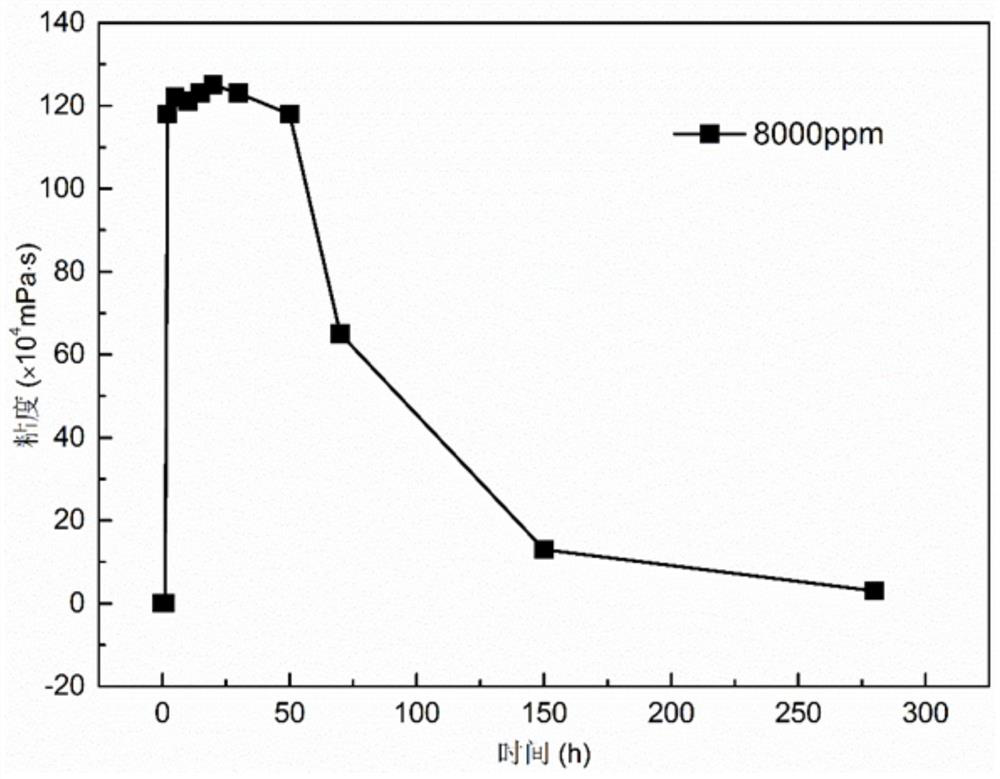

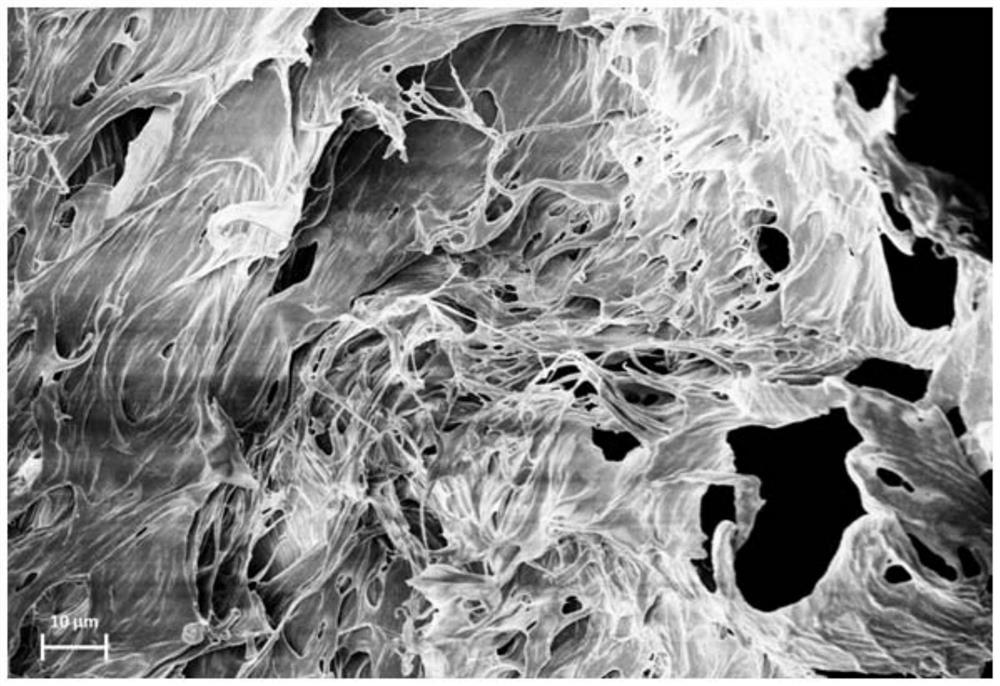

A thermally degradable hydrogel for temporary plugging under pressure

A technology of thermal degradation and hydrogel, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems that have not been proposed, the limited conditions for environment-sensitive gels to be regulated, and the inability to effectively regulate them. The effect of high viscoelasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In this embodiment, the preparation method of thermally degradable gel comprises the following steps:

[0027] Step 1. Mix 2.0g acrylamide, 1.4g 2-acrylamide-2-methylpropanesulfonic acid, 0.4g n-butyl methacrylate, 0.4g acryloyloxyethyltrimethylammonium chloride and 20g water, stirring to dissolve;

[0028] Step 2. Place the mixed solution in a constant temperature reactor, set the reaction temperature to 22°C, continue stirring and feed N 2 ;

[0029] Step 3. 0.02g reducing agent 2,2'-azobis-(methyl 2-methylpropionate) and 0.06g potassium persulfate-sodium bisulfite (both mol of potassium persulfate and sodium bisulfite) The ratio of 1:1) was added to the above mixed solution, and in a dark environment, stirring was continued at constant temperature for 1h;

[0030] Step 4. After the above reaction product is cooled to room temperature, it is placed in a mixed solution with a mass ratio of ethanol and acetone of 1:1 to wash and precipitate several times to remove un...

Embodiment 2

[0036] In this embodiment, the preparation method of thermally degradable gel comprises the following steps:

[0037] Step 1. Mix 1.0g acrylamide, 2.2g N,N'-methylenebisacrylamide, 1.4g vinyl acetate and 25g water, stir to dissolve;

