CeO2-based electrocatalytic oxygen production catalyst and preparation method and application thereof

An oxygen catalyst and electrocatalysis technology, applied in the field of electrocatalysis, can solve the problems of no catalytic activity or weak catalytic activity, and achieve the effects of improved electrocatalytic oxygen production performance, obvious economic benefits, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

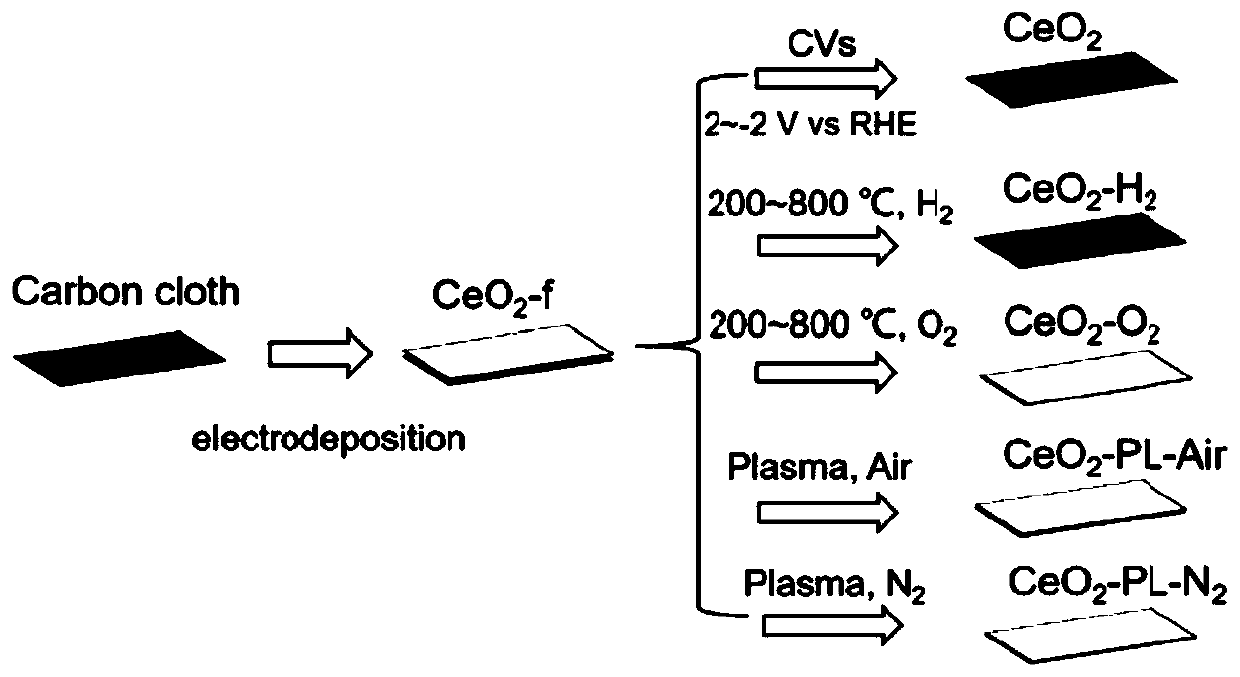

[0040] CeO 2 The preparation of -f comprises the steps:

[0041] (1) Ultrasonic rinse the commercially available carbon cloth substrate in a mixed solution (30% wt) of sulfuric acid and nitric acid (volume ratio 1:1) for 2 hours. Air dry naturally;

[0042] (2) After the washed carbon cloth is made into an electrode, it is soaked in CeO 2 precursor solution, heated the solution to 70°C and applied a constant current of 0.25 mA / cm2 for 20 minutes, CeO 2 Will be generated in situ on the carbon cloth surface.

[0043] The CeO 2 The precursor solution is a mixed solution of 2 mmol cerium nitrate and 10 mmol sodium chloride.

