Method for strengthening caproic acid fermentation by exogenously adding inorganic carbon source

An inorganic carbon source, calcium carbonate technology, applied in the field of waste recycling, can solve the problems of high salt, high cost, accumulation and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: the production of caproic acid fermented liquid

[0049] The raw materials used in the experiment are the naturally acidified fermentation broth and the inoculated sludge fermentation mixture obtained in the patent application number 201911354619.1, wherein:

[0050] Natural acidification group: first add water to the fruit and vegetable waste to obtain a fermentation system with a total solid concentration (TS) of 8% and a volatile solid (VS) content of 78g-VS / L, and then place the fermentation system at a temperature of 34 to Ferment for 17 days under the conditions of 36° C., pH 4.0-4.5, and rotation speed 60 rpm to obtain a fermentation liquid (this fermentation liquid is ethanol-type acidified fermentation liquid).

[0051] Inoculation sludge group: first add water to the fruit and vegetable waste to obtain a fermentation system with a total solid concentration (TS) of 8% and a volatile solid (VS) content of 78g-VS / L, and then use 70g-VS / L Inoculum a...

Embodiment 2

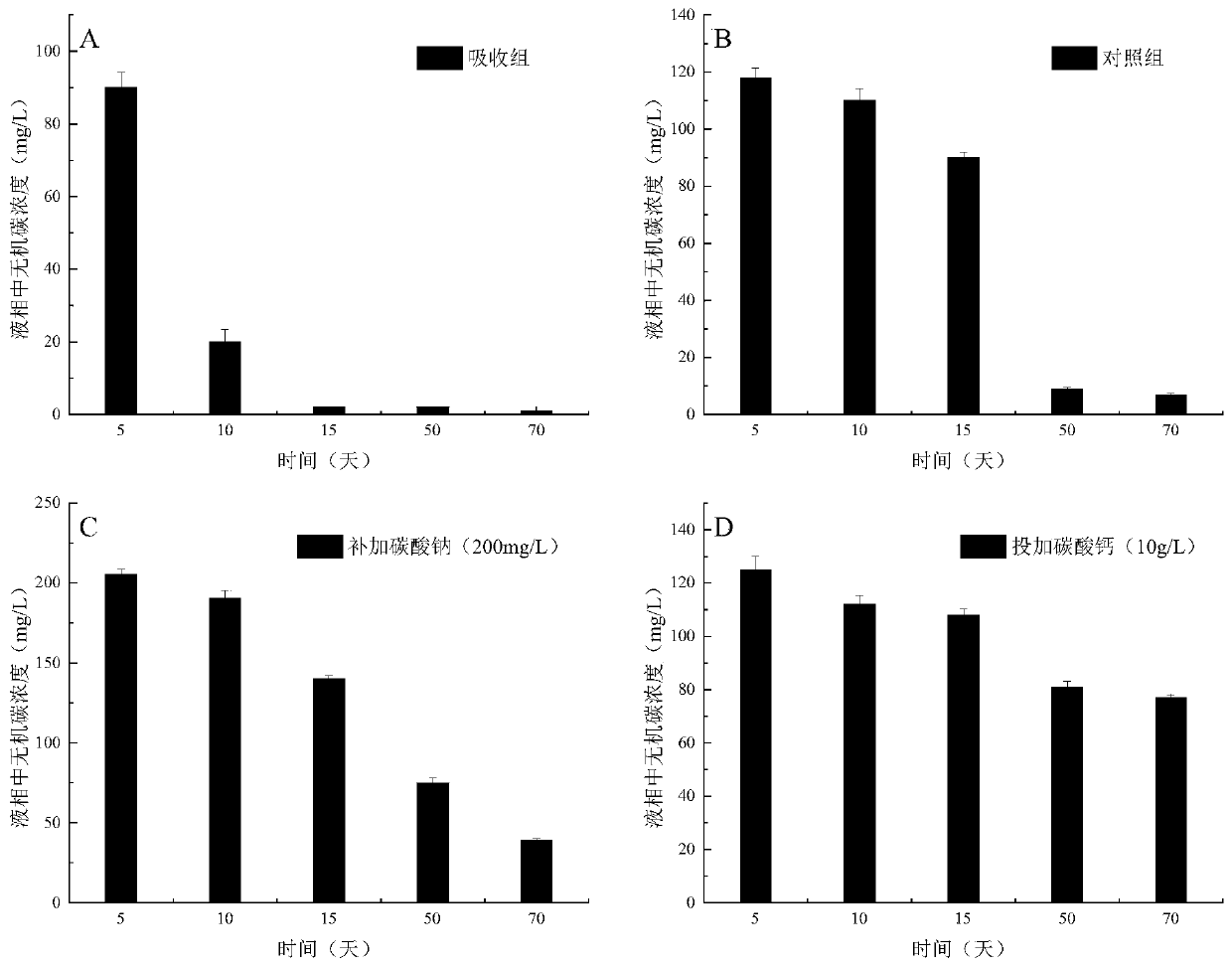

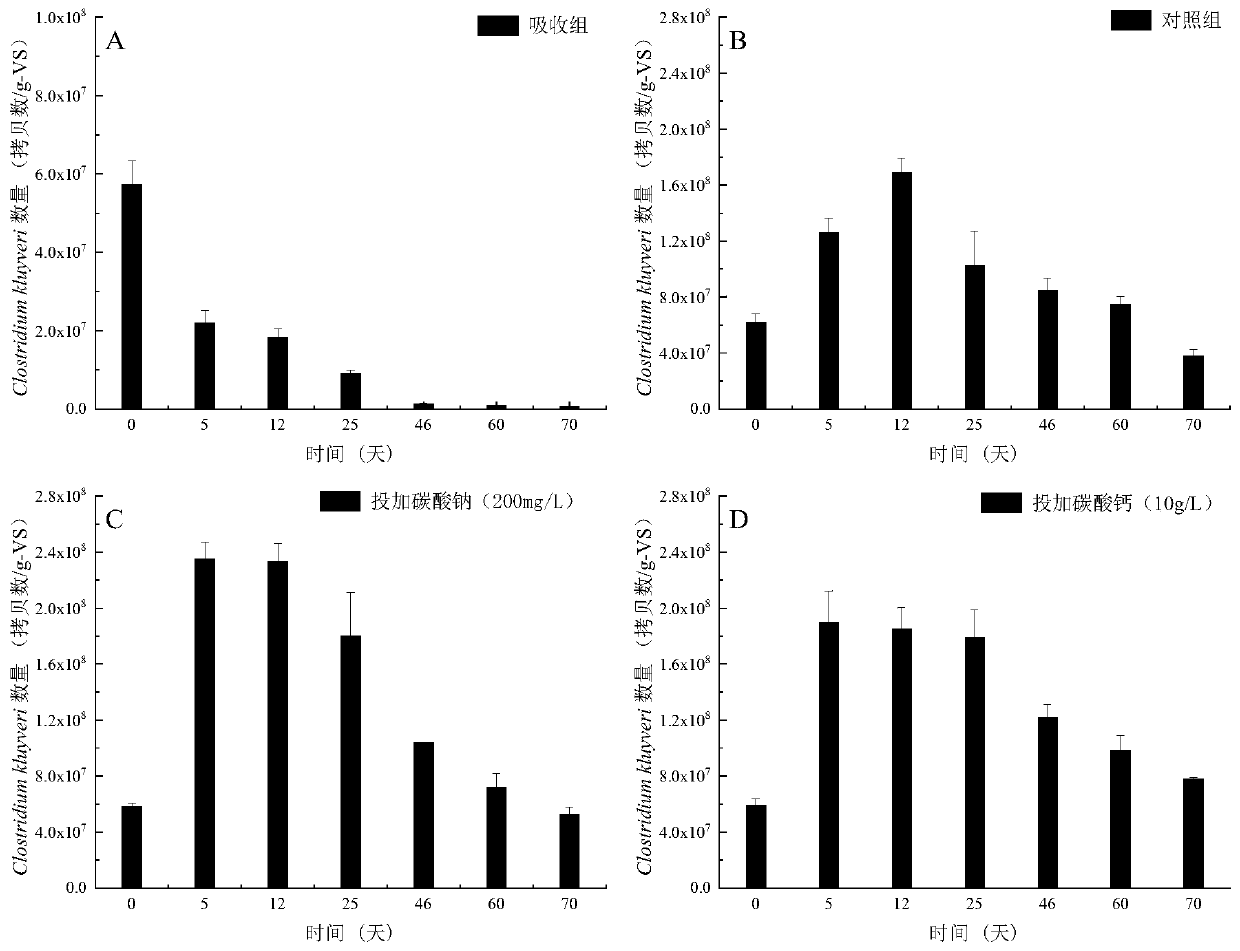

[0053] Embodiment 2: the selection of inorganic carbon source

[0054] Add inorganic carbon source in the fermented mixed solution that finally obtains that embodiment 1 obtains, can be divided into CO 2 Absorption group, blank control group, Na 2 CO 3 (200mg / L) dosing group and CaCO 3 (10g / L) group (the carbon concentration of the two groups is basically the same). The CO in which the experiment was set up 2 The realization method of the adsorption group is: the top of the anaerobic caproic acid fermentation device is connected with the device for carrying saturated sodium hydroxide solution, while the reaction devices of the remaining experimental groups are connected with 3mol / L phosphoric acid solution (pH is about 3, which is lower than that of saturated carbonic acid solution). pKa, ensure no CO 2 Dissolved in water), regularly sample and detect the liquid phase products, aiming at the number of homoacetogenic bacteria and hydrogen-eating methanogenic bacteria in di...

