High-salt diluted oyster brewed soy sauce

A technology for high-salt dilute soy sauce and oysters, applied in food science and other directions, can solve problems such as the reproduction of miscellaneous bacteria that cannot be solved, and achieve the effect of obvious marine flavor, rich seafood aroma, significant nutritional effect and excellent flavor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

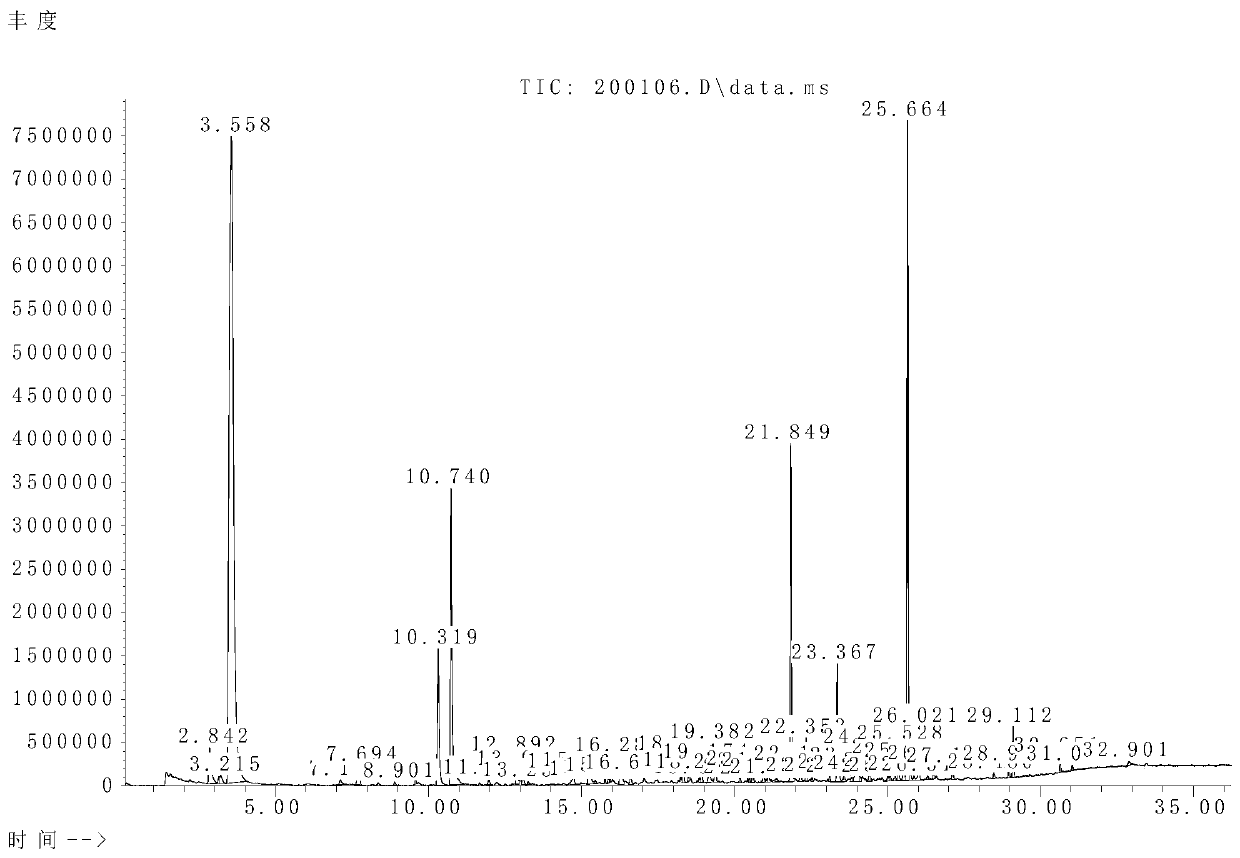

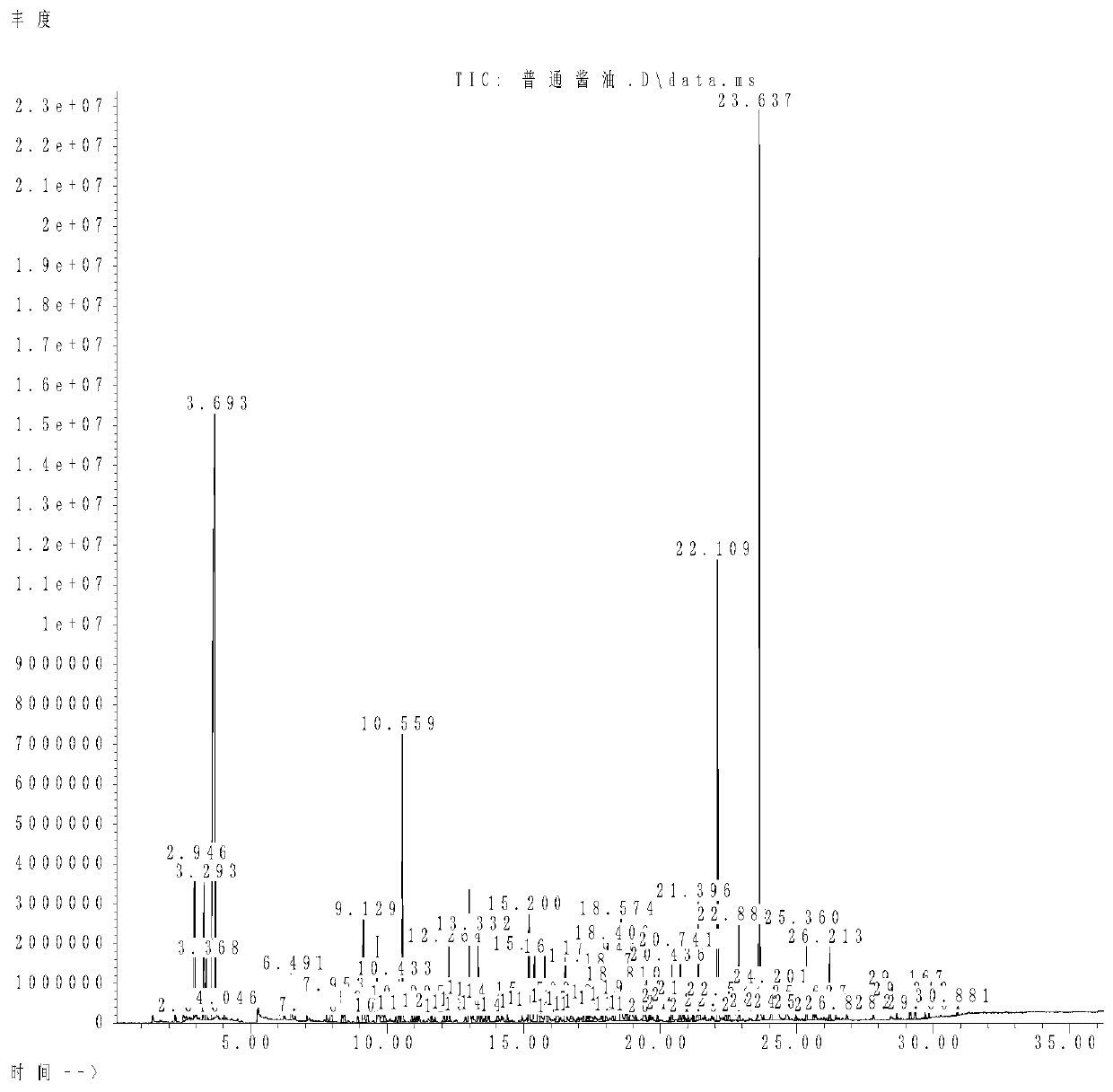

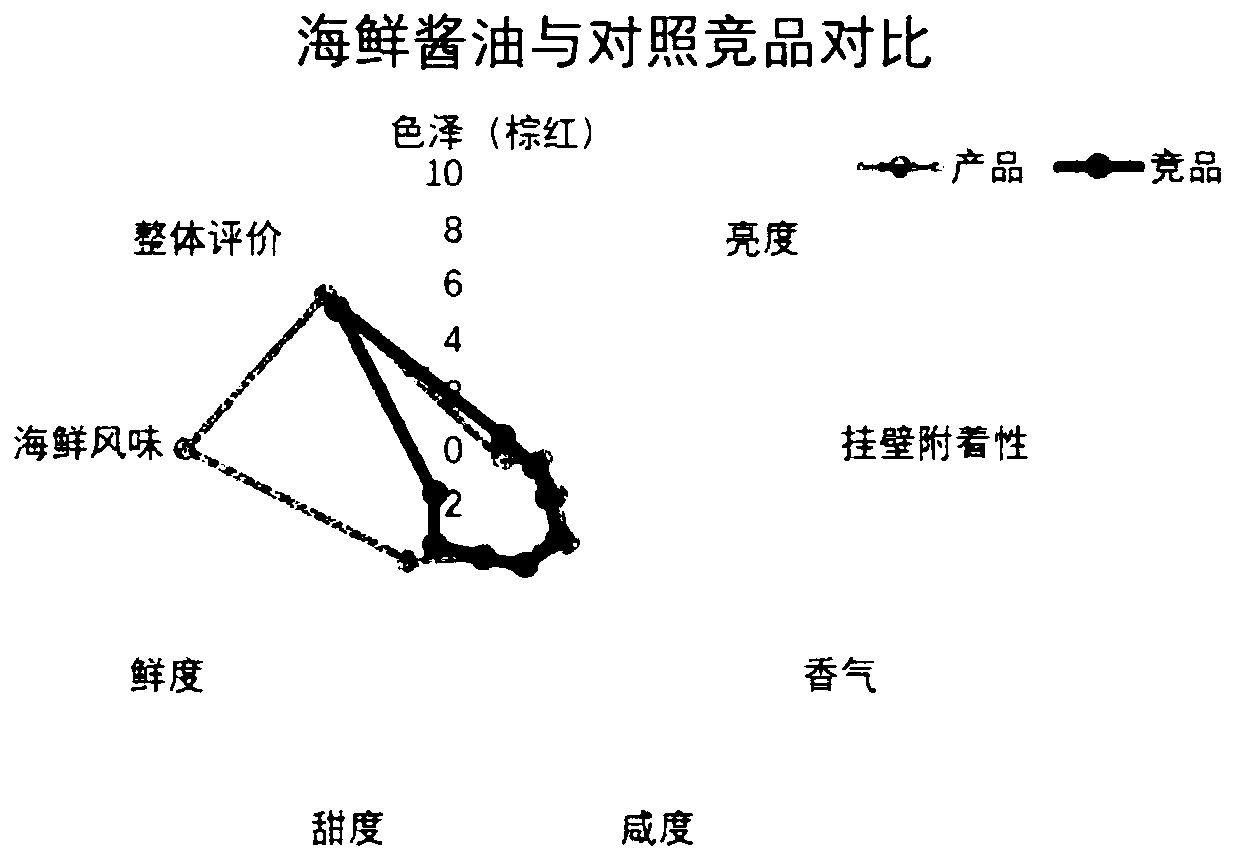

Image

Examples

preparation example Construction

[0032] (1) Preparation of oyster homogenate: use fresh oysters, add deionized water at a ratio of 1:1-1:10 after washing, mix well and then add 10%-12% sodium ascorbate solution to it for beating , The amount of sodium ascorbate added is 20%-25% of the oyster mass. Homogenize with a homogenizer to make oyster homogenate.

[0033] (2) Preparation of oyster enzymatic hydrolyzate: fresh oysters are washed, beaten, and prepared by biological treatment, ie microbial fermentation to produce enzymes and / or protease preparations.

