Mineral multifunctional fruit and vegetable soil conditioner and preparation method thereof

A soil conditioner and multi-functional technology, which is applied in the direction of soil conditioning materials, chemical instruments and methods, fertilizer mixtures, etc., can solve the problems of soil regeneration and repair ability decline, plant malnutrition, etc., and achieve the improvement of mineral element content and processing method Simple, powerful regenerative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

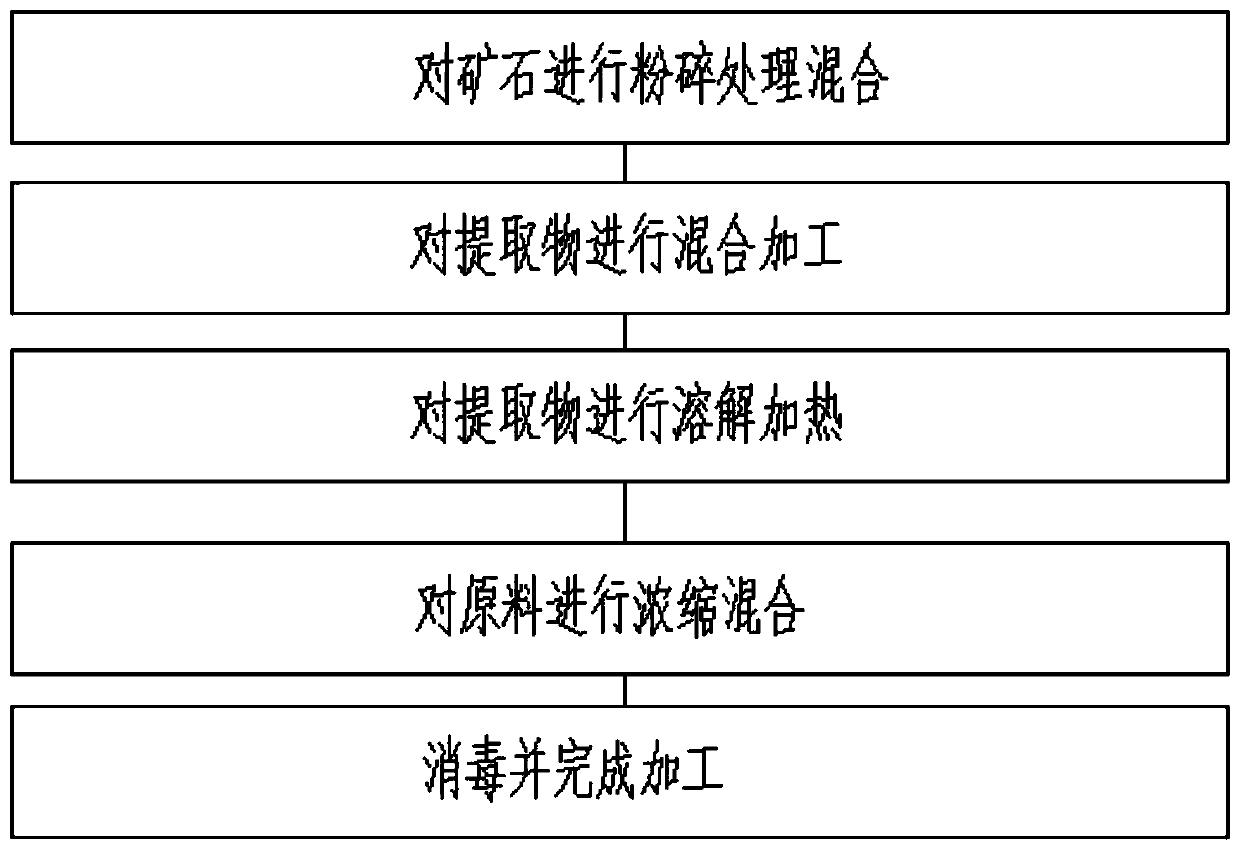

Method used

Image

Examples

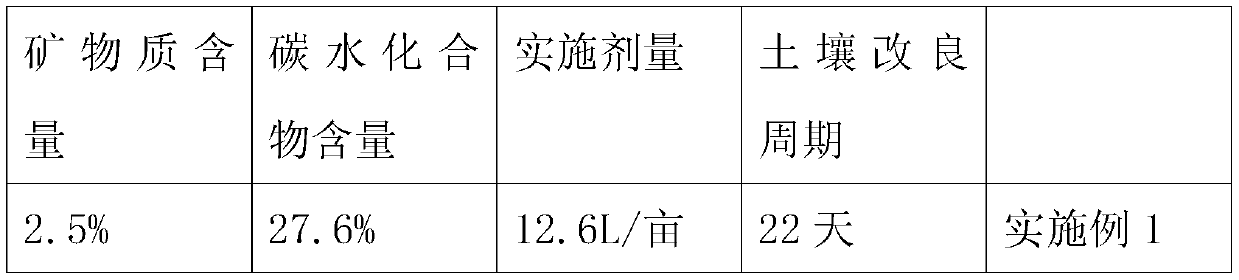

Embodiment 1

[0034] Weathered coal 4g, lime 8g, gypsum 7g, vermiculite 6g, chaetella extract 8g, kelp extract 1g, tomato extract 1.5g, cyanobacteria extract 3.2g, seaweed extract 2.3g, lignin 1.5g, resin glue 4g, urea 4.3g, polyacrylamide 1.8g, formaldehyde 1.5g, fruit residue 8g, mineral powder 0.9g, citric acid 4g, sodium dodecylbenzenesulfonate 5.5g, ferric chloride 3g, manganese chloride 3g.

[0035] The ore is pulverized and mixed firstly, weathered coal, lime, gypsum, and vermiculite are pulverized first, and after pulverized, mineral powder, fruit residue, and citric acid are added to fully mix;

[0036] Then the extracts are mixed and processed, and then the chaetella extract, kelp extract, tomato extract, cyanobacteria extract, laver extract, and lignin are fully sterilized by ultraviolet light, and then they are fully mixed and carried out Slowly heat, the temperature is controlled at 65°C for 15 minutes;

[0037]Then dissolve and heat the extract, add the extract in step S2 to ...

Embodiment 2

[0041] Weathered coal 2g, lime 3g, gypsum 4g, vermiculite 3.5g, hornweed extract 3g, kelp extract 0.3g, tomato extract 0.7g, cyanobacteria extract 0.9g, seaweed extract 0.6g, lignin 1.2g, Resin glue 1g, urea 1.2g, polyacrylamide 0.8g, formaldehyde 0.6g, fruit residue 4g, mineral powder 0.4g, citric acid 2g, sodium dodecylbenzenesulfonate 4.5g, ferric chloride 1.7g, chloride Manganese 1.1g.

[0042] The ore is pulverized and mixed firstly, weathered coal, lime, gypsum, and vermiculite are pulverized first, and after pulverized, mineral powder, fruit residue, and citric acid are added to fully mix;

[0043] Then the extracts are mixed and processed, and then the chaetella extract, kelp extract, tomato extract, cyanobacteria extract, laver extract, and lignin are fully sterilized by ultraviolet light, and then they are fully mixed and carried out Slowly heat, the temperature is controlled at 65°C for 15 minutes;

[0044] Then dissolve and heat the extract, add the extract in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com