Embodiment 3

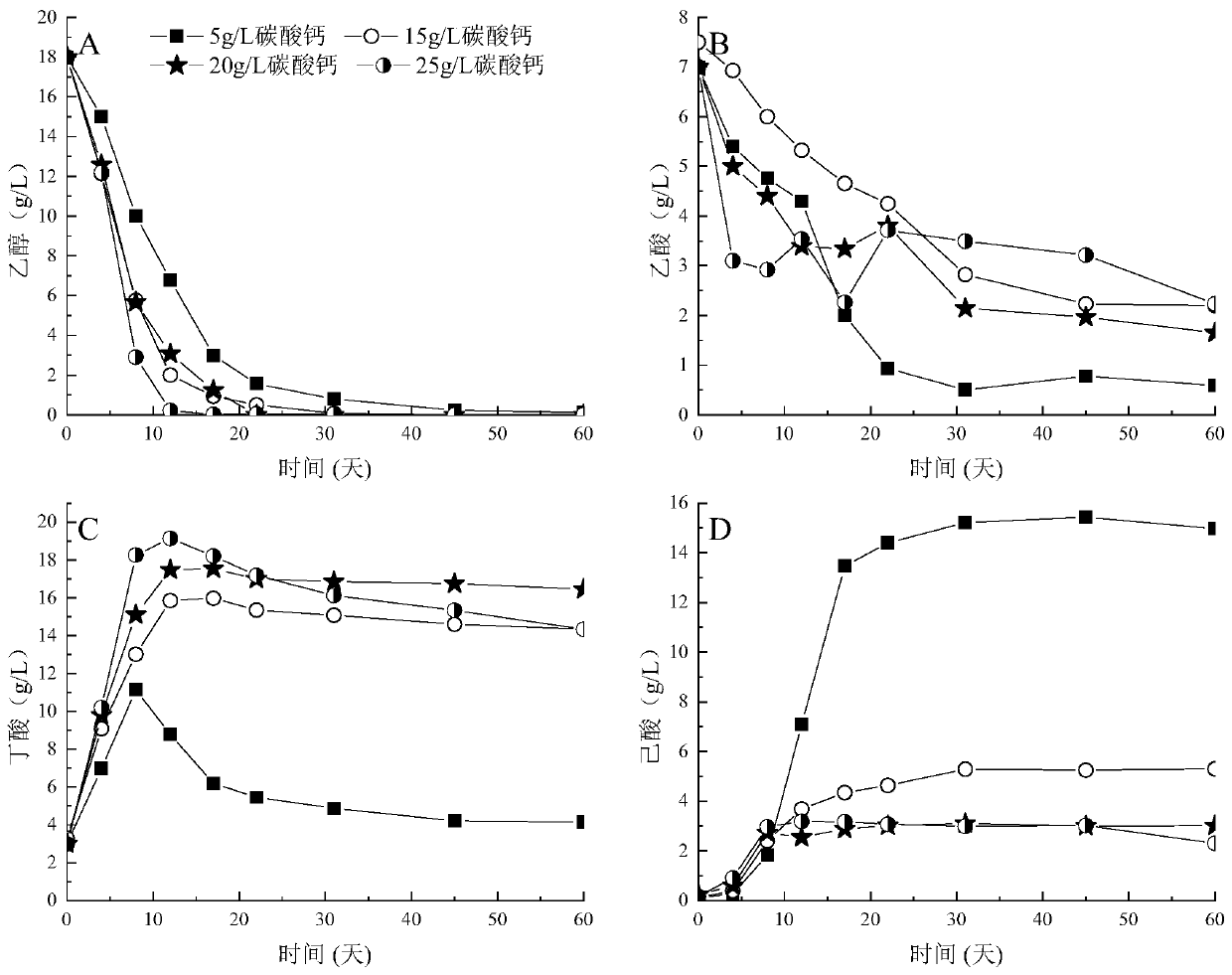

[0063] Embodiment 3: the selection of calcium carbonate dosage

[0064] Adopt the method of embodiment 2, set different calcium carbonate dosage gradients as experimental variable, set and add 5,15,20,25g / L CaCO respectively 3 Dosing amount of calcium carbonate as different concentrations. Samples were taken regularly for detection, and biophase samples were taken for the number of homoacetogenic bacteria and hydrogen-eating methanogens in different periods of time by fluorescence quantitative PCR and high-throughput sequencing.

[0065] The initial pH was adjusted by adding 3mol / L NaOH from an external source, and it was controlled at 7.5±0.1, and the temperature was controlled at 30°C. The headspace was evacuated with nitrogen for 5 minutes before the reaction was started to ensure an anaerobic environment in the reaction apparatus. Liquid sampling is performed by anaerobic extraction with a needle syringe, and the obtained liquid is sealed and stored at 4°C for a short pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com