Two-aqueous-phase extraction method of polygonatum sibiricum polysaccharide

A Polygonatum polysaccharide, two-phase technology, applied in the field of two-phase extraction of Polygonatum polysaccharide, can solve the problems of high cost, low efficiency, and low product purity, and achieve the effect of low cost, high efficiency, and high purity of the separated product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

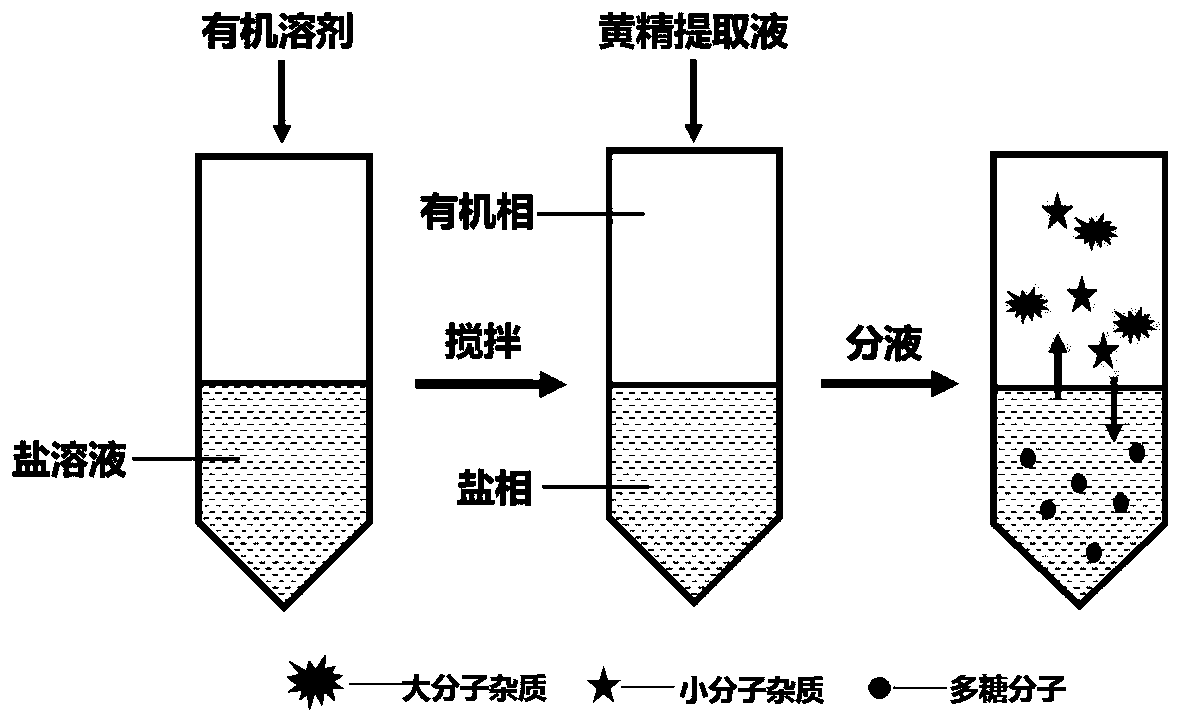

[0027] (1) After the Polygonatum raw material is pulverized, pass through a 50-mesh sieve, use petroleum ether to degrease and dry, and extract Polygonatum Polysaccharide with water to obtain a concentration of 50g / L Polygonatum polysaccharide extract, wherein the extraction temperature is 80°C, and the solid-to-liquid ratio is 1: 20, stirring rate 400r / min, extraction time 2h.

