Gel polymer electrolyte doped with modified particles, preparation method and application thereof

A technology of gel polymers and modified particles, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of not giving full play to inorganic-organic compounding, low concentration range of inorganic particle compounding, easy aggregation and segregation, etc. Achieve the effect of enhancing electrochemical performance, good electrochemical performance and mechanical performance, and improving chain segment motion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The dried polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP) and lithium perchlorate were dissolved in a mixed solution of PC and acetone in proportion, and magnetically stirred at 50°C. The mass ratio of polyvinylidene fluoride-hexafluoropropylene, lithium perchlorate, PC and acetone is 9:3:20:68.

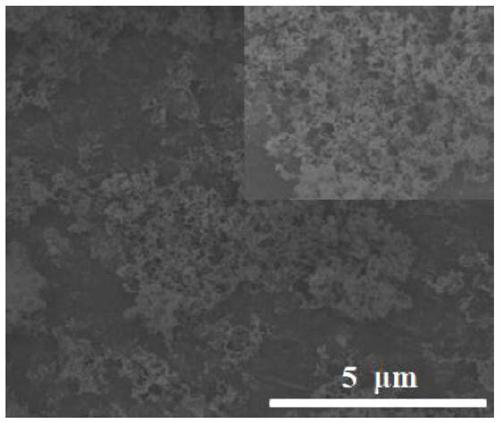

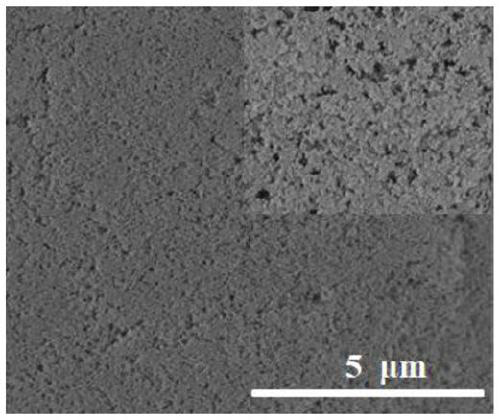

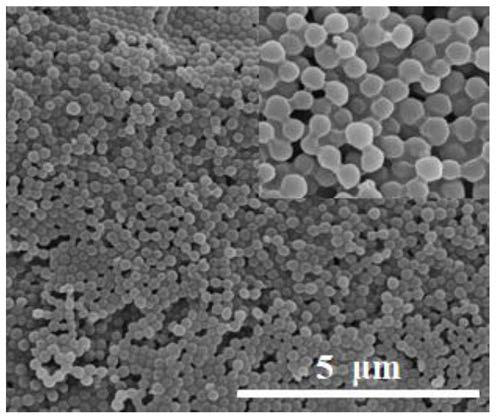

[0056] Add different concentrations of modified silica SiO to the solution 2 -PMMA-2, the sum of the mass of polyvinylidene fluoride-hexafluoropropylene and lithium perchlorate is 100%, doped modified silica SiO 2 - The content of PMMA-2 is 1%, 2%, 3%, 4%, 5%, 7%, 10%, 15% in sequence, and the stirring is continued for 2 hours to form a viscous sol. Subsequently, the sol was poured into a polytetrafluoroethylene mold, and dried in an oven at 60° C. for 12 hours to obtain a gel polymer electrolyte.

[0057] Modified silica SiO 2 -Modified silicon dioxide SiO in the preparation method of -PMMA-2 and comparative example 2 2 -The preparation method of PMMA-1 is the same...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com