High-pore-density ultrathin-wall cordierite honeycomb ceramic carrier for TWC, and preparation method thereof

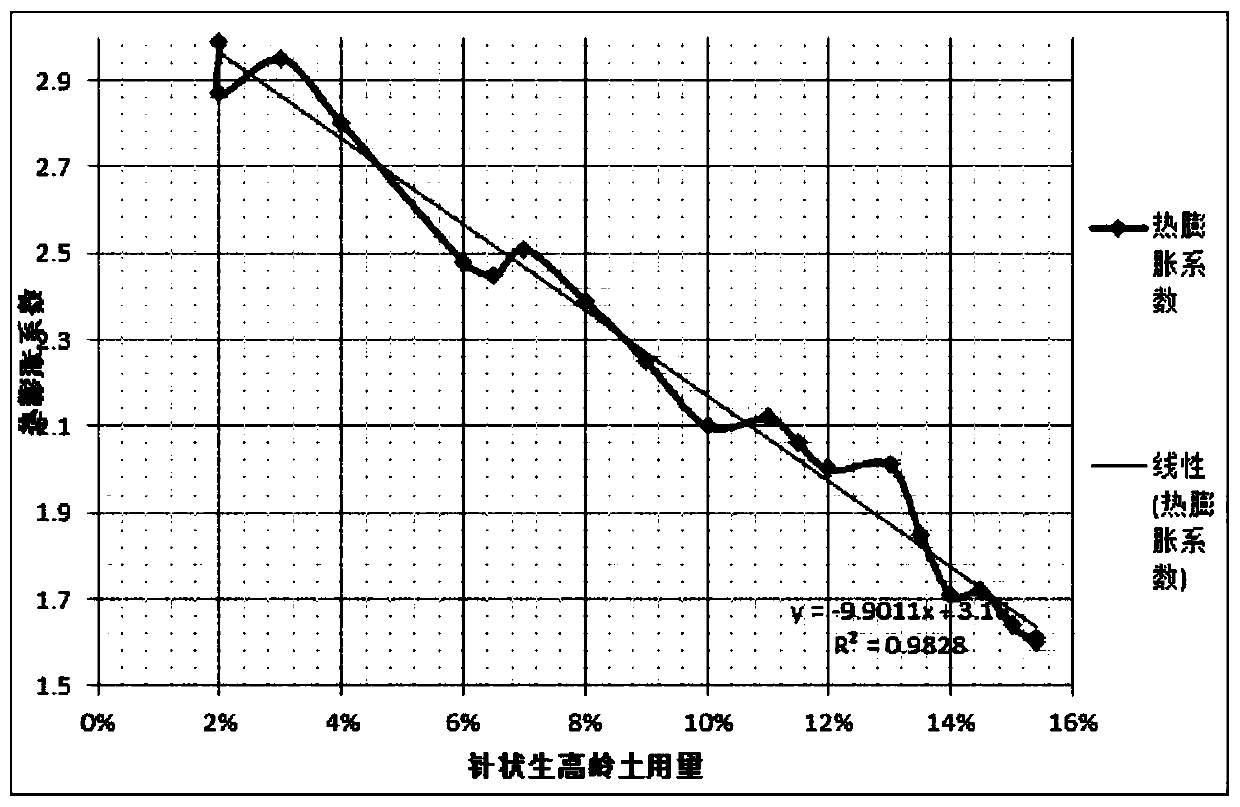

A cordierite honeycomb, ceramic carrier technology, applied in ceramic products, catalyst carriers, chemical instruments and methods, etc., can solve the problems of reducing product strength, reducing products, increasing production costs, etc., and achieving the effect of reducing CTE

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will be described in detail below in conjunction with examples, but those skilled in the art will understand that the following examples are only for illustrating the present invention, and should not be considered as limiting the scope of the present invention. Those who do not indicate the specific conditions in the examples are carried out according to the conventional conditions or the conditions suggested by the manufacturer. The reagents or instruments used were not indicated by the manufacturer, and they were all conventional products that could be purchased from the market.

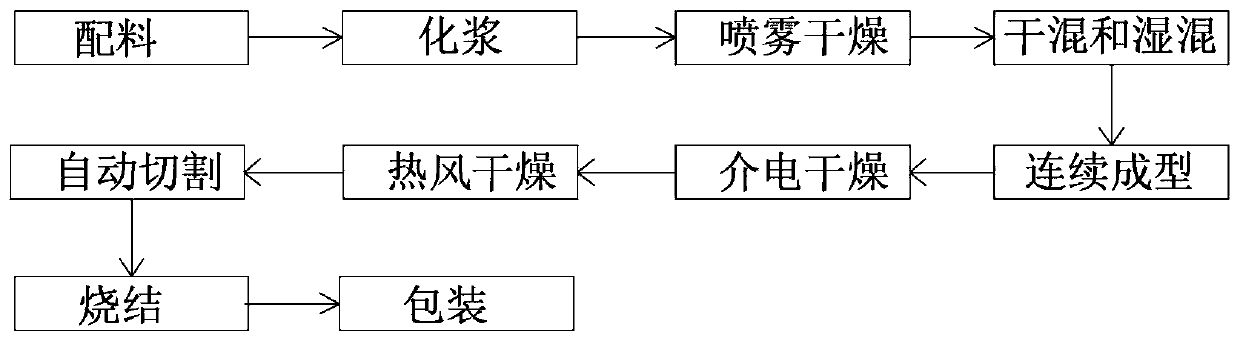

[0034]The embodiments of the present invention and specific properties are listed in Table 2, numbered E1-E25, and the comparative examples of the present invention and specific properties are listed in Table 3, numbered C1-C8. The preparation methods of the examples and the comparative examples all stir the inorganic material, the organic dispersant and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com