Method for preparing vinylidene fluoride by resource conversion of trifluoromethane

A technology of trifluoromethane and vinylidene fluoride, which is applied in the field of resource conversion of trifluoromethane to prepare vinylidene fluoride, which can solve the problems of low yield, low selectivity of the target product vinylidene fluoride, poor thermal stability of the catalyst, etc. Low temperature, good high temperature resistance, high selectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

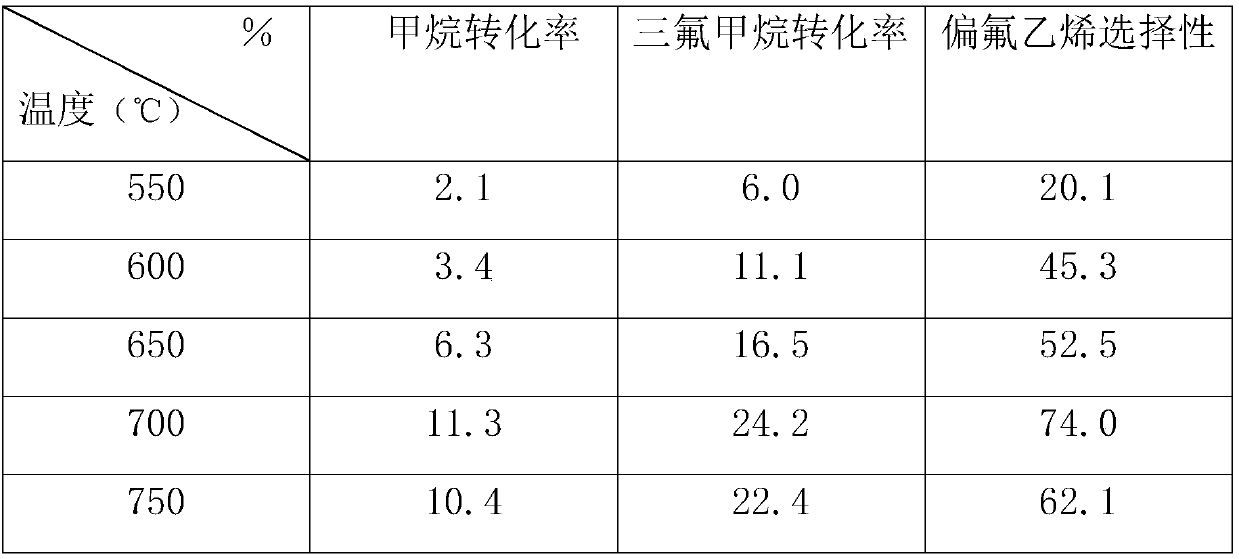

Image

Examples

Embodiment 1

[0035] Embodiment 1: catalyst preparation

[0036] Dissolve 58.8g of barium nitrate and 10.8g of lanthanum nitrate (the molar ratio of barium to lanthanum is Ba:La=9:1) in 500ml of distilled water, heat and stir in a water bath at 80°C, and slowly add diluted Hydrofluoric acid solution, keep the ratio of fluoride ion to metal ion (the sum of barium ion and lanthanum ion) at 22.5, stir vigorously while adding hydrofluoric acid solution, when the hydrofluoric acid solution is added dropwise, no white precipitate will appear , after it was filtered and washed twice with water, a white precipitate was obtained. Transfer the obtained white precipitate to a blast drying oven at 100°C for 12 hours. After the residual liquid is completely removed, place it in a muffle furnace, raise the temperature to 800°C at a rate of 2°C / min and keep it for 2 hours, then The composite barium lanthanum fluoride catalyst is obtained after self-cooling.

Embodiment 2

[0037] Embodiment 2: catalyst preparation

[0038] Dissolve 51g of barium nitrate and 21.5g of lanthanum nitrate (the molar ratio of barium to lanthanum is Ba:La=4:1) in 500ml of distilled water, heat and stir in a water bath at 80°C, and slowly add diluted hydrogen to the barium and lanthanum mixture The hydrofluoric acid solution keeps the ratio of fluoride ion to metal ion (the sum of barium ion and lanthanum ion) at 22.5, and stirs vigorously while adding the hydrofluoric acid solution. After it was filtered and washed twice with water, a white precipitate was obtained. Transfer the obtained white precipitate to a blast drying oven at 100°C for 12 hours. After the residual liquid is completely removed, place it in a muffle furnace, raise the temperature to 800°C at a rate of 2°C / min and keep it for 2 hours, then The composite barium lanthanum fluoride catalyst can be obtained by lowering the temperature by itself.

Embodiment 3

[0039] Embodiment 3: catalyst preparation

[0040] First take 39g of barium nitrate and 43.3g of lanthanum nitrate and dissolve them (the molar ratio of barium to lanthanum is Ba:La=3:2) in 500ml of distilled water, heat and stir in a water bath at 80°C, and at the same time slowly add diluted Keep the ratio of fluoride ion to metal ion (the sum of barium ion and lanthanum ion) of hydrofluoric acid solution at 22.5, stir vigorously while adding it, and filter it when the hydrofluoric acid solution is added dropwise and there is no more colored precipitation After washing twice with water, it was transferred to a 100°C blast drying oven to dry for 12 hours. After the residual liquid was completely removed, it was placed in a muffle furnace, and the temperature was raised to 800°C at a heating rate of 2°C / min and kept for 2 hours, and then The composite barium lanthanum fluoride catalyst can be obtained by lowering the temperature. Finally, it is pressed into a tablet at 20 MPa ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com