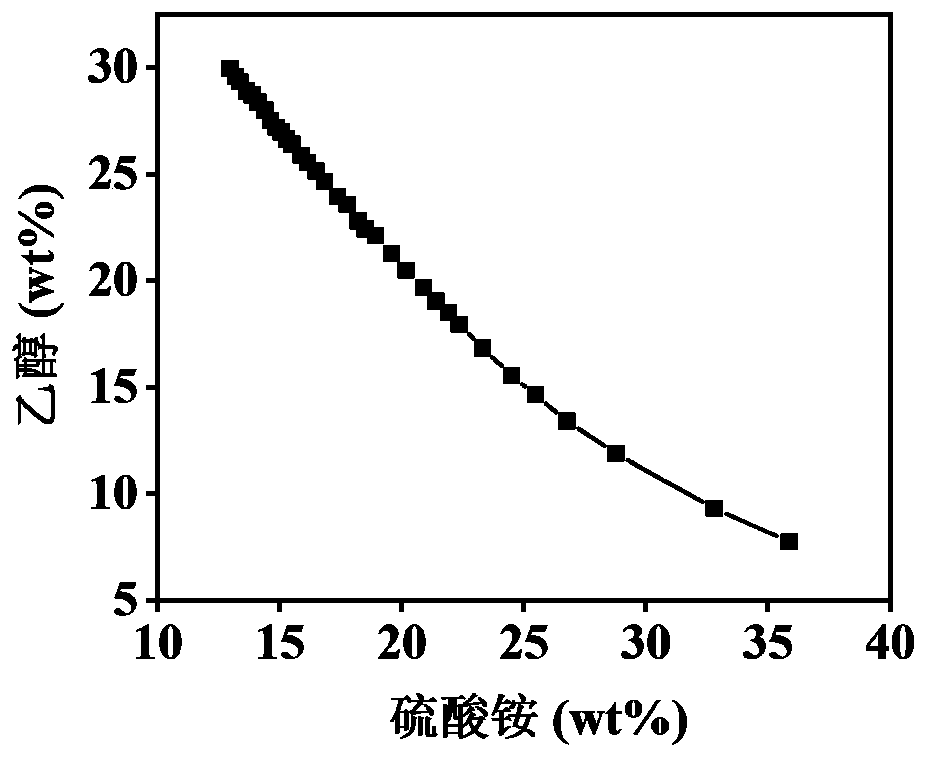

[0028] (2) Adding 49g mass fraction to 40.8% ammonium sulfate aqueous solution in 20g dehydrated ethanol obtains a two-phase extraction system, and the ethanol-ammonium sulfate two-phase phase diagram is as follows figure 2 shown.

[0029] (3) Take 31g Polygonatum polysaccharide extract and add it into the ethanol-ammonium sulfate two-phase extraction system, the extraction temperature is 40°C, the stirring speed is 400r / min, and the extraction time is 10min. After the extraction, the liquid was separated and the lower phase was kept.

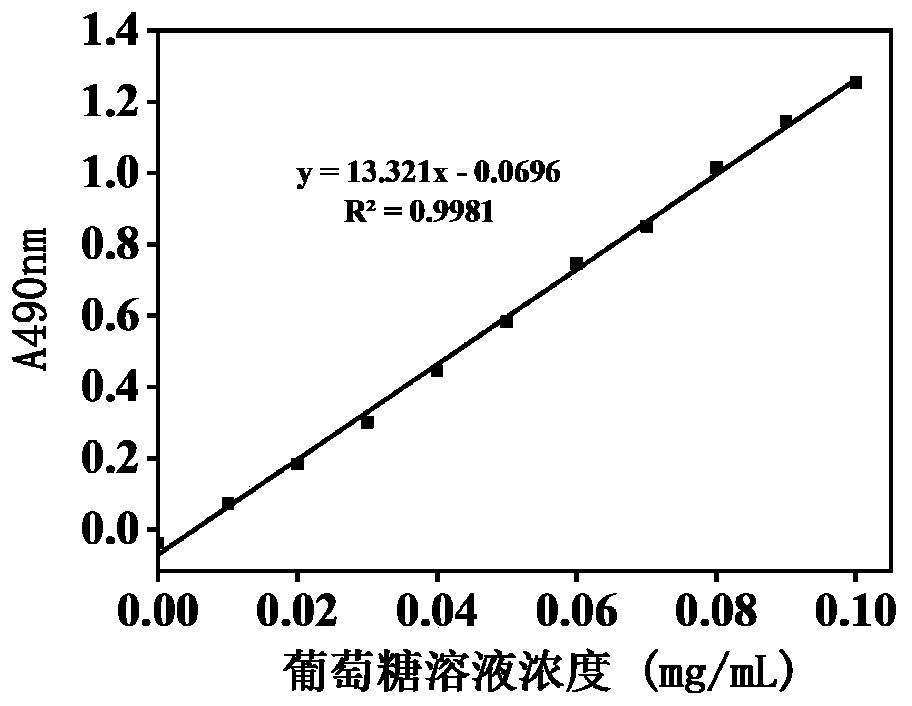

[0030] (4) Add 5 times of absolute ethanol to the volume of th...

specific Embodiment approach 2

[0033] (1) After the Polygonatum raw material is pulverized, pass through a 50-mesh sieve, use petroleum ether to degrease and dry, and extract Polygonatum Polysaccharide with water to obtain a concentration of 50g / L Polygonatum polysaccharide extract, wherein the extraction temperature is 80°C, and the solid-to-liquid ratio is 1: 20, stirring rate 400r / min, extraction time 2h.

[0034] (2) Adding 46g mass fraction to 39.13% ammonium sulfate aqueous solution in 25g dehydrated ethanol, obtains two-phase extraction system, and ethanol-ammonium sulfate two-phase phase diagram is as follows figure 2 shown.

[0035] (3) Take 29g Polygonatum polysaccharide extract and add it into the ethanol-ammonium sulfate two-phase extraction system, the extraction temperature is 40°C, the stirring speed is 400r / min, and the extraction time is 10min. After the extraction, the liquid was separated and the lower phase was kept.

[0036] (4) Add 5 times of absolute ethanol to the volume of the tw...

specific Embodiment 3

[0039] Embodiment 3 differs from Embodiment 1 in that the Polygonatum polysaccharide extract is used in an amount of 26 g, and the amount of absolute ethanol is 25 g, and the rest of the treatment and processing methods are the same as in Embodiment 1. The yield of Polygonatum Polysaccharide obtained is 34.8%, and the purity is 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com