Solid developer and its preparing process and usage

A color-developing agent and solid technology, applied in the field of solid color-developing agent and its manufacture, can solve the problems of only applicable, short storage time of color-developing agent, and large consumption of reagents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

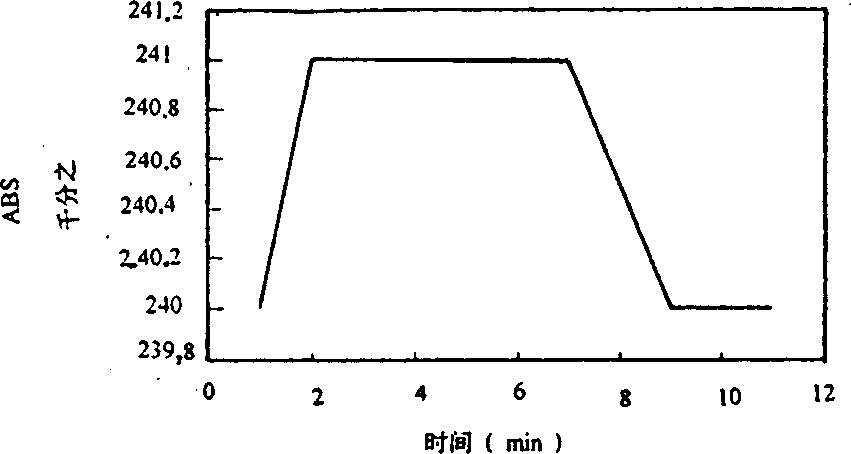

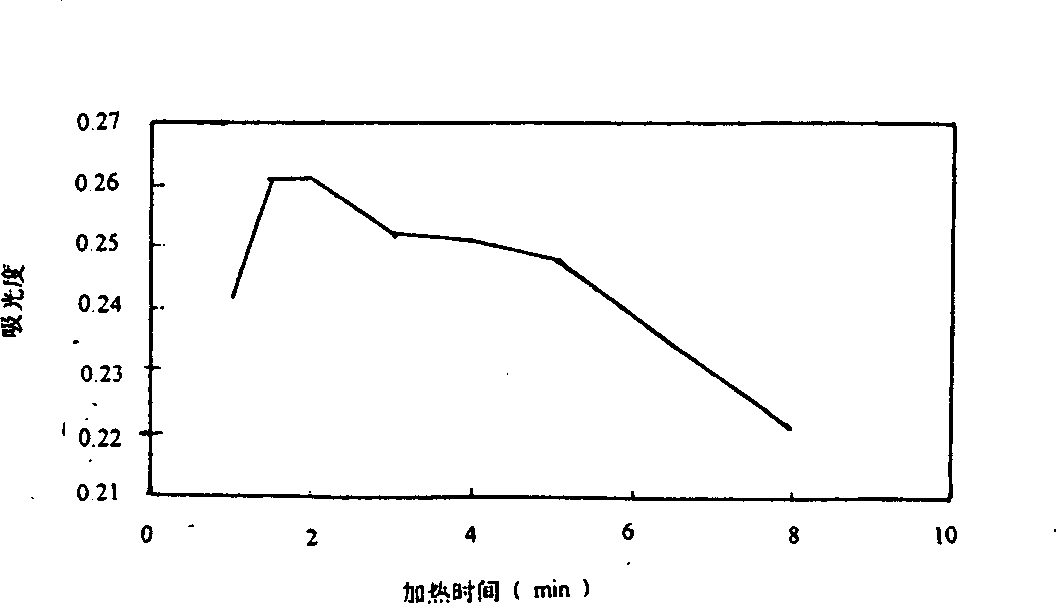

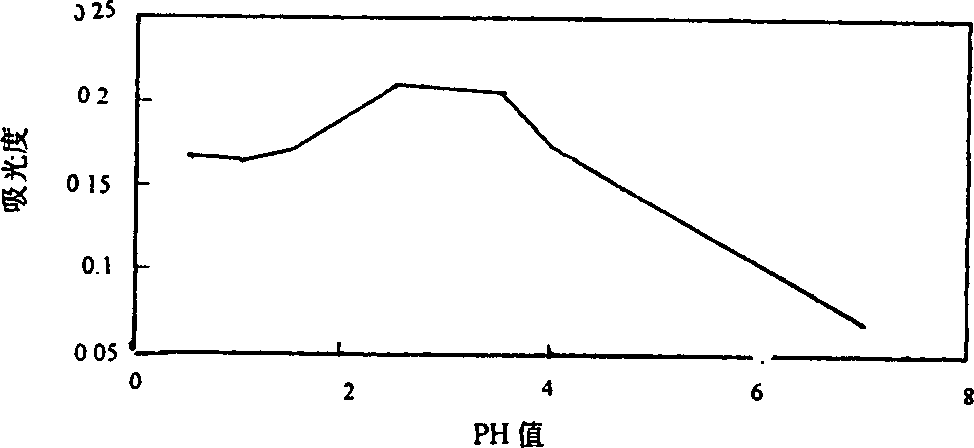

[0030] Weigh the chromogenic agent naphthaleneethylenediamine hydrochloride, p-aminobenzenesulfonamide or p-aminobenzenesulfonic acid in a mass ratio of 1:10, put them in a round bottom flask, add an appropriate amount of organic solvent acetonitrile, or use After the organic solvent that can dissolve the color developer but not PVC is completely dissolved, add carrier PVC (polyethylene resin, particle size 80-100 mesh) 10 times the amount of the color developer, shake well, and use a rotary evaporator. treatment, and at the same time pass nitrogen gas to make the solvent evaporate to dryness, become a uniform solid color developer, and store it airtight, and can be stored for a long time, which is consistent with the stability of pure reagents.

[0031] The following test has been carried out on the proportioning of the chromogenic agent: take 5 mL of 2 μg / mL nitrite standard solution in a colorimetric tube, add the chromogenic agent according to the proportioning data in the ...

Embodiment 2

[0038] Take about 1g of the nitrite sample to be tested in a graduated 15mL test tube, chop the sample with a chopping stick, add water to the 5mL scale, shake well, add 1mL of 0.5mol / L NaOH solution, shake and mix well, then add 120g / L NaOH solution lm w 4 7H 2 After 1mL of O solution was oscillated, heat it on an alcohol lamp for 1.5min, keep it from boiling during heating, and mix it by oscillating from time to time, add 2mL of ammonium acetate buffer solution, add water to the scale of 15mL, mix well, and add solid to 1mL Add hydrochloric acid (1+1) to the 0.5mL mark line in a plastic centrifuge tube with 0.02g of chromogenic agent, then filter the above mixed solution into 1mL of the plastic centrifuge tube, close it tightly, shake it for 2min, and mix with the pre-made A good standard color scale can be used to measure its content by visual colorimetric comparison.

[0039] During the pretreatment of the sample to be tested, the concentration of NaOH is controlled at 0...

Embodiment 3

[0066] The experimental conditions are the same as in Example 2, the added solid chromogenic dose is still 0.02g, and the liquid to be tested is visually compared with a spectrophotometer and a standard color scale, and the result is an absorbance value of 0.027, and its content is 0.73 μg , the standard color scale is magenta. The g / kg value can be obtained from the standard color scale.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com