Aza-fused conjugated trapezoidal polymer and preparation method thereof, and application of aza-fused conjugated trapezoidal polymer in catalysis of water decomposition under visible light

A technology of polymer and polymerization reaction, applied in the direction of organic compound/hydride/coordination complex catalyst, chemical instrument and method, physical/chemical process catalyst, etc., can solve unfavorable photocatalytic industrial application, no degradation phenomenon, improve Cost and other issues, to achieve the effect of short synthesis time, low cost, and short time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

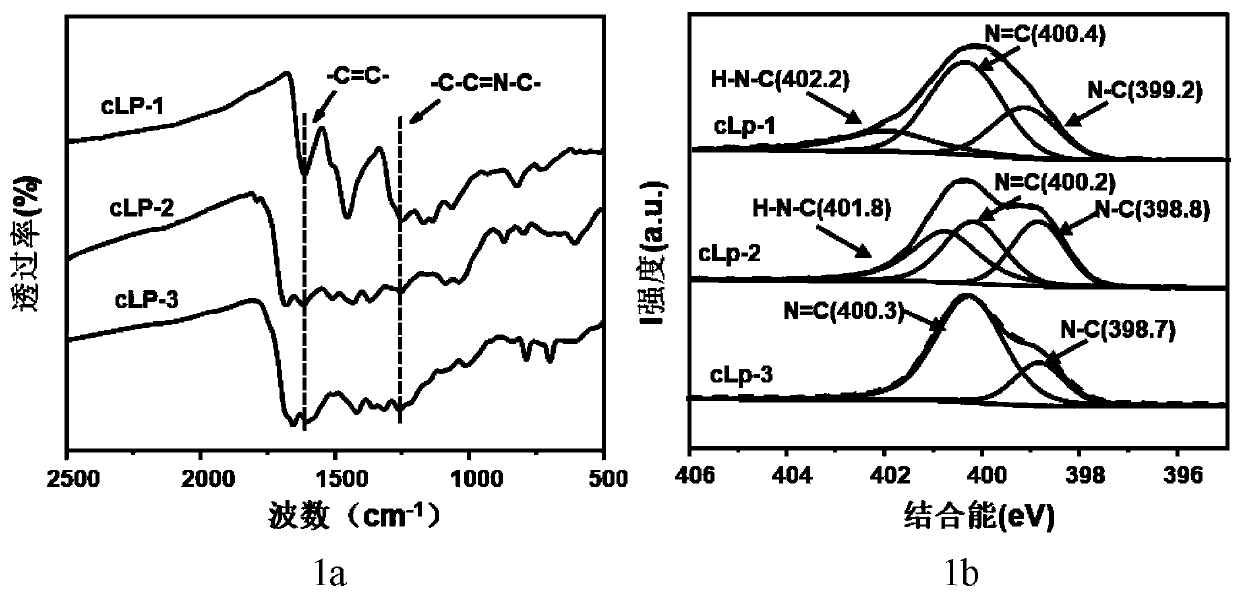

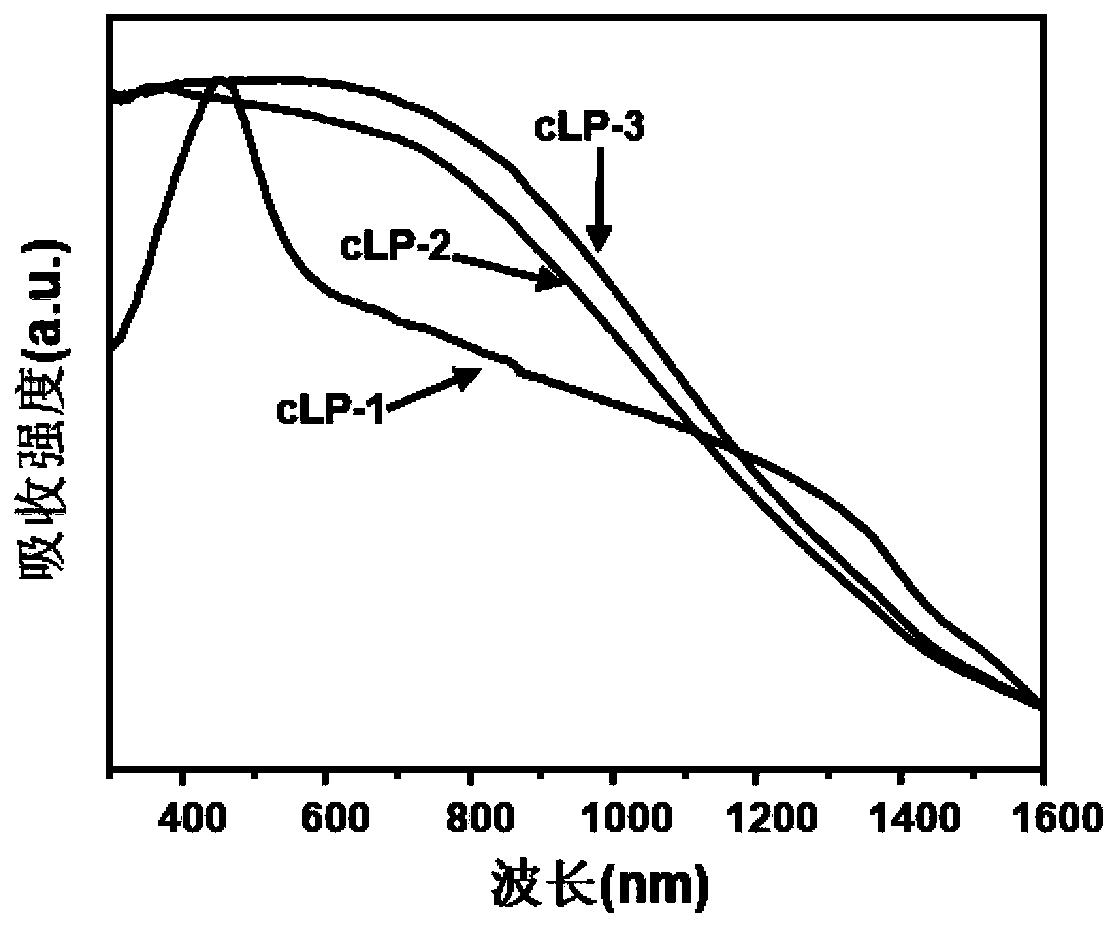

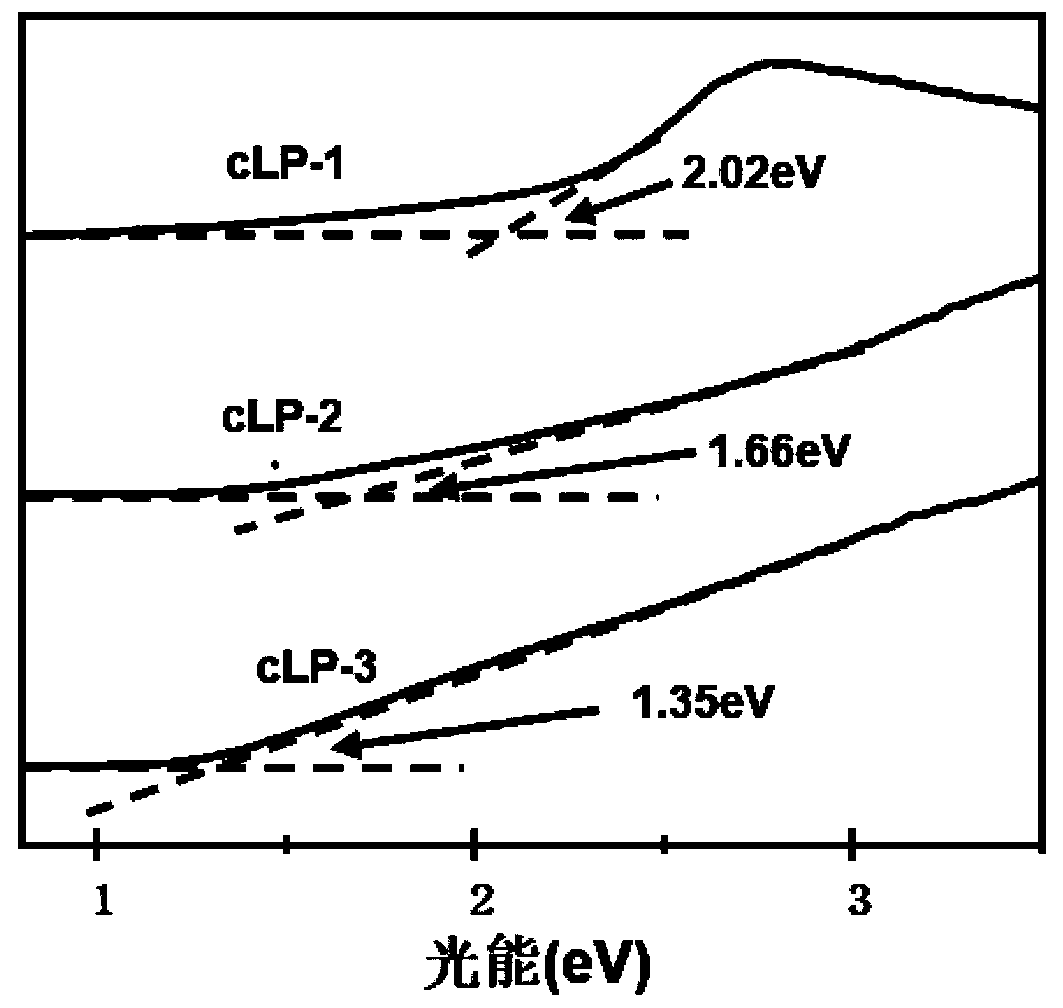

[0075] Add 100 grams of polyphosphoric acid (PAA) to a 150 ml two-neck flask equipped with a nitrogen inlet and outlet, control the nitrogen flow rate to be 30 ml / min to blow air into the polyphosphoric acid, and heat the polyphosphoric acid at 120 ° C 24 hours to completely deoxidize polyphosphoric acid. Then the temperature of the system was lowered to 50°C, and 568 mg of 1,2,4,5-benzenetetramine tetrahydrochloride was quickly added to the deoxygenated polyphosphoric acid in a nitrogen atmosphere, while