Embodiment 2

[0045] a CeO 2 Based electrocatalytic oxygen generation catalyst, its preparation method comprises the steps:

[0046] (1) According to the method of embodiment 1, CeO 2 Fresh samples were deposited onto the carbon cloth surface to obtain CeO 2 -f;

[0047] (2) A three-electrode system is adopted, the reference electrode is silver / silver chloride, the counter electrode is platinum wire, fresh CeO 2 (CeO 2 -f) as a working electrode, the electrolyte is 1M KOH solution;

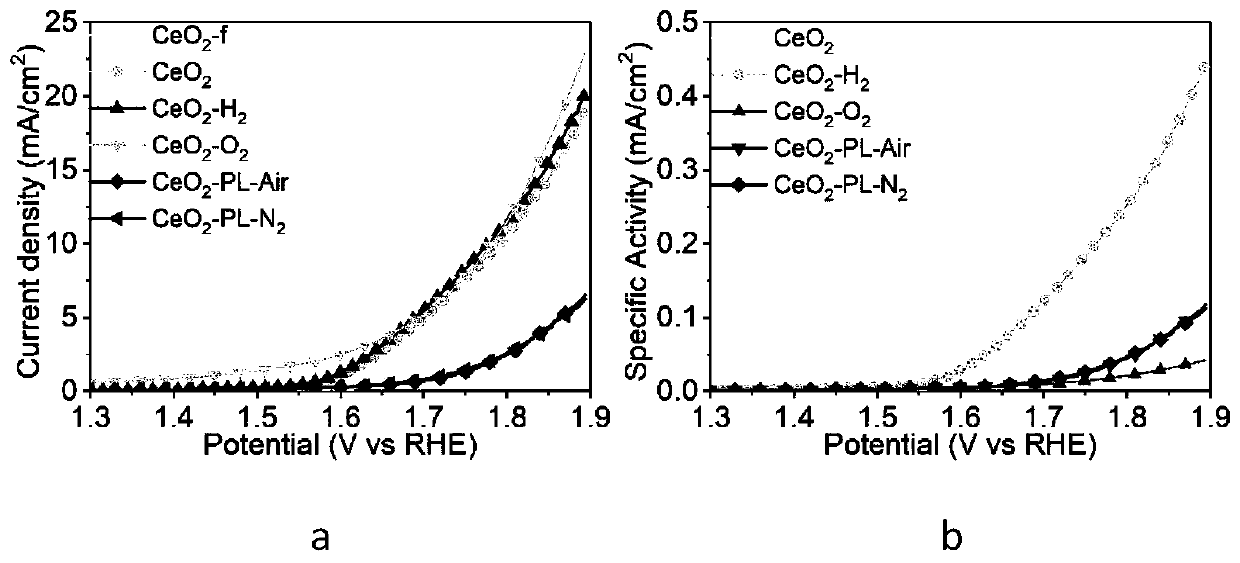

[0048] (3) Using the electrochemical workstation, the CeO 2 -f 30 cyclic voltammetry (CV) scans in the voltage range from 1 to −0.5 V versus the reversible hydrogen electrode to produce CeO 2 Electrocatalytic oxygen generation catalyst;

[0049] (4) CeO 2 The electrocatalytic oxygen generation catalyst was taken out from the solution and rinsed with ultrapure water several times, then placed in the air to dry naturally, named CeO 2 .

Embodiment 3

[0051] a CeO 2 Based electrocatalytic oxygen generation catalyst, its preparation method comprises the steps:

[0052] (1) According to the method of embodiment 1, CeO 2 Fresh samples were deposited onto the carbon cloth surface to obtain CeO 2 -f;

[0053] (2) CeO 2 -f is placed in the quartz tube of the tube furnace, and 5% hydrogen / argon is introduced into the quartz tube for 30 minutes to remove the air in the quartz tube, so that the quartz tube is filled with 5% hydrogen / argon;

[0054] (3) Continue to feed 5% hydrogen / argon, and at the same time raise the temperature to 500°C at a rate of 10°C / min and keep it warm for 2 hours;

[0055] (4) After the heat preservation is over, the sample in the quartz tube is naturally cooled to room temperature with the furnace, and the ventilation is closed to take out the sample, which is named CeO 2 -H 2 .

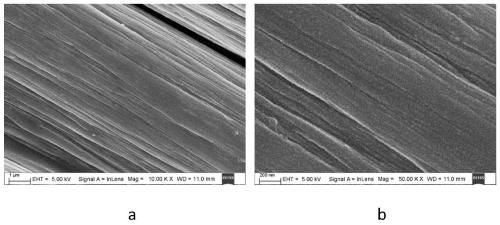

[0056] The prepared CeO 2 -H 2 Planar structures under different magnification electron microscopes such as image 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com