Carbon dot-modified carbon nitride/stannic oxide composite photocatalyst, and preparation method and application thereof

A technology of tin dioxide and carbon nitride, which is applied in the field of photocatalytic materials, can solve the problems of high recombination rate, low toxicity and high stability of photogenerated carriers, and achieve the effects of improving catalytic ability, inhibiting recombination, and improving photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. First add 5g of guanidine hydrochloride into a covered alumina crucible, put it into a muffle furnace, heat up to 550°C for 4 hours at a rate of 2°C / min in an air environment, anneal to room temperature, and grind to obtain carbon nitride Powder: Dissolve 2.1g of tin tetrachloride pentahydrate in 70mL of ultrapure water, transfer to stainless steel lined with polytetrafluoroethylene after ultrasonic heating, heat in an oven at 180°C, wash several times with deionized water and ethanol, and collect The white product is SnO 2 .

[0037] 2. Dissolve 3g of citric acid and 1g of urea in 10mL of ultrapure water for ultrasonication, transfer to a polytetrafluoroethylene-lined stainless steel reactor, heat in an oven at 180°C, cool to room temperature, centrifuge at 10,000r / min for 30min, and collect The clear solution was dissolved in deionized water to obtain CDs stock solution.

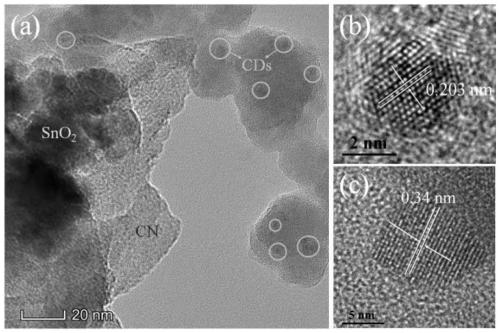

[0038] 3. Dissolve 0.32g of carbon nitride and 0.08g of tin dioxide in ethanol solution, ul...

Embodiment 2

[0041] 1. First add 5.0g of guanidine hydrochloride into a covered alumina crucible, put it into a muffle furnace, heat up to 550°C for 4 hours at a heating rate of 2.5°C / min in an air environment, anneal to room temperature, and grind to obtain Carbon nitride powder; Dissolve 2.3g of tin tetrachloride pentahydrate in 70mL of ultrapure water, and transfer it into a polytetrafluoroethylene-lined muffle furnace after ultrasonication for 1h. After heating at 180°C, use deionized water and ethanol centrifuged several times, the collected white product is SnO 2 .

[0042] 2. Dissolve 2.5g of citric acid and 1.3g of urea in 10mL of ultrapure water for ultrasonication, transfer to a polytetrafluoroethylene inner stainless steel reaction kettle, heat in an oven at 180°C, cool to room temperature, centrifuge at 10,000r / min for 30min, and collect The supernatant was dissolved in 100 mL deionized water to obtain CDs stock solution.

[0043] 3. Dissolve 0.32g of carbon nitride and 0.08g...

Embodiment 3

[0046] 1. First add 4.5g of guanidine hydrochloride into a covered alumina crucible, put it into a muffle furnace, heat up to 550°C for 4 hours at a rate of 2°C / min in an air environment, anneal to room temperature, and grind to obtain nitriding Carbon powder: Dissolve 2.1g of tin tetrachloride pentahydrate in 70mL of ultrapure water, transfer to a Teflon-lined muffle furnace after ultrasonication for 1h, heat in an oven at 180°C, and centrifuge with deionized water and ethanol After washing several times, the white product is collected as SnO 2 .

[0047] 2. Dissolve 2.8g of citric acid and 1.2g of urea in 10mL of ultrapure water and sonicate for 1h, then transfer to a polytetrafluoroethylene-lined stainless steel reactor, heat in an oven at 180°C, cool to room temperature, and centrifuge at 10,000r / min for 30min , the collected supernatant was dissolved in 100 mL deionized water to obtain CDs stock solution.

[0048] 3. Dissolve 0.32g of carbon nitride and 0.08g of tin dio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com