the system was heated to 120°C for 12 hours To remove all the hydrogen chloride in 1,2,4,5-benzenetetramine tetrahydrochloride. Then, 282 mg of 2,5-dihydroxy-1,4-benzoquinone was added to the mixture at 110°C, and the mixture was slowly heated (with a heating rate of 4°C / min) to 180°C and kept for 12 hours. After cooling the obtained viscous solution to room temperature, transfer it to a 500 ml beaker, and add 400 ml of water to the beaker, stir vigorously so that polyphosph...

Embodiment 2

[0078] Add 1 g of 1,2,4,5-benzenetetramine tetrahydrochloride and 500 mg of piperazine-2,3,5,6-tetraketone into a 200-ml round-bottomed flask under an inert atmosphere, and then place the round-bottomed The flask was placed in an ice bath (temperature controlled at 0°C). 80 milliliters of N-methylpyrrolidone (NMP) was deoxidized, then mixed with 0.5 milliliters of sulfuric acid, and the mixed solution was slowly added dropwise to the above-mentioned round bottom flask. Then the reaction device was raised to room temperature, and after stirring for 2 hours, an oil bath was used instead of an ice-water bath and the entire reaction device was heated to 180°C. After continuous reaction for 8 hours, the heating was stopped and the device was cooled to room temperature. Add water to quench the reaction in the round-bottomed flask, and the suspension after the reaction uses polytetrafluoroethylene (PTFE, 0.22 micron) organic filter membrane to carry out suction filtration to obtain t...

Embodiment 3

[0081] Add 1 g of 1,2,4,5-benzenetetramine tetrahydrochloride and 922 mg of pyrene-4,5,9,10-tetraketone into a 200-ml round-bottomed flask under an inert atmosphere, and then place the round-bottomed flask Place in an ice bath (temperature controlled at 0°C). 80 milliliters of N-methylpyrrolidone (NMP) was deoxidized, then mixed with 0.5 milliliters of sulfuric acid, and the mixed solution was slowly added dropwise to the above-mentioned round bottom flask. Then the reaction device was raised to room temperature, and after stirring for 2 hours, an oil bath was used instead of an ice-water bath and the entire reaction device was heated to 180°C. After continuous reaction for 8 hours, the heating was stopped and the device was cooled to room temperature. Add water to the round-bottomed flask to quench the reaction, and the suspension after the reaction is suction-filtered with a polytetrafluoroethylene (PTFE, 0.22 micron) organic filter membrane to obtain a black solid product, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com