Method for preparing green catalyst from biomass tar and application

A biomass and catalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve uncontrollable problems and achieve the effect of improving selectivity, high oxygen content, and best catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] preparation method according to claim 1, is characterized in that, the preparation process of carbon carrier is: 20g carbon precursor biomass tar is dissolved in 100ml absolute ethanol, and activator (K 2 FeO 4 , KOH) aqueous solution was added dropwise to the biomass tar solution, stirred in a 60°C water bath until a uniform solid was obtained, and then dried for 12h to obtain a solid mixture. The solid mixture was ground into uniform fine powder, placed in a tube furnace, and calcined for 2 h at different temperature (400-1000°C) at different heating rates (1-10°C / min) in a nitrogen atmosphere. After cooling to room temperature, wash the sample. Finally, vacuum drying at 100 °C for 12 h was performed to prepare a low-cost carbon carrier.

[0028] In the above preparation method, the catalyst is composed of a carrier and a nickel salt.

[0029]In the above preparation method, the concentration of potassium in the two activators in step (1) is the same and is 0.05-0....

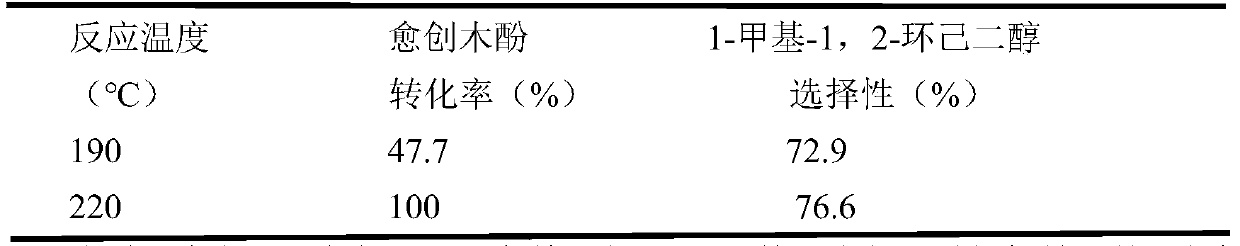

Embodiment 1

[0044] (1) Preparation of carbon carrier with biomass tar: Weigh 20g of carbon precursor biomass tar and dissolve it in 100ml of absolute ethanol, then add 100ml 0.2mol / L activator KOH aqueous solution dropwise to the biomass tar ethanol solution, at 60 °C in a water bath environment for 8 h until a uniform solid was obtained, and then dried at 100 °C for 12 h to obtain a solid mixture. Grind the solid mixture into a uniform fine powder, put it in a tube furnace, raise the temperature to 800°C at 1°C / min in a nitrogen atmosphere, and roast for 2h. After cooling to room temperature, the sample was washed with HCl (1M, 100ML) and refluxed in a water bath for 10 hours, then washed twice with deionized water and washed three times with ethanol. Finally, the low-cost carbon support was prepared by vacuum drying at 100 °C for 12 h.

[0045] The preparation of catalyst, loading mass fraction is 10% metallic single substance nickel: with 1.1010g Ni (NO 3 ) 2 ·6H 2 O was dissolved ...

Embodiment 2

[0058] (1) Preparation of carbon carrier from biomass tar: Weigh 20g of carbon precursor biotar and dissolve it in 100ml of absolute ethanol, then add 100ml of 0.1mol / L activator K 2 FeO 4 The aqueous solution was added dropwise to the biotar solution, stirred in a water bath environment at 60°C for 8h until a uniform solid was obtained, and then dried at 100°C for 12h to obtain a solid mixture. Grind the solid mixture into a uniform fine powder, put it in a tube furnace, raise the temperature to 400°C at 1°C / min in a nitrogen atmosphere, and bake for 2h. After cooling to room temperature, the sample was washed with HCl (1mol / L, 100mL) and condensed and refluxed in a water bath for 10h, then washed twice with deionized water, and washed three times with ethanol. Finally, the low-cost carbon support was prepared by vacuum drying at 100 °C for 12 h.

[0059] The preparation of catalyst: loading mass fraction is 10% metallic single substance nickel, 1.1010g Ni (NO 3 ) 2 ·6H ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com