A kind of multifunctional sealing assembly and preparation method thereof

A sealing component and multi-functional technology, applied in the direction of non-polymer adhesive additives, adhesive types, adhesives, etc., can solve problems such as cracking, degradation of equipment insulation performance, and accelerated oxidation and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

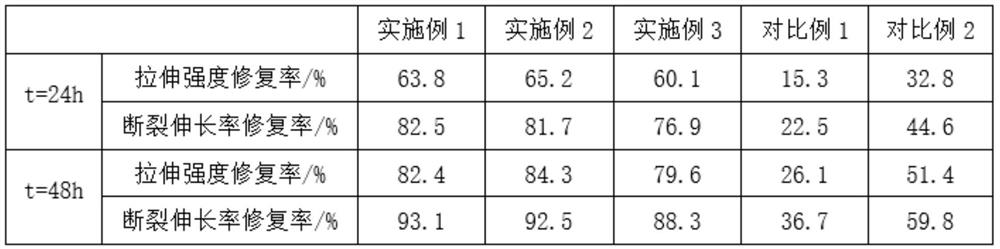

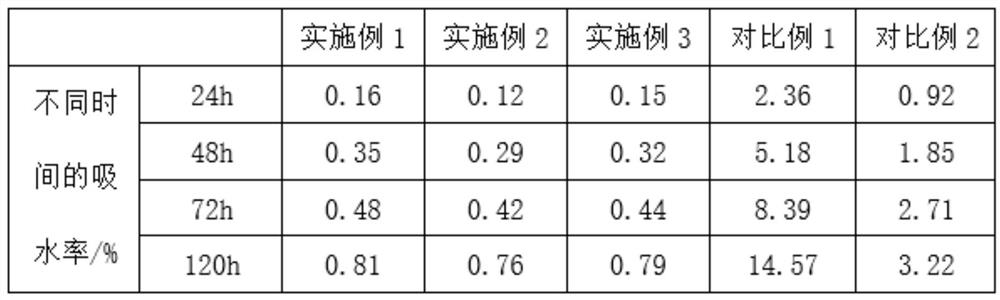

Examples

Embodiment 1

[0046] A multifunctional sealing component, the sealing component is composed of a sealing component and a curing component; the curing component is a room temperature curing agent; the sealing component is calculated in parts by weight and consists of the following components:

[0047] 30 parts of mercapto-terminated liquid nitrile rubber, 20 parts of epoxy resin, 3 parts of flame retardant, 3 parts of antistatic agent, 3 parts of plasticizer, 0.01 part of anti-ultraviolet agent, 0.06 part of diethylene glycol monobutyl ether, 4 parts - 0.03 part of amino-3-methylphenol, 0.05 part of dibutyltin;

[0048]The room temperature curing agent is synthesized from polycaprolactone triol, n-butanol and polyphosphoric acid.

[0049] The mass ratio of sealing component to curing component is 3:1.

[0050] The epoxy resin is bisphenol A type epoxy resin or bisphenol F type epoxy resin.

[0051] The plasticizer is dibutyl phthalate or dioctyl phthalate.

[0052] The anti-ultraviolet ag...

Embodiment 2

[0079] A multifunctional sealing component, the sealing component is composed of a sealing component and a curing component; the curing component is a room temperature curing agent; the sealing component is calculated in parts by weight and consists of the following components:

[0080] 35 parts of mercapto-terminated liquid nitrile rubber, 40 parts of epoxy resin, 3 parts of flame retardant, 5 parts of antistatic agent, 5 parts of plasticizer, 0.05 part of anti-ultraviolet agent, 0.1 part of diethylene glycol monobutyl ether, 4 parts - 0.1 part of amino-3-methylphenol, 0.2 part of dibutyltin;

[0081] The room temperature curing agent is synthesized from polycaprolactone triol, n-butanol and polyphosphoric acid.

[0082] The mass ratio of sealing component to curing component is 4:1.

[0083] The epoxy resin is bisphenol A type epoxy resin or bisphenol F type epoxy resin.

[0084] The plasticizer is dibutyl phthalate or dioctyl phthalate.

[0085] The anti-ultraviolet agen...

Embodiment 3

[0112] A multifunctional sealing component, the sealing component is composed of a sealing component and a curing component; the curing component is a room temperature curing agent; the sealing component is calculated in parts by weight and consists of the following components:

[0113] 40 parts of mercapto-terminated liquid nitrile rubber, 50 parts of epoxy resin, 5 parts of flame retardant, 8 parts of antistatic agent, 8 parts of plasticizer, 0.1 part of anti-ultraviolet agent, 0.16 part of diethylene glycol monobutyl ether, 4 parts - 0.16 part of amino-3-methylphenol, 0.5 part of dibutyltin;

[0114] The room temperature curing agent is synthesized from polycaprolactone triol, n-butanol and polyphosphoric acid.

[0115] The mass ratio of sealing component to curing component is 6:1.

[0116] The epoxy resin is bisphenol A type epoxy resin or bisphenol F type epoxy resin.

[0117] The plasticizer is dibutyl phthalate or dioctyl phthalate.

[0118] The anti-ultraviolet age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com