[0038] Step 2. Place the mixed solution in a constant temperature reactor, set the reaction temperature to 28°C, continue stirring and feed N 2 ;

[0039] Step 3. Add 0.03g reducing agent 2,2'-azo[2-methyl-N-(2-hydroxyethyl)propionamide] and 0.56g cerium ammonium nitrate to the above mixed solution, in a dark environment , continue stirring at constant temperature for 1.5h;

[0040]Step 4. After the above reaction product is cooled to room temperature, it is placed in the mixed solution of methanol and acetone with a mass ratio of 1:1 to wash and precipitate several times to remove unreacted initiators, monomers and oligomers;

[0041] Step 5. When drying under reduced pressure until the weight is constant, a white powdery solid, i.e., a therm...

Embodiment 3

[0044] In this embodiment, the preparation method of thermally degradable gel comprises the following steps:

[0045] Step 1. Mix 3.5g acrylamide, 1.2g N,N'-methylenebisacrylamide, 1.6g acryloxyethyldimethylbenzyl ammonium chloride and 22g water, stir to dissolve;

[0046] Step 2. Place the mixed solution in a constant temperature reactor, set the reaction temperature to 32°C, continue stirring and feed N 2 ;

[0047] Step 3. Add 0.04g of reducing agent 2,2'-azobis-(methyl 2-methylpropionate) and 0.64g of ceric ammonium nitrate to the above mixed solution, and continue stirring at constant temperature for 2h in a dark environment;

[0048] Step 4. After cooling the above reaction product to room temperature, place it in acetone for washing and precipitation several times to remove unreacted initiator, monomer and oligomer;

[0049] Step 5. When drying under reduced pressure until the weight is constant, a white powdery solid, i.e., a thermally degraded polymer, is obtained; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com