Varnished cloth, preparation method thereof, copper-clad plate containing varnished cloth and application of varnished cloth

A technology of copper clad laminate and varnished cloth, applied in the field of flexible copper clad laminate and application, varnished cloth and its preparation, can solve the problems of high operating temperature and high melting point, and achieve good dielectric properties, good adhesion properties and excellent low temperature processability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

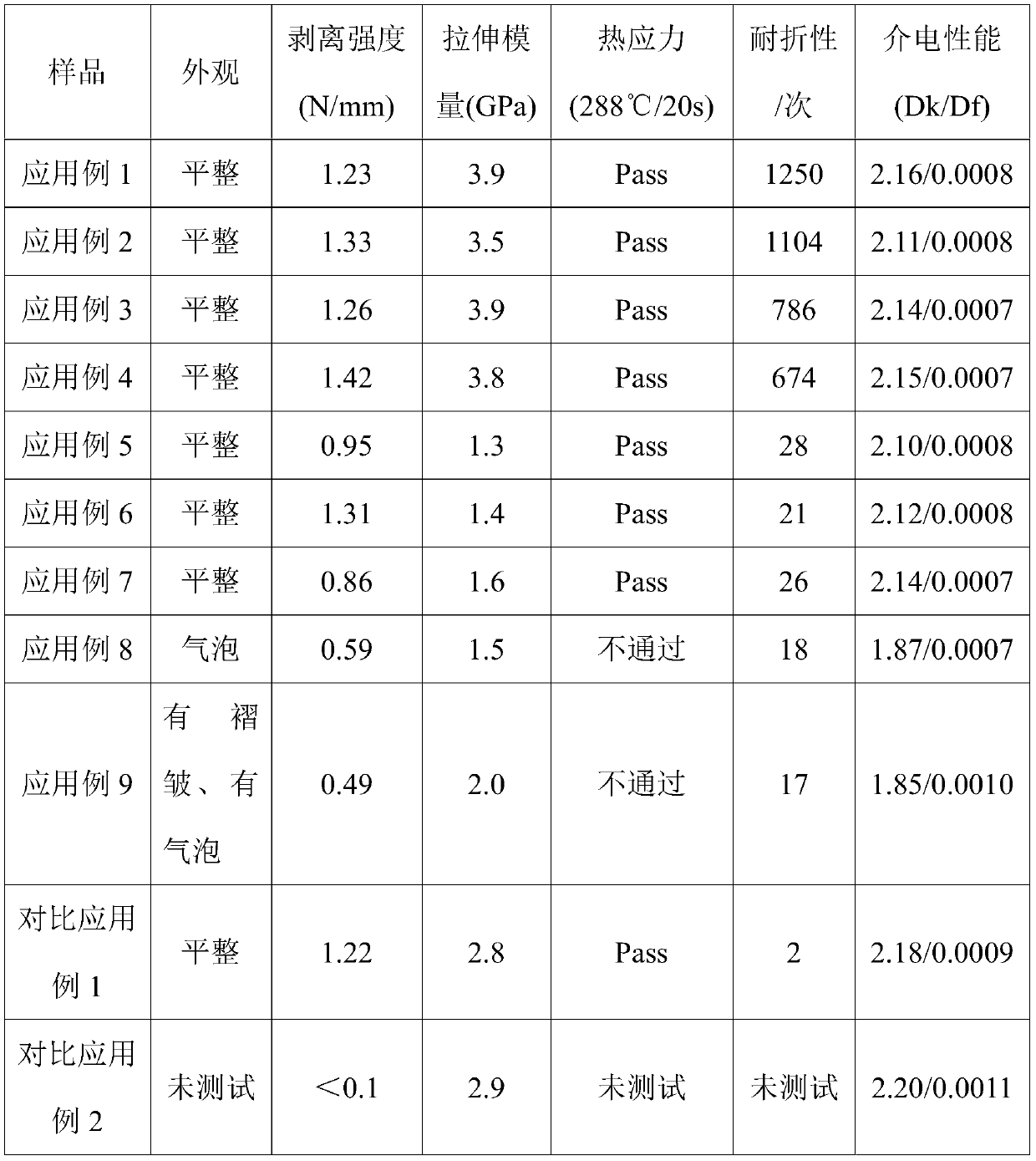

Examples

Embodiment 1

[0049] A kind of oilcloth, preparation method is as follows:

[0050] (1) Use polyimide fiber woven cloth to impregnate in PTFE emulsion, control the thickness of PTFE slurry by adjusting the gap between the nip rollers, then dry in an oven at 130°C for 8 minutes to remove the solvent, and sinter in an oven at 320°C , the time is 15 min, and finally a PTFE adhesive sheet with a thickness of 40 μm is obtained.

[0051] (2) Coat both sides of the bonding sheet with 17.5 μm (dry thickness) PFA emulsion, then dry in an oven at 160°C for 8 minutes to remove the solvent, and sinter in an oven at 370°C for 8 minutes to obtain a varnish with a thickness of 75 μm .

Embodiment 2

[0053] A kind of oilcloth, preparation method is as follows:

[0054] (1) Use liquid crystal polymer (LCP) fiber non-woven fabrics to impregnate in PTFE emulsion, control the thickness of the PTFE slurry by adjusting the gap between the nip rollers, then dry in a 130°C oven for 8min to remove the solvent, and then dry it in a 320°C oven The sintering was carried out for 15 minutes, and finally a PTFE bonded sheet with a thickness of 75 μm was obtained.

[0055] (2) Coat both sides of the adhesive sheet with 12.5 μm (dry thickness) PFA emulsion, then dry in an oven at 160°C for 8 minutes to remove the solvent, and sinter in an oven at 370°C for 8 minutes to obtain a varnished cloth with a thickness of 100 μm .

Embodiment 3

[0057] A kind of oilcloth, preparation method is as follows:

[0058] (1) Use aramid fiber non-woven fabric to impregnate in PTFE emulsion, control the thickness of the PTFE slurry by adjusting the gap between the nip rollers, then dry in an oven at 140°C for 5 minutes to remove the solvent, and sinter in an oven at 310°C, The time is 25 minutes, and finally a PTFE adhesive sheet with a thickness of 95 μm is obtained.

[0059] (2) Coat both sides of the bonding sheet with 27.5 μm (dry thickness) PFA emulsion, then dry in a 170°C oven for 10 minutes to remove the solvent, and sinter in a 360°C oven for 15 minutes to obtain a varnished cloth with a thickness of 150 μm .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com