[0034] The microbial fermentation treatment of the above-mentioned oyster enzymolyzed solution refers to adopting fermentation to produce protease, with oyster homogenate as microbial nutrient substance, microorganism uses neutral protease producing bacteria, acid protease producing bacteria, alkaline protease producing bacteria, such as bacillus (such as subtilis Bacillus, Bacillus cereus, Bacillus licheniformis, Bacillus natto, etc.), yeast (such as brew...

Embodiment 1

[0043] Embodiment 1 uses oyster fermented liquid to prepare soy sauce

[0044] Fresh oysters are shucked, cleaned, blackened and viscera removed, and then beaten with a little water. After beating, add water and mix according to the material-to-liquid ratio of 1:1-10:1, add protease-producing strains (Bacillus subtilis, CGMCC1.14985) to carry out fermentation treatment, and the inoculation amount is 0.1%-3% of oysters, at 25 Ferment for 5-24 hours at -50°C. Sterilize at 95°C for 30 minutes to obtain the oyster fermentation broth, and store it at 4°C for future use.

[0045] Weigh 75g of preferred soybean meal and 25g of wheat, add 60mL of water, sterilize and cool to room temperature, insert Aspergillus oryzae, and make koji at 25°C for 12-36h. Prepare 23% saline and cool down to 4°C. Saturated low-temperature brine and koji are mixed into tanks for fermentation. On the second day after the soy mash was put into the tank, it was stirred once with compressed air, and the ga...

Embodiment 2

[0065] Fresh oysters are shucked, cleaned, blackened and viscera removed, and then beaten with a little water. After beating, mix with water according to the material-to-liquid ratio of 1:1-10:1, add protease, the amount of enzyme added is 0.1%-5% of the oyster, and enzymatically hydrolyze for 2-15 hours at 25-50°C. Sterilize at 95°C for 30 minutes, store at 4°C for future use.

[0066] Weigh 75g of the preferred soybean meal and 25g of wheat, add 60mL of water, sterilize and cool to room temperature, insert Aspergillus oryzae, and make koji at 30°C for 12-36h. Prepare 18% saline, sterilize, cool down, and set aside. Then mix 0.5-30mL of the oyster hydrolyzate hydrolyzed by protease, and prepare oyster soy sauce according to the process of Example 1. The final salt concentration of the original soy sauce was 0.16-0.165g / mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com