain a mixed powder, and organically modify it to obtain an organically modified mixed powder;

[0066] (2) Then mix the organic modified mixed powder with 18kg ethylene-vinyl acetate copolymer, 22kg acrylonitrile-butadiene-styrene copolymer, 40kg nitrile silicone rubber, 55kg chlorosulfonated polyethylene rubber, 1.5kg cross-linked Agent, 1.5kg of ammonium polyphosphate-perlite powder coated with magnesium hydroxide on the surface, 2.5kg of anti-aging agent, 2.5kg of compatibilizer were transferred to the internal mixer and mixed for 12 minutes, then added 1.5kg of vulcanizin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com