Flexible ferrous phosphide/carbon nanofiber membrane, and preparation method and application thereof

A technology of carbon nanofibers and iron phosphide, applied in the fields of fiber chemical characteristics, rayon manufacturing, electrochemical generators, etc., can solve problems such as shedding, unstable electrode capacity effects, etc., to enhance electrical conductivity and maintain structural integrity , the effect of simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of iron phytate nanoparticles. The preparation of ferric phytate nanoparticles includes two steps of synthesis and purification.

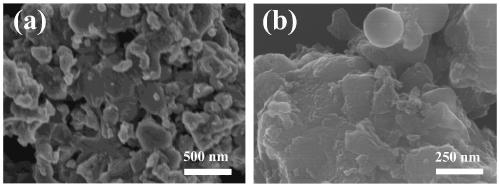

[0037] Dissolve 1.0 g of phytic acid in 10 mL of water, adjust the pH to 6 with concentrated ammonia water as solution A. Weigh 0.944g FeCl 3, 1 g of urea and 0.2 g of surfactant cetyltrimethylammonium bromide (CTAB) were dissolved in 5 mL of deionized water as solution B. Slowly add solution B to solution A drop by drop, resulting in white precipitates, which are centrifuged with deionized water and collected. White Fe-based precursor powder (iron phytate) obtained after drying. like figure 1 As shown, the size of iron phytate nanoparticles is about 200-500nm.

Embodiment 2

[0039] Preparation of iron phytate nanoparticles. The preparation of ferric phytate nanoparticles includes two steps of synthesis and purification.

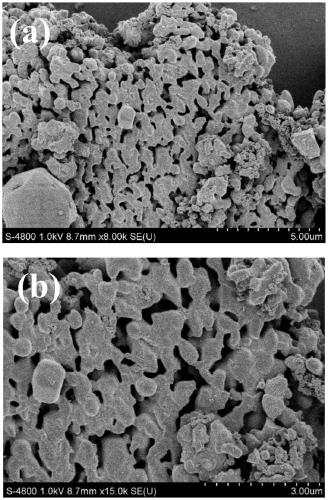

[0040] Dissolve 10.0 g of phytic acid in 10 mL of water, adjust the pH to 5 with concentrated ammonia water as A solution. Weigh 1g FeCl 3 , 1 g of ammonia water and 0.2 g of surfactant polyvinylpyrrolidone were dissolved in 5 mL of deionized water as solution B. Slowly add solution B to solution A drop by drop, resulting in white precipitates, which are centrifuged with deionized water and collected. White Fe-based precursor powder (iron phytate) obtained after drying. like figure 2 As shown in a, the size of iron phytate nanoparticles is about 500-1000 nm.

Embodiment 3

[0042] Preparation of iron phytate nanoparticles. The preparation of ferric phytate nanoparticles includes two steps of synthesis and purification.

[0043] Dissolve 5.0 g of phytic acid in 10 mL of water, adjust the pH to 4 with concentrated ammonia water as solution A. Weigh 1g FeCl 3 , 1 g of urea and 0.2 g of surfactant sodium dodecylbenzene sulfonate were dissolved in 5 mL of deionized water as solution B. Slowly add solution B to solution A drop by drop, resulting in white precipitates, which are centrifuged with deionized water and collected. White Fe-based precursor powder (iron phytate) obtained after drying. like figure 2 As shown in b, the size of iron phytate nanoparticles is about 500-1000nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com