Method for preparing porous gamma-Al2O3 nano material by taking eutectic solvent as solvent and template agent

A technology of deep eutectic solvents and nanomaterials, applied in the direction of nanotechnology, alumina/aluminum hydroxide, etc., can solve the problems of difficult control of product size and shape, difficulty in industrialization, serious environmental pollution, etc., and achieve good crystal form, Inexpensive, high adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The first step preparation of deep eutectic solvent

[0032] Mix and stir 139.62g choline chloride and 184.18g glycerol in a water bath at 80°C for half an hour to form a deep eutectic solvent.

[0033] The second step is to mix the reactants

[0034] 2.62g of AlCl 3 ·6H 2 O was added in 35g of deep eutectic solvent, stirred for 1 hour under 80°C water bath condition, then added 50ml of ammonium carbonate solution with a concentration of 0.645mol / L under 45°C water bath condition and stirred for 1 hour to prepare the reaction mixture, namely by low Eutectic solvent: AlCl 3 ·6H 2 Molar ratio of O: ammonium carbonate solution = 30:1:3 ratio.

[0035] The third step crystallization

[0036] The reaction mixture prepared in the second step was crystallized at 150°C for 30 hours.

[0037] Step 4 Wash and dry

[0038] The reaction mixture after crystallization in the third step was centrifuged and washed several times with deionized water and ethanol until the pH valu...

Embodiment 2

[0043] Operation process is except following difference, all the other are with embodiment 1:

[0044] The second step is to mix the reactants

[0045] 2.62g of AlCl 3 ·6H 2 O was added in 35g deep eutectic solvent, stirred under 80 DEG C of water bath conditions for 1 hour, then added 35 ml of ammonium carbonate solution with a concentration of 0.92mol / L under 45 DEG C of water bath conditions and stirred for 1 hour to prepare the reaction mixture, namely by low Eutectic solvent: AlCl 3 ·6H 2 Molar ratio of O: ammonium carbonate solution = 30:1:3 ratio.

[0046] The third step crystallization

[0047] The reaction mixture prepared in the second step was crystallized at 180° C. for 30 hours.

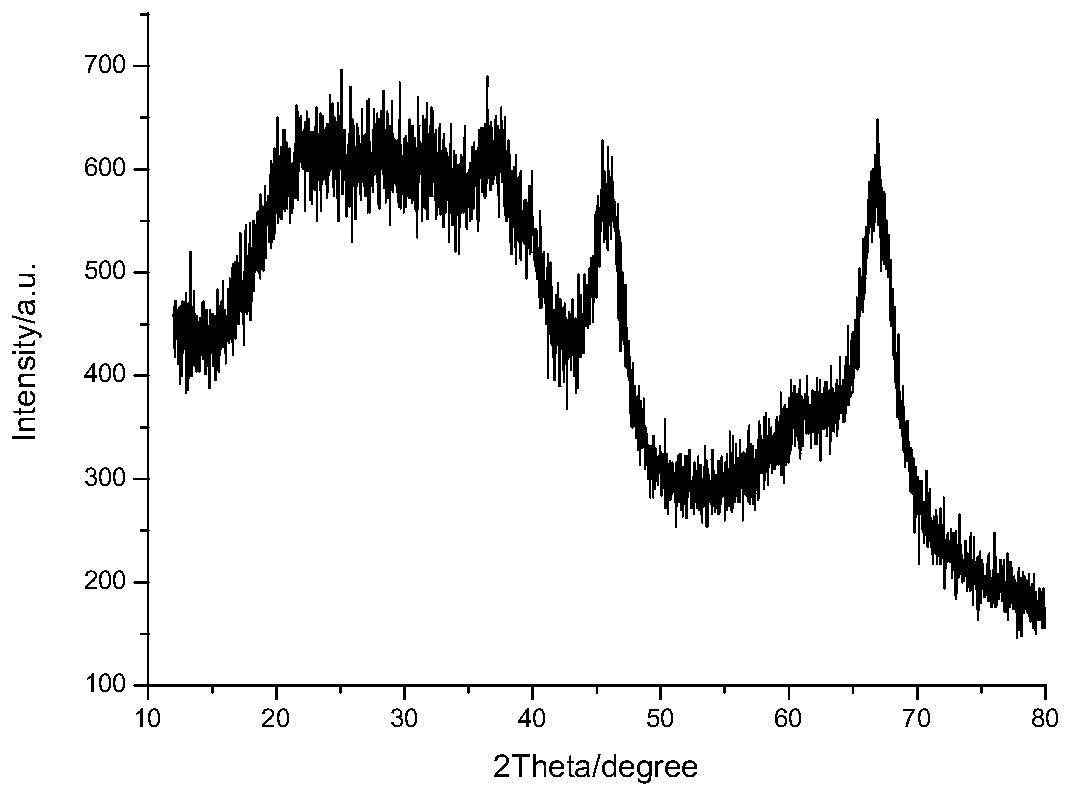

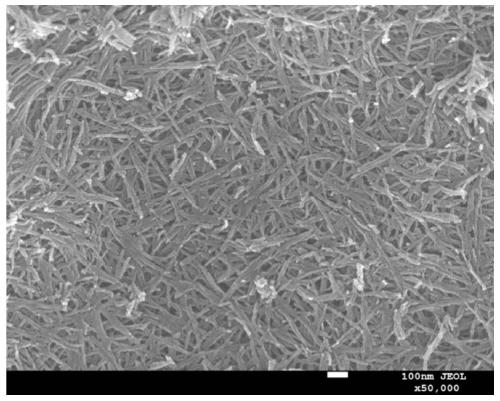

[0048] The test and characterization of the prepared sample are the same as in Example 1, and it can be seen from the XRD analysis that the obtained product is γ-Al with good crystal form 2 o 3 . According to the test results of the field emission scanning electron microscope (S...

Embodiment 3

[0050] Operation process is except following difference, all the other are with embodiment 1;

[0051] The first step preparation of deep eutectic solvent

[0052] Mix and stir 139.62g choline chloride and 120.12g urea in a water bath at 80°C for half an hour to form a deep eutectic solvent.

[0053] The second step is to mix the reactants

[0054] Add 35ml of deionized water to 35g of deep eutectic solvent, stir for 30 minutes under 80°C water bath, then add 2.62g of AlCl 3 ·6H 2 O was added into the mixed solution, and the stirring was continued for 1 hour under the condition of 80°C water bath. Finally, add 35 ml of ammonium carbonate solution with a concentration of 0.92 mol / L and stir for 1 hour under the condition of a water bath at 45°C to obtain a reaction mixture, that is, according to the deep eutectic solvent: AlCl 3 ·6H 2 Molar ratio of O: ammonium carbonate solution = 30:1:3 ratio.

[0055] The test and characterization of the prepared sample are the same as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com