Method for directionally producing succinic acid by CO2 biotransformation

A technology for biotransformation and production of succinic acid, applied in the direction of microorganism-based methods, biochemical equipment and methods, chemical instruments and methods, etc., can solve problems such as difficulty in succinic acid, low solubility, and poor directional transformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

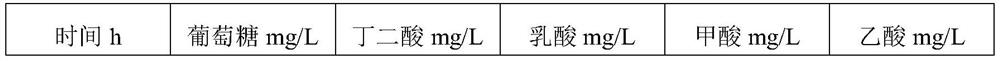

Embodiment 1

[0112] a CO 2 The method for the directional production of succinic acid through biotransformation, the concrete steps are as follows:

[0113] 1) Pipette 5 mL of the pure strain A. succinogenes 130Z solution and insert it into 100 mL of growth medium sterilized by high pressure steam at 121°C for 20 minutes for cultivation. The formula of the growth medium is: 0.75g potassium dihydrogen phosphate, 0.75g dipotassium hydrogen phosphate, 0.45g 2-ethanesulfonic acid, 5g yeast extract, 2.5g corn steep liquor, 0.006g sodium selenite, 1.008 g sodium chloride, 0.008g sodium tungstate, 0.5g sodium hydroxide, 1.5g ferrous chloride tetrahydrate, 0.19g cobalt chloride hexahydrate, 0.1g manganese chloride tetrahydrate, 0.07g zinc chloride, 0.006g Boric acid, 0.036g sodium molybdate, 0.024g nickel chloride hexahydrate, 0.002g copper chloride dihydrate, 0.5g magnesium chloride hexahydrate, 0.3g ammonium chloride, 0.3g potassium chloride, 0.015g calcium chloride dihydrate, 10mg Resazurin (...

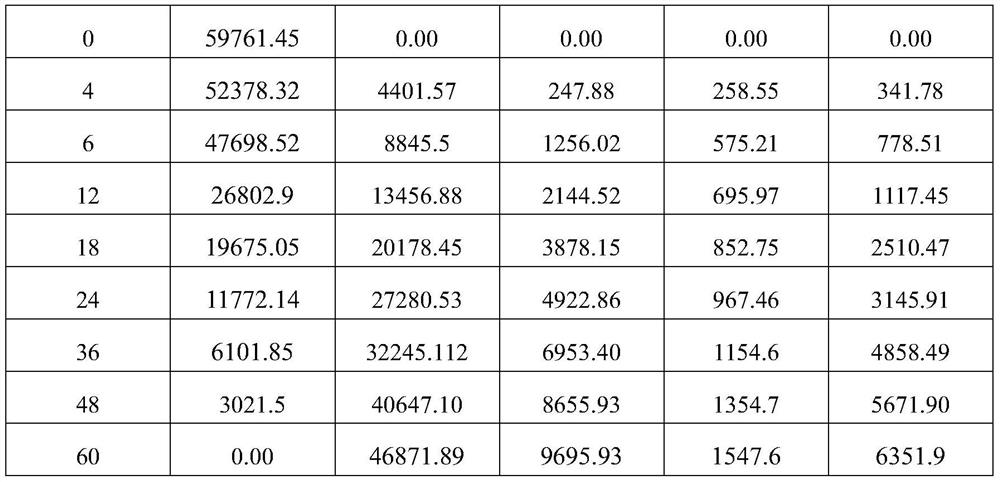

Embodiment 2

[0133] a CO 2 The method for the directional production of succinic acid through biotransformation, the concrete steps are as follows:

[0134] 1) Pipette 5 mL of the pure strain A. succinogenes 130Z solution and insert it into 100 mL of growth medium sterilized by high pressure steam at 121°C for 20 minutes for cultivation. The formula of the growth medium is: 0.75g potassium dihydrogen phosphate, 0.75g dipotassium hydrogen phosphate, 0.45g 2-ethanesulfonic acid, 5g yeast extract, 2.5g corn steep liquor, 0.006g sodium selenite, 1.008 g sodium chloride, 0.008g sodium tungstate, 0.5g sodium hydroxide, 1.5g ferrous chloride tetrahydrate, 0.19g cobalt chloride hexahydrate, 0.1g manganese chloride tetrahydrate, 0.07g zinc chloride, 0.006g Boric acid, 0.036g sodium molybdate, 0.024g nickel chloride hexahydrate, 0.002g copper chloride dihydrate, 0.5g magnesium chloride hexahydrate, 0.3g ammonium chloride, 0.3g potassium chloride, 0.015g calcium chloride dihydrate, 10mg Resazurin (...

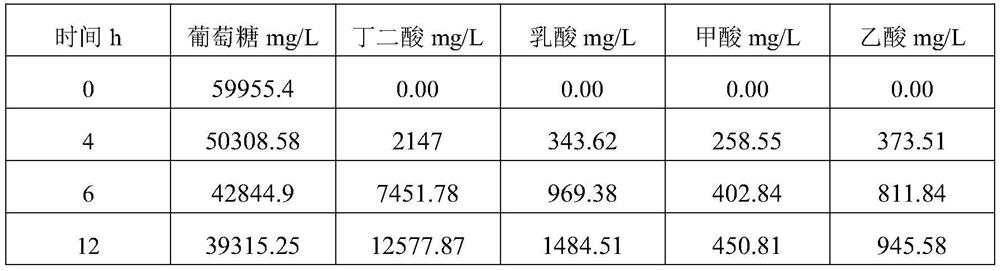

Embodiment 3

[0155] Repeat Example 2, the difference is that in step 6), the acid neutralizer in the mixed biological fermentation system is calcium carbonate.

[0156] The fermentation system of this embodiment will CO 2 The analysis results of liquid substances biotransformed into succinic acid are shown in Table 3 below:

[0157] Table 3: Analysis results of liquid substances in the reactor

[0158] time h Glucosemg / L Succinic acidmg / L Lactic acidmg / L Formic acidmg / L Acetic acidmg / L 0 59982.09 0.00 0.00 0.00 0.00 4 52855.52 1521.68 234.65 358.15 481.81 6 482541.34 13478.27 271.73 1216.12 1487.28 12 343885.07 22902.49 865.19 2651.67 5290.05 18 264550.41 23453.86 4598.52 3705.1 6040.21 24 188753.7 35024.81 4821.61 4236.74 6028.78 36 9983.71 38323.20 5692.77 5200.2 6720.54 48 10547.9 39776.54 7254.56 6313.41 7631.26 60 6547.8 40578.43 8902.56 7954.8 8457.9 72 0.00 42861.49 9595.93 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com